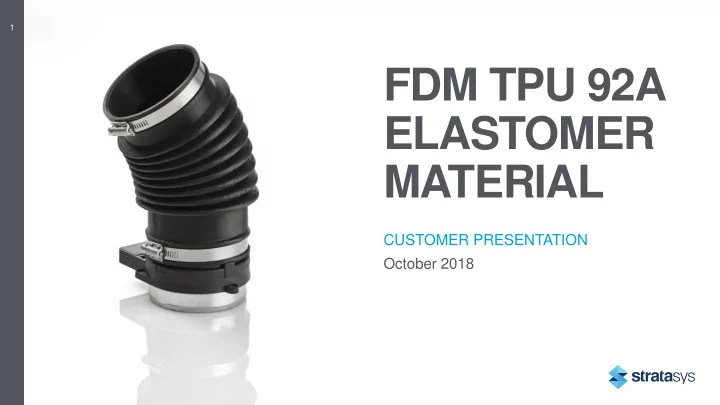

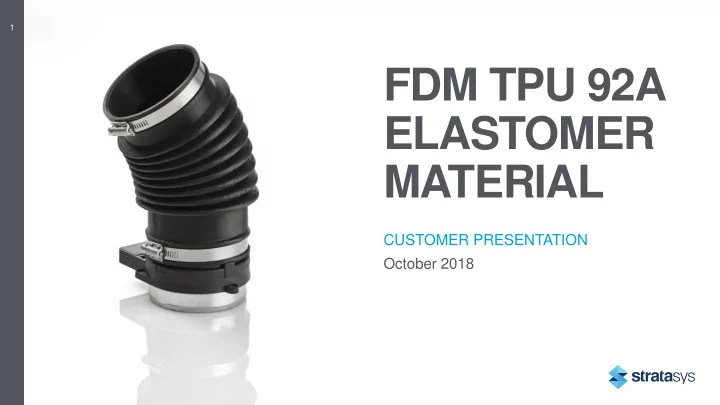

1 FDM TPU 92A ELASTOMER MATERIAL CUSTOMER PRESENTATION October 2018

2 ELASTOMERS Stratasys

3 What are elastomers? Elastomer Materials Key difference between elastomers and rigid polymers - RESILIENCE – the ability to stretch or compress greatly and not lose its shape Thermoplastic Polyurethane Elastomer TPU is a type of elastomer material – a polymer with the property of elasticity Broad range of TPUs, from soft to rigid TPU is renowned for: High elongation, superior toughness, extreme Stratasys durability

4 Current elastomer prototyping options Not ideal Low-priced FFF Traditional Manufacturing Non-FDM Technologies Additive Manufacturing Molding, casting Additive Manufacturing Stratasys SLS, CLIP, MJP

5 Elastomer prototyping technologies available today Traditional Methods High cost and limited geometries with molded / cast parts Typically one week and $1K minimum Can’t create complex geometries Non-FDM AM Limited build size with CLIP, limited material properties with SLS / Jetting Higher total part cost Internal or external service bureau queues Low-Priced FFF Manual support removal can be labor intensive and result in poor support interface surfaces Limited part complexity and build size Printer price may be low, but TCO is high Stratasys

6 Imagine… Quick turn around Get elastomer parts in hand in a matter of hours versus days Elastomer prototyping Large build size that delivers Produce the size you need - larger prototype capabilities Complex designs Create complex geometries not possible with other additive manufacturing options Reliable Highly functional elastomer material that reliably produces complex and accurate prototypes Cost effective Build all prototypes (elastomer and other thermoplastics) on a single system with fast, easy material changeovers Easy to use User-friendly software with quick learning curve - no dedicated Stratasys operator needed

7 Engineers need fast, large, accurate, functional, & complex elastomer parts - quickly & easily Stratasys

8 Introducing FDM TPU 92A Elastomer on the Stratasys F123 Series™ Printer Stratasys

9 Now possible only from Stratasys The only elastomer material with REAL soluble support on the easiest to use rapid prototyping 3D printer Stratasys

10 FDM TPU 92A Elastomer Material Large and complex elastomer parts on the easiest-to-use prototyping solution Stratasys Stratasys F123 Series Adding greater value to our newest product line

11 FDM TPU 92A Making the complex easy…with Stratasys soluble support Competitors’ subpar support makes their part production cost Build large elastomer parts 1.8X MORE Stratasys’ hands - Build the parts you free soluble support need, and not just the decreases labor parts your prototyping costs by 76% system makes Stratasys

12 FDM TPU 92A Large and complex parts, consistently and reliably built Complex geometries Consistent and reliable accuracy Exceptionally resilient material with very high elongation Large and complex parts Stratasys

“ 13 Quote from beta customer “Build quality was much better than elastomers on alternate FDM/FFF platforms. Build success rate was also 100%. The parts printed right the first time.” Stratasys

14 Automotive applications Sample Parts Stratasys

15 Beta customer quotes “Parts are virtually indestructible ” “ Everyone is excited about this material , especially in the manufacturing groups.” “Used to have to find work -arounds for elastomer parts, now can design for it .” “We didn’t know how badly we needed this material until we started using it!” “Being able to print parts quick and easy in -house. Our customers are very impressed with our new capabilities.” “ Best elastomer I have experienced.” Stratasys

16 F123 Series printer options Stratasys F170 Stratasys F270 Stratasys F370 Includes: PLA Kit Includes: PLA Kit Includes: Elastomer Extrusion Kit Stratasys Optional : Elastomer Extrusion Kit Optional : Elastomer Extrusion Kit Optional: PLA Kit

17 F123 Series extrusion heads Standard Extrusion Head PLA Extrusion Head Elastomer Extrusion Head PN: 123-00300 PN: 123-00307 PN: 123-00320-S Black Housing Gray Housing Blue Housing Stratasys Standard on F170, F270, 370 Standard on F170, F270 Standard on F370

FDM 18 FDM TPU 92A FDM TPU 92A™ is an FDM elastomer which is a highly sought-after material used in the auto industry, as well as other industries requiring flexible plastic parts used during the prototype and design phases. Properties ▪ FDM elastomer material ▪ Flexible and tear resistant material – ▪ Elongation of 500% ▪ T ear strength 84 Kn/m (480 lbF/in) ▪ Industries – automotive, industrial, consumer products, sporting goods ▪ Available on the F123 Series Printers T op User Applications • Hoses / tubes / air ducts • Console liners / cup holders • Seals / gaskets / grommets • Grips / surface protection covers • Bellows • Stratasys Door and window trim / seals • Body panel seals / gap hiders

19 Thank You Stratasys

“ 20 Appendix Stratasys

21 Competitive Comparison Study Comparison of • Three different parts • Three different levels of complexity Stratasys

22 Competitive Elastomer AM Study 3 parts with different levels of complexity were evaluated Low Medium High Complexity Complexity Complexity • Fairly simple design • • Multiple curved surfaces Large size • Small to medium size • • Stratasys Internal and external Internal cavities • Limited support required • support required Complex geometries • Requires soluble support

23 Compared printers Printers: • Carbon • EOS • Lulzbot Ultimaker (FFF) Carbon (DLS) • Ultimaker (III & S5) • Cubicon Materials: EOS (SLS) • Ninjaflex & Polyflex (makers) • Duraform (SLS) • Carbon TPU (DLS) Lulzbot (FFF) What we compared: Cubicon (FFF) • Material Costs • Labor Costs • Total Costs Stratasys • Equipment Cost

24 Material costs Material costs are only part of the story Part Material Costs $80 $70 $60 • SLS costs are even $50 lower than FDM makers $40 • Use of soluble support $30 drives F123 material costs up $20 $10 $0 F123 SLS TPU Carbon TPU All Makers Low Complexity Med Complexity High Complexity Stratasys

25 Labor costs F123 hands-free soluble support key Labor Costs $140 to low labor costs $120 $100 F123 labor costs $80 average $60 76% $40 Lower $20 than competitors $0 F123 SLS TPU Carbon TPU All Makers Low Complexity Med Complexity High Complexity Stratasys

26 Total part costs F123 part and labor costs deliver lowest Total Part Costs with Labor & Material total part cost $200 $180 $160 $140 F123 labor and material $120 costs average $100 39% $80 $60 Lower $40 than competitors $20 $0 F123 SLS TPU Carbon TPU All Makers Low Complexity Med Complexity High Complexity Stratasys

27 F123 wins on equipment Equipment costs per year costs over Printer and Post-processing time $60.000 $50.000 78-93% $40.000 F123 is Lower Equipment Cost Per Year Than SLS and Carbon 1/6 price of SLS $30.000 and $20.000 1/8 price of Carbon $10.000 $0 Makers* F170 F270 F370 SLS Carbon** Stratasys *With high volume use, maker printers would need to be replaced yearly ** Based on yearly subscription fees

33 Elastomer Extrusion Kit Contents: • Custom elastomer extrusion head (blue). • 1 spool TPU 92A filament, black, 60 ci • 2 Upper Y-block parts • Brochure with install instructions • Web address to download the FDM TPU 92A Best Practices document The kit can be installed by customers Stratasys

Recommend

More recommend