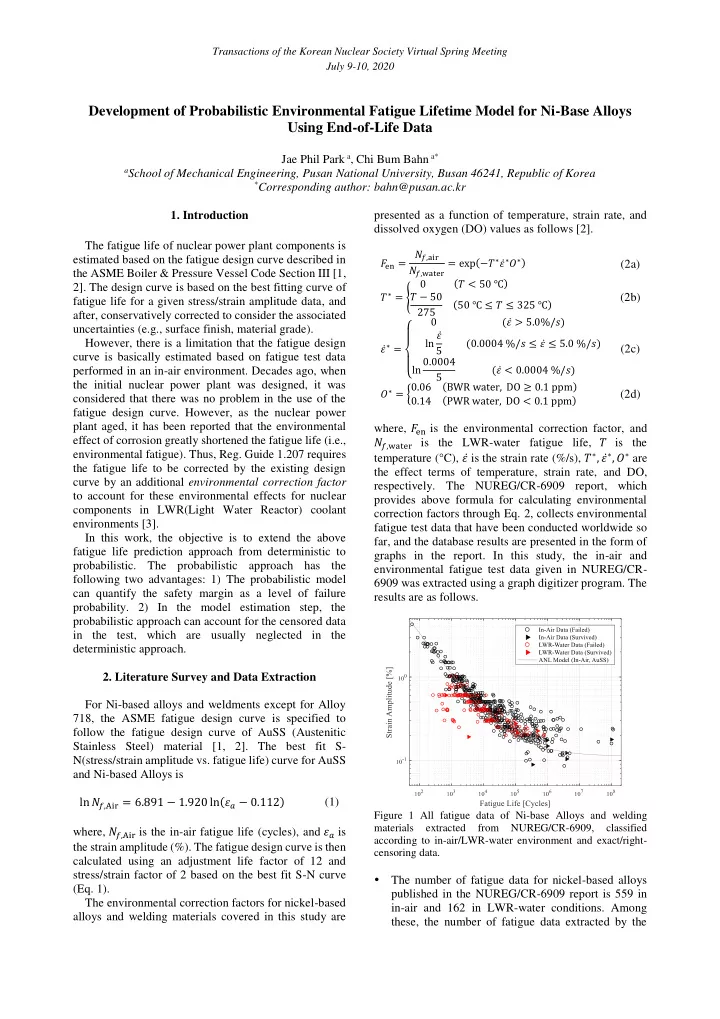

Transactions of the Korean Nuclear Society Virtual Spring Meeting July 9-10, 2020 Development of Probabilistic Environmental Fatigue Lifetime Model for Ni-Base Alloys Using End-of-Life Data Jae Phil Park a , Chi Bum Bahn a* a School of Mechanical Engineering, Pusan National University, Busan 46241, Republic of Korea * Corresponding author: bahn@pusan.ac.kr 1. Introduction presented as a function of temperature, strain rate, and dissolved oxygen (DO) values as follows [2]. The fatigue life of nuclear power plant components is 𝑂 estimated based on the fatigue design curve described in 𝑔,air = exp(−𝑈 ∗ 𝜁̇ ∗ 𝑃 ∗ ) 𝐺 en = (2a) 𝑂 the ASME Boiler & Pressure Vessel Code Section III [1, 𝑔,water 0 (𝑈 < 50 ℃) 2]. The design curve is based on the best fitting curve of 𝑈 ∗ = { 𝑈 − 50 (50 ℃ ≤ 𝑈 ≤ 325 ℃) (2b) fatigue life for a given stress/strain amplitude data, and 275 after, conservatively corrected to consider the associated 0 (𝜁̇ > 5.0%/𝑡) uncertainties (e.g., surface finish, material grade). ln 𝜁̇ However, there is a limitation that the fatigue design (0.0004 %/𝑡 ≤ 𝜁̇ ≤ 5.0 %/𝑡) 𝜁̇ ∗ = (2c) 5 curve is basically estimated based on fatigue test data ln 0.0004 (𝜁̇ < 0.0004 %/𝑡) performed in an in-air environment. Decades ago, when { 5 the initial nuclear power plant was designed, it was 𝑃 ∗ = {0.06 (BWR water, DO ≥ 0.1 ppm) (PWR water, DO < 0.1 ppm) (2d) considered that there was no problem in the use of the 0.14 fatigue design curve. However, as the nuclear power plant aged, it has been reported that the environmental where, 𝐺 en is the environmental correction factor, and effect of corrosion greatly shortened the fatigue life (i.e., 𝑂 𝑔,water is the LWR-water fatigue life, 𝑈 is the environmental fatigue). Thus, Reg. Guide 1.207 requires temperature (°C), 𝜁̇ is the strain rate (%/s), 𝑈 ∗ , 𝜁̇ ∗ , 𝑃 ∗ are the fatigue life to be corrected by the existing design the effect terms of temperature, strain rate, and DO, curve by an additional environmental correction factor respectively. The NUREG/CR-6909 report, which to account for these environmental effects for nuclear provides above formula for calculating environmental components in LWR(Light Water Reactor) coolant correction factors through Eq. 2, collects environmental environments [3]. fatigue test data that have been conducted worldwide so In this work, the objective is to extend the above far, and the database results are presented in the form of fatigue life prediction approach from deterministic to graphs in the report. In this study, the in-air and probabilistic. The probabilistic approach has the environmental fatigue test data given in NUREG/CR- following two advantages: 1) The probabilistic model 6909 was extracted using a graph digitizer program. The can quantify the safety margin as a level of failure results are as follows. probability. 2) In the model estimation step, the probabilistic approach can account for the censored data in the test, which are usually neglected in the deterministic approach. 2. Literature Survey and Data Extraction For Ni-based alloys and weldments except for Alloy 718, the ASME fatigue design curve is specified to follow the fatigue design curve of AuSS (Austenitic Stainless Steel) material [1, 2]. The best fit S- N(stress/strain amplitude vs. fatigue life) curve for AuSS and Ni-based Alloys is ln 𝑂 𝑔,Air = 6.891 − 1.920 ln(𝜁 𝑏 − 0.112) (1) Figure 1 All fatigue data of Ni-base Alloys and welding materials extracted from NUREG/CR-6909, classified where, 𝑂 𝑔,Air is the in-air fatigue life (cycles), and 𝜁 𝑏 is according to in-air/LWR-water environment and exact/right- the strain amplitude (%). The fatigue design curve is then censoring data. calculated using an adjustment life factor of 12 and stress/strain factor of 2 based on the best fit S-N curve The number of fatigue data for nickel-based alloys (Eq. 1). published in the NUREG/CR-6909 report is 559 in The environmental correction factors for nickel-based in-air and 162 in LWR-water conditions. Among alloys and welding materials covered in this study are these, the number of fatigue data extracted by the

Recommend

More recommend