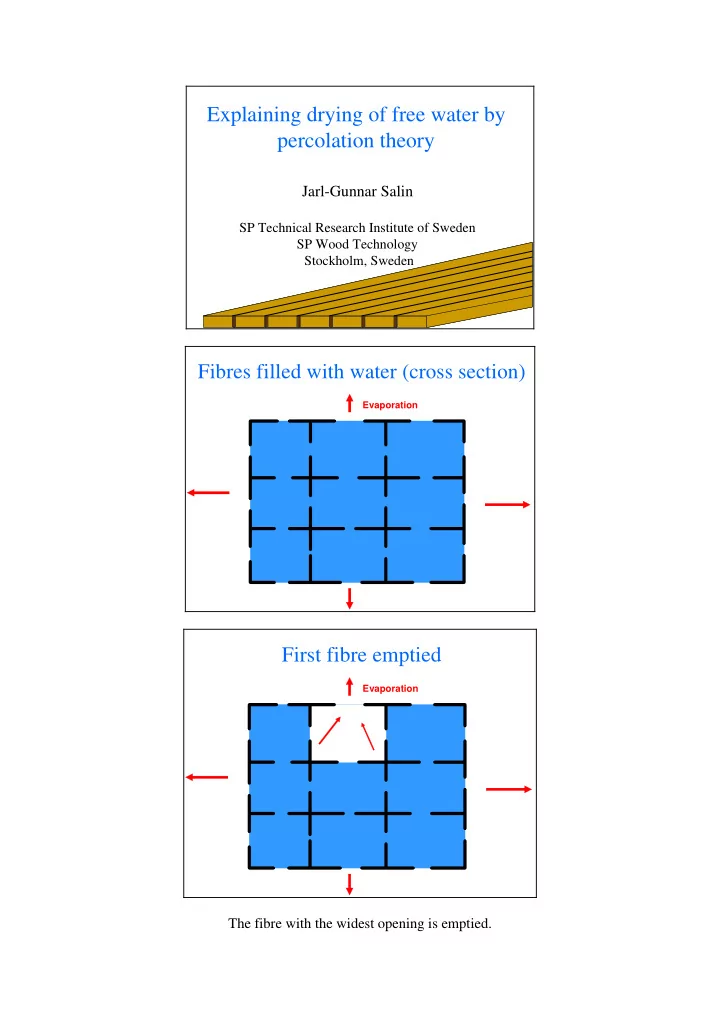

Explaining drying of free water by percolation theory Jarl-Gunnar Salin SP Technical Research Institute of Sweden SP Wood Technology Stockholm, Sweden Fibres filled with water (cross section) Evaporation First fibre emptied Evaporation The fibre with the widest opening is emptied.

Second fibre emptied Evaporation Again the fibre with the widest opening is emptied – not the one with the highest evaporation. Drying from two sides of a 100 x 180 square network Continues.

The water phase is gradually fragmentized. No clear receding front – as in a typical diffusion process – is seen.

Evaporation from the upper and lower surfaces of a 30 x 30 x 98 fibre network. Process continued. Adaptation to softwood 1. Comstock fibre model (hexagonal and rectangular cross sections). 2. Only 20 % of the tangential walls assumed to have openings. 3. Radial ray cells (5 %) introduced. 4. Different diffusion coefficients in the principal directions of the “dry” region are taken into account. 5. Periodic 3-dimensional network. 6. Opening (bordered pit) size and lumen volume are stochastic variables

Moisture profiles in the radial direction in a initially saturated 60 x 60 x 98 fibre network 180 160 Moisture content, % 140 120 100 80 60 40 20 0 0 20 40 60 80 100 Radial distance Drying takes place from both vertical sides in the diagram. In the beginning “gradient-free” drying is seen, which stops at a rather well defined point and receding fronts are formed. Moisture profiles in the tangential direction in a initially saturated 60 x 60 x 98 fibre network 180 160 Moisture content, % 140 120 100 80 60 40 20 0 0 20 40 60 80 100 Tangential distance Density profiles obtained by CT-scanning of a piece of wood during drying The gradient-free drying behaviour is clearly seen in this experiment.

Important result • “Gradient free” profiles are quickly developed in the beginning. • At a certain threshold point a receding front process starts instead. • This point corresponds to the breakdown of the continuous water cluster and corresponds to “irreducible saturation” introduced by Spolek and Plumb. “The ant and the tiled terrace”- problem A man wants to cover his big terrace with white and black tiles. He asked for offers from several workers and the cheapest one was chosen. The worker was however blind and the tiles were put in a stochastic order without any structure. An ant wants to cross the terrace from one side to the opposite side. It is a clever ant and it walks only on black tiles as it would be clearly seen by the birds on a white background and picked for food. What should the ratio of black tiles be in order to provide a path for the ant? For large networks there is a certain ratio, “percolation threshold” above which a path is established. In the same manner, if the ratio of water filled fibres in wood exceeds a certain value, a continuous water phase is established – otherwise not.

59,68 % black tiles (critical value = 59,2746 %) Location of evaporation front. Kiln brown stain 50 40 evaporation Relative 30 20 10 0 1 3 5 7 9 11 13 15 17 19 Fibre layer Location of evaporation front, damaged wood surface 40 35 evaporation 30 Relative 25 20 15 10 5 0 1 5 9 13 17 21 25 29 33 37 41 45 49 Fibre layer

Influence of damaged wood surface. Kiln brown stain 180 Moisture content, % 160 140 120 100 80 60 40 20 0 0 40 80 120 160 Radial distance Drying rates for radial drying 1 0,9 0,8 Relative drying rate 0,7 0,6 0,5 0,4 0,3 Undamaged 0,2 Damaged 0,1 0 160 140 120 100 80 60 40 20 0 Moisture content, % Drying rates for tangential drying 1 0,9 0,8 Relative drying rate 0,7 0,6 0,5 0,4 0,3 0,2 Undamaged 0,1 Damaged 0 160 140 120 100 80 60 40 20 0 Moisture content, %

Relative permeability in the tangential direction 1 0,9 Gas Relative permeability 0,8 Liquid 0,7 0,6 0,5 0,4 0,3 0,2 0,1 0 0 0,2 0,4 0,6 0,8 1 Water saturation Relative permeability in the radial direction 1 0,9 Gas Relative permeability 0,8 Liquid 0,7 0,6 0,5 0,4 0,3 0,2 0,1 0 0 0,2 0,4 0,6 0,8 1 Water saturation Relative permeability – sample size effect 1 0,9 Relative permeability 30x30x10 0,8 30x30x38 0,7 30x30x98 0,6 0,5 0,4 0,3 0,2 0,1 0 0 0,2 0,4 0,6 0,8 1 Water saturation

Film flow phenomenon Film flow phenomenon Film flow incorporated 180 160 Moisture content, % 140 120 100 80 60 40 20 0 0 5 10 15 20 25 30 35 40 Radial distance

Conclusions • The invasion percolation approach can be used to describe drying of free water in the fibre structure of solid wood. • It explains or increases the understanding of at least these items: – Gradient free drying – Percolation threshold – Dry shell development – Apparent reduced external mass transfer – Kiln brown stain – Relative permeability – Shrinkage above FSP More information: jarlgunnar.salin@sp.se

Recommend

More recommend