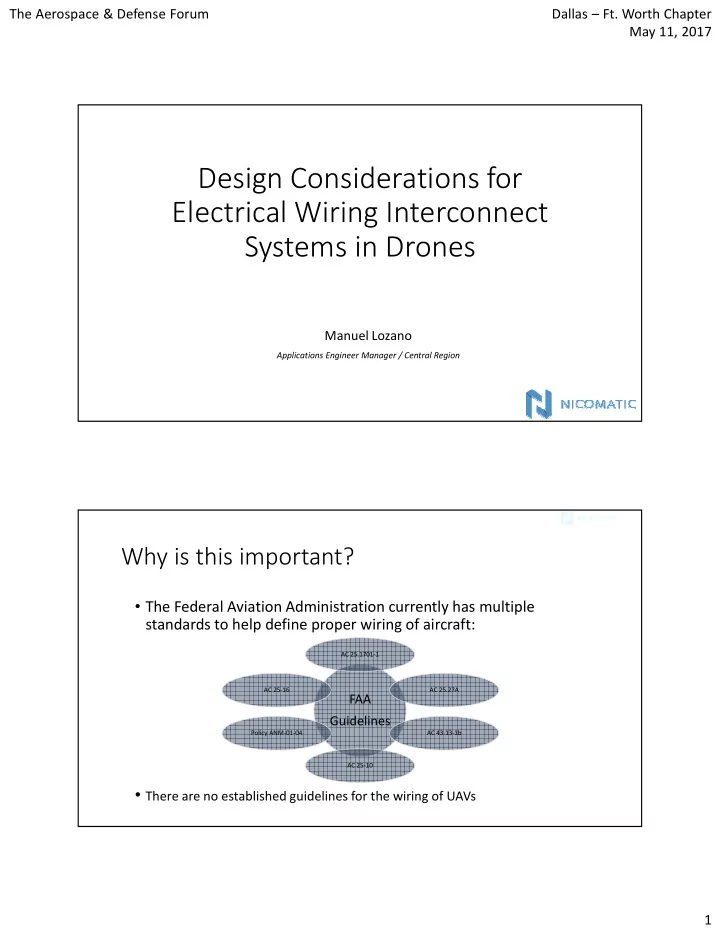

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Design Considerations for Electrical Wiring Interconnect Systems in Drones Manuel Lozano Applications Engineer Manager / Central Region Why is this important? • The Federal Aviation Administration currently has multiple standards to help define proper wiring of aircraft: AC 25.1701-1 AC 25-16 AC 25.27A FAA Guidelines Policy ANM-01-04 AC 43.13-1b AC 25-10 • There are no established guidelines for the wiring of UAVs 1

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Electrical Wiring Interconnection System • Federal Aviation Administration defines EWIS as: Any wire, wiring device, or combination of these, including termination devices, installed in any area of the airplane for the purpose of transmitting electrical energy between two or more intended termination points. Market size • More than 181,000 people have registered UAVs with the federal government since December 21 (9) • The FAA has approved more than 3,000 companies to use UAVs (9) • 4.3 million UAVs were sold worldwide in 2015 Figure 2 – (10) 2

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Market size – Section 333 • By law, any commercial aircraft operation in national airspace requires a certificated and registered aircraft, a licensed pilot, and operational approval • Section 333 of the FAA Modernization and Reform Act of 2012 (FMRA) grants the Secretary of Transportation the authority to determine whether an airworthiness certificate is required for a UAS to operate safely in the National Airspace System Market size – Section 333 • As of April 13, 2016, the FAA has approved more than 5,542 petitions for Section 333 exemption (16) (15) 3

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Statistics Military • More than 400 large military drones crashed between September 2001 and December 2013 (1) • Of those, 194 were Class A accidents • Destroyed aircraft or caused at least $2 million in damage • The number of military drone crashes is increasing • Consumer drone crashes is expected to follow the same pattern Figure 1 – (2) Related Industries United States Navy • United States Navy created the Wiring Systems Branch to research, test, and evaluate U.S. Navy aircraft electrical wiring systems • 3,045 U.S. Navy aircraft fly approximately 921,658 flight hours per year • U.S. Navy experiences approximately 1,446 maintenance events per year due to wiring systems (14) • From 1995 to 2002, there were 31 mishaps due to aircraft electrical wiring system failures • 6 Class A mishaps • Resulting total cost of damages of $1 million or more, a DoD aircraft is destroyed, or an injury results in fatality or permanent disability • 3 Class B mishaps • Resulting total cost of damages is between $200,000 and $1 million, an injury results in permanent partial disability, or when 3 or more personnel are hospitalized for inpatient care • 22 Class C mishaps • Resulting total cost of damages is between $20,000 and $200,000, a nonfatal injury that causes any loss of time from work beyond the or shift on which it occurred, or a nonfatal occupational illness that causes loss of time from work or disability at any time 4

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Related Industries United States Navy Figure 4 – Typical Wire System Failure Modes For U.S. Navy Aircraft (1980-1999) (13) Related Industries United States Air Force • 43 percent of aircraft mishaps related to electronics were due to the wiring interconnect system (17) Figure 3 – Electrical Components Contributing To Air Force Aircraft Mishaps (13) 5

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Related Industries Non-Military • Reported accidents: Date Location Event Injuries Reference May 2014 Vancouver Filming Commercial 0 3 April 25, 2014 Texas Police Training Exercise 0 4 April 7, 2014 Australia Triathlon 1 5 October 2, 2013 New York City Manhattan Street 0 7 August 24, 2013 Virginia Virginia Motorsports Park Multiple 8 August 20, 2013 Wyoming Wedding 1 9 Projected Statistics 5000000 14000000 [VALUE] [VALUE] 4500000 Registered Individuals Registered Individuals 12000000 4000000 1 Based on usage of 12 hours per year per UAV 10000000 3500000 Registered Companies Registered Companies 3000000 8000000 2 Based on usage of 48 hours per year per UAV 2500000 [VALUE] [VALUE] 6000000 Purchased UAVs Purchased UAVs 2000000 3 Based on usage of 3 hours per year per UAV [VALUE] 1500000 4000000 [VALUE] 1000000 2000000 500000 0 0 1 2 3 Market Size Projected Flight Hours 6

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Projected Statistics 25000 70 [VALUE [VALUE 14 [VALUE 4 Based on U.S. Navy’s ] ] ] average flight hours between maintenance events caused by wiring Registered Individuals 60 12 20000 5 Based on U.S. Navy’s average flight hours 50 10 between mishaps caused by wiring system failure Registered Companies (Occur every 208,116 hours of flight) 15000 40 8 [VALUE 6 Based on U.S. Navy’s [VALUE ] average flight hours 30 between Class A mishaps 6 Purchased UAVs ] [VALUE caused by wiring (Occur 10000 every 1,075,267 hours of ] [VALUE flight) [VALUE ] 20 4 [VALUE ] ] 5000 10 2 0 0 Number of Yearly Mishaps 5 0 Number of Yearly Fatalities Caused Caused by Wiring System Failure Number of Yearly Maintenance 4 6 by Wiring System Failures Events Caused by Wiring Projected Statistics 600 [VALUE ] Registered Individuals 500 7 Based on Air Force’s average flight hours between 400 Registered Companies Class A mishaps (Occur every 25,125 hours of flight) 300 [VALUE ] Purchased UAVs 200 [VALUE ] 100 0 Number of Yearly Mishaps 7 7

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Study Findings - Causes of EWIS degradation Vibration • Moisture • Federal Aviation Department of Heat • Contamination Administration Defense • Installation • Maintenance • Wiring 8

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Pre-Installation Design Considerations Receiving • Wire should be received from supplier on a spool • Conductors and shielding should be free of corrosion and/or broken strands • Insulation should not be damaged or cracked Pre-Installation Design Considerations Marking • Each wire should be marked with a part number • Used to identify wire and circuit relating to the wiring diagram • Marking can be printed on wire or on a tag which is attached to the wire 9

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Pre-Installation Design Considerations Mechanically Stripping Wire • Visually inspect the wire for any of the following conditions: • Nicked or cut strands • Frayed insulation • Un-stranded or bird cage strands • Over-twisted conductors after reshaping • Visually inspect the wire insulation for any damage including: • Crushed or cut by the tool • Deformation exceeding 20 percent of the insulation thickness • End of the insulation is not cut cleanly Installation Design Considerations Bending • The proper bend radius for wire on aircraft should be 10 times the outside diameter of the largest diameter wire in the bundle • If wire is supported on both ends, the bend radius can be 3 times the wire diameter 10

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Installation Design Considerations Chafing • Cables should not be riding on a structure or another wire bundle • Grommets should be installed around holes to prevent chafing • Use standoffs to maintain clearance between cables and structure • Tape and tubing is acceptable when clamps cannot be installed • Wire bundles • Properly installed riding on each grommet other Installation Design Considerations Clamping • Cables should have slack between clamps • Prevents strain at the terminal and reduces effects of stress caused by shock and vibration • Route cables perpendicular to clamps to prevent stress on the wires • Pinching of wires can be caused by improper installation or too many wires in a clamp 90° ±5° Sufficient slack should be provided between clamps 11

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Connectors Pre-Installation Design Considerations Visual Inspection • Be sure contacts are properly seated on both mating halves • Confirm that there are no bent contacts Contact is shorter than 2 bent contacts the others 12

The Aerospace & Defense Forum Dallas – Ft. Worth Chapter May 11, 2017 Installation Design Considerations Insufficient or Loose connectors lack of strain relief Focus Tight wire bends Worn seals Installation Design Considerations Loose Connectors • Be sure wire is not loose after being attached to the contact, either by crimping or soldering • Contacts should be secure when inserted into the connector housing • It is recommended that connectors be mated with a retention mechanism Latch Screw Acceptable Retention Mechanisms 13

Recommend

More recommend