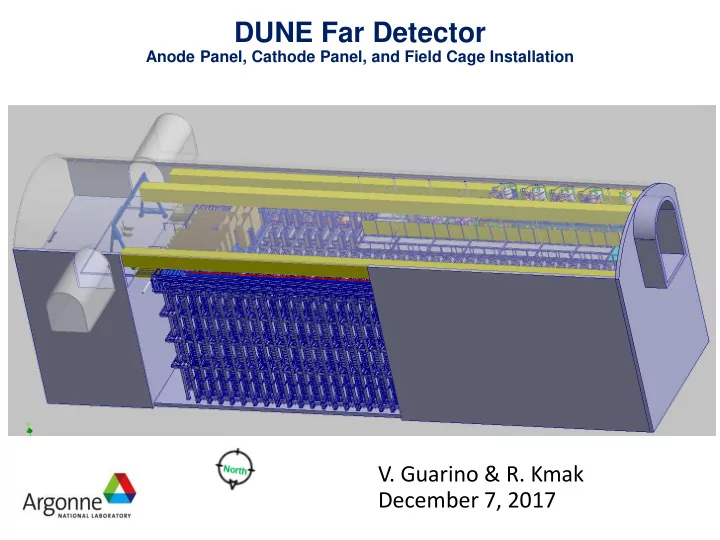

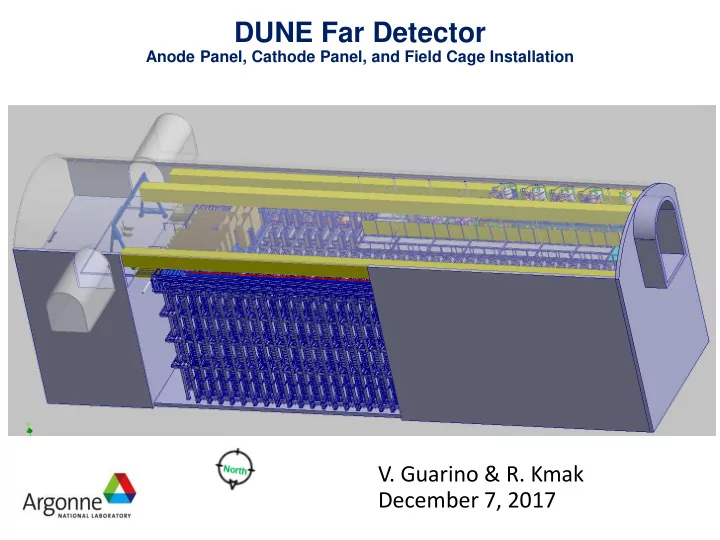

DUNE Far Detector Anode Panel, Cathode Panel, and Field Cage Installation V. Guarino & R. Kmak December 7, 2017

DUNE Installation • Define Requirements for Underground Installation • Define detector components and identify space • Assumptions and requirements of detector crates • Description of present concept of detector assembly and installation • Work in the toaster area 2

DUNE Far Detector Weekly Installation Goal to Meet Current Schedule Components will be moved into the Clean Room in sufficient quantities to assemble & install ‘one set’ of panels as shown. A.k.a. ‘ 1/25 TH assembly. 3

Facility Requirements • Crane • Need 6.5m hook height to install 4m long CPA with rigging. • Need 6m hook height to remove APA’s vertical out of crate • Need two hoists that can transverse North-South to rotate APA’s. Dual hoists need to be able to get within 1m of each other • Need north-south coverage for 2-3 work stations • Need class 100,000 “Gray Room” (Could be achieved with Uni-Strut Frame and plastic sheeting) • Need storage space for 1 week of installation underground • Crates need to be stored within the foot print of crane coverage 4

DUNE Far Detector Facility & Components Anode Panel Assembly (APA) ~12 m tall Cathode Panel Assembly (CPA) Field Cage (FC) ~12 m tall Some features and / or components Access may or may not be shown on Door subsequent slides for clarity. Gantry Crane Person Footbridge Person Lower Assembly Area a.k.a. ‘Toaster’ Upper Assembly Area a.k.a. ‘Pedestal’ Cryostat Clean Room Boundary Clean Room Boundary 5

Gantry Crane • Gantry will run East-West on fixed rails and cover pedestal and cryostat. • Two 3 tons hoists with dual speeds for smooth motion • Hoists and gantry will be driven • Meets requirements for coverages • $68k Dearborn Crane • 15fpm hoist speed so ~3m from pedestal to pit floor 6

DUNE Far Detector Assembly Area / Clean Room Boundaries 7 Plan View - All Dimensions are Estimated

DUNE Far Detector Assembly Area / Clean Room Boundaries Elevation View, Looking East to West. All Dimensions are Estimated 8

Crates • Crates need to be able to be rotated 180 degrees and hung from ends – challenge for crate design • Max Crate Loads • Height – 3.6m • Depth – 3.7m • Width – 1.38m • Weight 13,00lbs • Crates will be transported to cavern on carts 18” high. • Wooden crates not allowed in cleanroom • North drift needed to remove outer shell of crates? 9

DUNE Far Detector Assumed APA and FCA Crate Sizes and Capacity Lower 1/3 panel Middle Upper 1/3 panel Upper 1/3 panel CPA – one complete panel per shipping Crate covers container, shipped in ~4m sections not shown APA – one complete panel per shipping container, shipped in ~6m sections 10

DUNE Far Detector Assumed FC Crate Size and Capacity FC Crate has an inner structure to support the FC. Top and sides removed tor loading & unloading of FCs Loaded Crate (top not shown) FC – two complete panels per shipping container Upper panels packaged ‘hinges UP’ Lower panels shipped ‘hinges DOWN’. 11

DUNE Far Detector Panel Components Staged in Clean Room 12

Detector Assembly and Installation • APA’s • 2 APA’s per crate • Top and bottom APA’s installed using a fixture that holds APA’s for cable routing and physical connection • Assume PD and electronic boxes are installed and no cables are connected. • Minimal testing after APA pair assembled • CPA’s • Three CPA modules that are 4m long are connected using a fixture. • FC modules attached to CPA pair in toaster 13

DUNE Far Detector APA UNPACKING & CONSTRUCTION 1) Half (~6m) of APA removed from crate 2) Rotated to stand vertically 4) Lowered into Assembly fixture 3) Rotated to align with assembly fixture APA crates are not designed so assuming vertical lift out of crate 14

DUNE Far Detector CPA UNPACKING & ASSEMBLY 1 - Boxed CPA in position. 1/3 panel being raised from crate 2 - CPA panel being lowered into Toaster 3 - CPA panels (6 x 1/3) Assembled at bottom of Toaster 15

DUNE Far Detector FIELD CAGE UNPACKING & ASSEMBLY FC Panel FC Removed from crate, being lowered into Toaster 16

DUNE Far Detector FIELD CAGE UNPACKING & ASSEMBLY FC Panel CPA Panel FC Panels are assembled to FC array inside Toaster 17

Work in the Toaster • Work in toaster very constrained due to cryo towers • Access is needed on both sides of APA/CPA during installation. • HV and APA Consortium need to define what work needs to be done in toaster after mechanical assembly. • Need fixtures for assembling APA and CPA into full height and then transfer to TCO beam • We don’t want to work with APA/CPA on TCO beam because it blocks access to the cryostat • Four Options for Toaster work considered 18

DUNE Far Detector APA assembly & Fixture Location – Option ‘A’ Toaster Wall APA Fixture TCO Bridge APA Panel Cryostat Structure Gantry Lift platform 2m sq 19

DUNE Far Detector APA assembly & Fixture Location – Option ‘B’ Toaster Wall APA Fixture TCO Bridge APA Panel Cryostat Structure Gantry Lift platform 2m sq 20

DUNE Far Detector APA assembly & Fixture Location – Option ‘C’ Cryo Towers removed providing greater space – APA Panel access scaffolding Toaster Wall Gantry TCO Bridge Cryostat APA Fixture Structure Fixed Platform Elevated 8 ft apart (4) at Each work station 21

DUNE Far Detector APA assembly & Fixture Location – Option ‘D’ Cryo Towers removed providing greater space – access scaffolding Cryostat and lift Structure APA Panel Toaster Wall Movable Man-Lift Gantry TCO Bridge Foot APA Fixture Bridge Movable Man-Lift Fixed Platform Elevated 8 ft apart (4) at Each work station Toaster Wall 22

DUNE Far Detector APA / CPA Installation into Cryostat Anode Panel Cathode Panel Assembly (APA) Assembly (CPA) 23

DUNE Far Detector Shuttle System APA / CPA Installation into Cryostat DSS System 24

DUNE Far Detector Completed Panel Transportation Completed Panels are shuttled to their proper row on the DSS and ferried into place inside the Cryostat CPA Panel APA Panel FC Panel 25

DUNE Far Detector [slide title here] Anode Panel Assembly (APA) Cathode Panel Assembly (CPA) Anode Panel Assembly (APA) North Remove option install FC to CPA on ped – FC / CPA install will be in toaster New sheets: 1 - In-toaster assembly (several sheets) Field Cage (FC) 2 – alternate position (on ped wall) for APA fixture 26

Recommend

More recommend