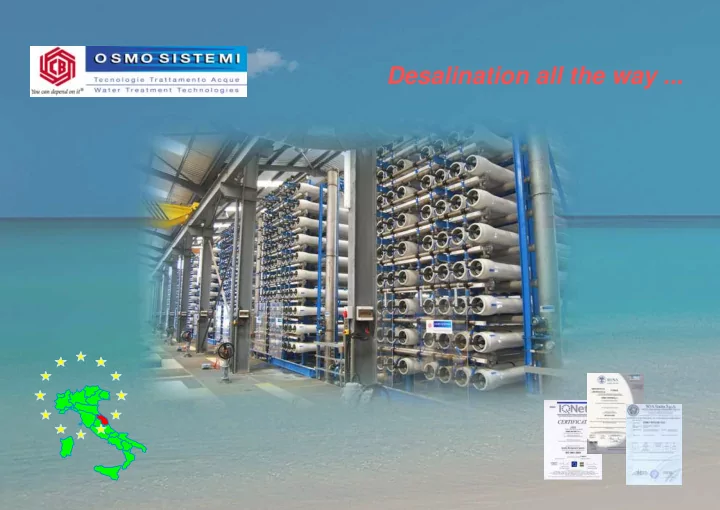

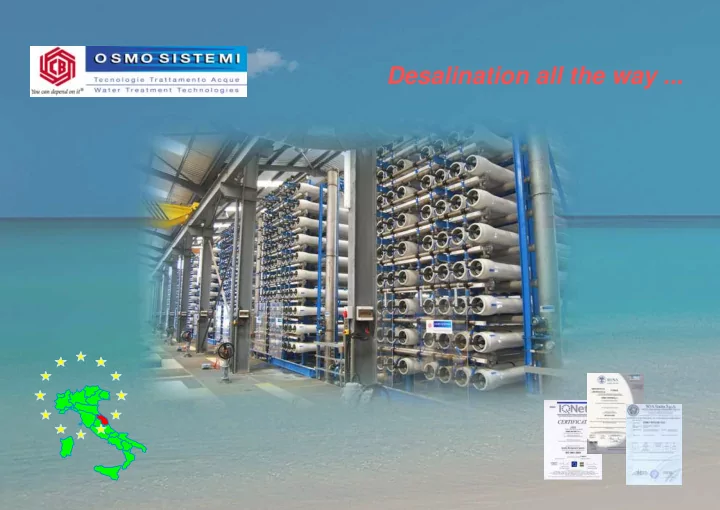

Desalination all the way ...

Company Profile Established in 1985, OSMO SISTEMI S.r.l., based in Italy, offers the services of a competent engineering team with extensive experience in the design, manufacture, installation, commissioning, start up, operation and maintenance of reverse osmosis and water treatment systems. OSMO SISTEMI S.r.l. is owned by CARAMONDANI DESALINATION PLANTS LTD (Cyprus) www.caramondani.com.cy The CARAMONDANI GROUP conducts its own activity in the mechanical, electrical engineering and desalination fields.

OSMO SISTEMI’s Products As a leader in primary, waste and industrial water treatment we design, manufacture and market: Sea Water Reverse Osmosis (SWRO) Plants Brackish Water Reverse Osmosis (BWRO) Plants Filtration Plants Softening Plants Denitrification Plants Grey water treatment plants CEDI, EDI, Demineralization Plants Iron, Manganese and Boron Removal Plants Micro Filtration, Ultra Filtration and Nano Filtration Plants

OSMO SISTEMI’s References PAST EXPERIENCES Flow rate 1 N of plants 1995 - 2005 (m³/day) 1.01 Plants for irrigation water 107 9.093 Plants producing drinking 1.02 water 109 32.568 Plants producing drinking 1.03 water on ships 6 9.643 Plants producing water for 1.04 industrial use 202 50.228 Plants producing water for 1.05 thermal power 33 3.199 TOTAL 457 104.730 RECENT EXPERIENCES Flow rate 2 N of plants 2006 – 2012 (m³/day) 2.01 Plants for irrigation water 43 3.746 Plants producing drinking 2.02 water 82 156.667 Plants producing water for 2.03 industrial use 162 16.666 Plants producing water for 2.04 thermal power 27 1.454 TOTAL 314 178.533

OSMO SISTEMI’s References BOOT, BOO, O&M Contracts RAW TYPE OF START COUNTRY PLACE m³/d PROCESS PURPOSE WATER CONTRACT END ITALY MONTERADO 240 BWRO WELL DRINKING O&M 1996-2001 ITALY CAVA DEI TIR. 3500 BWRO WELL DRINKING O&M 2000-2004 GELA ITALY (SICILIA) 1500 SWRO SEA INDUSTRIAL B.O.O. 2002-2003 LICATA ITALY (SICILIA) 1200 BWRO SURFACE IRRIGATION B.O.O.T. 2003 GELA ITALY (SICILIA) 250 SWRO SEA INDUSTRIAL B.O.O. 2004 TARANTO ITALY (PUGLIA) 1000 SWRO SEA INDUSTRIAL B.O.O. 2004 ITALY TARANTO 2X480 SWRO SEA INDUSTRIAL B.O.O. 2004-2010 GREECE HYDRA 500 SWRO SEA DRINKING B.O.O. 2007 CYPRUS DHEKELIA 60000 SWRO SEA DRINKING B.O.O.T.* 2007-2027 ITALY TARANTO 150 BWRO WELL DRINKING RENTAL 2008-2010 ITALY PESCARA 6000 BWRO WELL DRINKING O&M 2007-2008 ITALY FANO 2000 BWRO WELL DRINKING O&M 2008-2009 INDUSTRIAL JORDAN ALMAFRAQ 1100 BWRO WELL /DRINKING O&M 2009-2010 ROMANIA BUCHAREST 1000 BWRO MUNICIPAL INDUSTRIAL O&M 2009-2010 ( * ) By Caramondani Desalination Plants (mother company)

International References No. 1 Desalination Plant 68.000 m³/d Permeate water End User: O&M operator, Cyprus Sea Water R.O. plant No. 1 Permeate water R.O. Plant 20.000 m³/d Permeate water End User: O&M operator, Cyprus Permeate Water R.O. plant

International References Boron Removal Systems with Boron selective resin End User: O&M operator, Cyprus Energy recovery device in SWRO plant End User: O&M operator, Cyprus

International References No. 1 Plant of 10.500 m³/d Permeate water End User: Steel Industry, Iran River Water R.O. plant No. 1 Plant of 3.000 m³/d Permeate water End User: Municipality, Italy Brackish Water R.O. plant

International References No. 3 Plants of 1.200 m³/d Permeate water each End user: Touristic Village, Tunisia Brackish water R.O. plants No. 4 Plants of 1.200 m³/d Permeate water each End user: Chemical-Minerary Industry, Italy Sea water R.O. plants

SWRO Plants No. 1 Plant of 300 m³/d Permeate water End User: Municipality, Greece Sea Water R.O. plant No. 1 Plant of 250 m³/d Permeate water End User: Hotel Industry, Greece Sea Water R.O. plant

SWRO Plants No. 2 Plants of 1200 m³/d Permeate water each End User: Refinery, Italy Sea Water R.O. plants No. 2 Plants of 300 m³/d Permeate water each End User: Municipality, Greece Sea Water R.O. plants

Containerised SWRO Plants No. 1 Plant of 350 m³/d permeate Client: Hotel Industry, Capo Verde Sea water R.O. plant No. 2 Plants of 500 m³/d Permeate each End user: Municipality, Middle East Sea water water R.O. plant No. 1 Plant of 600 m³/d permeate Client: Refinery, Italy Sea water R.O. plant

Containerised BWRO Plants No. 1 Plant of 750 m³/d Permeate End user: Food Indusrty/Bottling Brackish water R.O. plant No. 2 Plants of total 1.500 m³/d Permeate End user: Food Indusrty, Jordan Brackish water R.O. plants No. 1 Plant of 1.200 m³/d permeate Client: Municipality, Italy Brackish water R.O. plant

High Capacity BWRO Plants No. 2 R.O. Plants 1.200 m³/d each End user: Steelworks – Turkey Brackish water R.O. plants No. 1 R.O. Plant 5.000 m³/d End user: Municipality, Italy Brackish water R.O. plant No.1 R.O. Plant 1.200 m³/d of permeate End user : Food Industry, Italy Brackish Water R.O. plant

OSMO Line Technical Characteristics Technical Characteristics - Mod.: OSMO AM 8 – 120 m³/h - Flow rate: - Power: 1-110 kW - Pressure: 18 bar - Dimensions: 750x160x192 cm 800 – 8.000 Kg - Weight:

OSMO Line Technical Characteristics Flow rate Power Recovery Tension Dimension Mod. m³/h kW % V cm OSMO 8 AM 8 11 50 - 75 400V/3+N/50Hz 500x130x172 OSMO 112 AM 120 2x45 50 - 75 400V/3+N/50Hz 750x220x220 *All capacities between 8 m³/h and 120 m³/h available as standard lines Standard Equipment - Stainless steel skid - Digital conductivity meter with - Inlet automatic isolating valve thermo-compensation of temperature - Safety pressure switches - Panel board complete with digital leds - Custom designed pretreatment system and mimic diagram - Antiscalant dosing set - Electrical panel and control system with - Multi-stage pump with three-phase electrical motor SIRIO microprocessor or PLC system - High pressure piping and valving in 316 L stainless - Visual displays showing flow rates, pressures and steel conductivity of product water - High permeating surface spiral wound R.O. - Integrated circuit of automatic flushing and chemical membranes - GRP pressure vessels cleaning of the R.O. membranes

BWRO Units – OSMO Line No. 1 R.O. Plant 3.000 m³/d End user: Municipality, Italy Brackish water R.O. plant No. 1 R.O. Plant 350 m³/d No. 1 R.O. Plant 1.200 m³/d End user: Bottling, Lybia End user: School, Kenya Brackish water R.O. plant Brackish water R.O. plant No. 1 R.O. Plant 400 m³/d End user: Bottling, Jordan Brackish water R.O. plant

BWRO Units – OSMO Line No. 2 R.O. Plants of total 6.000 m³/d End user: Municipality, Italy Brackish water R.O. plants No. 1 R.O. Plant 750 m³/d End User: Hotel Industry, Greece Brackish water R.O. plant No. 1 R.O. Plant 500 m³/d End user: Distillery, Italy Brackish water R.O. plant

Water Engineering Pumping Stations Pilot Plants Chemical Dosing Stations Filtration Plants

Grey water – sustainable building No. 1 UF Plant 8 m³/d End user: Civil house, Italy Grey water UF plant Example of sustainable building

OSMO SISTEMI S.r.l. VIA TONIOLO, 8/B – 61032 FANO ITALY TEL. +39.0721.855023 FAX. +39.0721.855005 website: www.osmosistemi.com Email: osmosistemi@osmosistemi.it

Recommend

More recommend