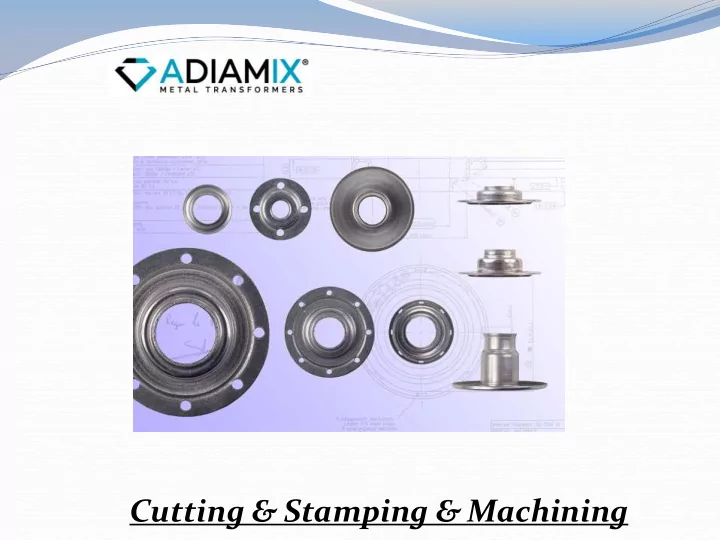

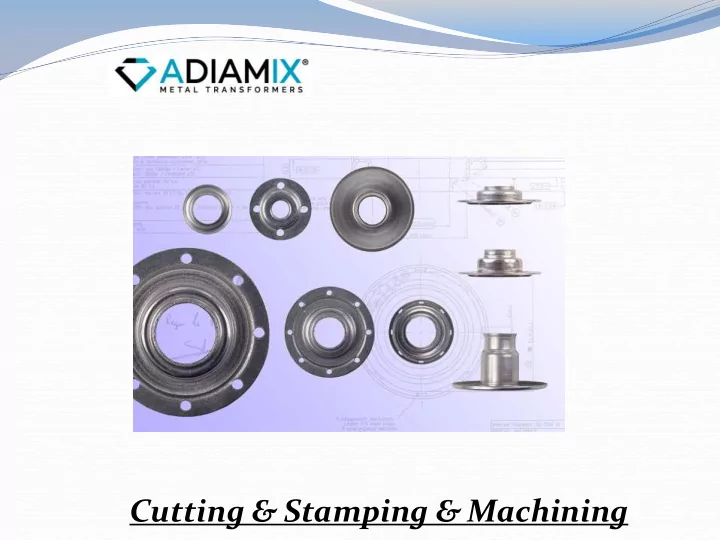

Cutting & Stamping & Machining

DIAM GROUP La Croix de l'Alizier 63500 PALLADUC - France + 33 (0)4 73 51 13 82 + 33 (0)4 73 51 13 83 www.diamgroup.com turnover 2016 : 12 M € turnover 2016: 11,2 M € 2 production plants in Normandy 1 production plant in Auvergne 80 persons 80 persons

2 production plants in Normandy, France (61) ADIAMIX LE SAP ADIAMIX ALENCON

Production plant: Production plant: 18-20 Rue du Chanvre à Tisser Les Terriers 61000 ALENCON 61470 LE SAP EN AUGE production workers 17 production workers 24 toolshop workers 11 Maintenance tool service 2 Employees administration/sales 10 Employees administration 11 production building 5000 m² Production building 5000 m²

Toolshop Cutting & stamping Machining Assembly & Degreasing & packaging cleaning ADIAMIX supplies cutting ADIAMIX supplies & stamping metal parts in machining parts in the range the range of medium to large of medium and large mass-production volumes productions for various for various sectors: sectors: Household Appliances, Electro mechanic, Automotive, Handling, Fluid Circulation, Agribusiness, Food Industry, Agriculture…

Sales turnover by market share

Reference customers electro mechanic

Parts references electro mechanic

References Customers Houshold appliances

Parts references Household appliances

References automotive

Parts references automotive

Parts references automotive

References customers general industries

Parts references general industries

1 500 t raw material a year Material Thickness: 0,15 mm – 2,5 mm Material width : 500 mm 50t 100t Alu Copper Stainless Steel Steel 650t Steel 700t Stainless Steel Copper Aluminium

E-Procurement system Stock management Purchasing Production orders ADONIX X3 Incoming orders Deliveries/Invoices customers

Engineering

Tool shop 2 CAD-Workstations (SolidWorks/LogoPress) 1 CNC milling machine 1 CNC lathe 2 Conventional milling machines 1 Jig boring machine 1 Wire electro-erosion machine 1 CNC electro-spark machine 7 Horizontal-grinding machines 1 Profile-grinding machine 2 Coordinate-grinding machines 1 3D measuring machine

In-house Prototyping

CNC lathe

Wire electro-erosion machine

Progression tool

Production means CUTTING & STAMPING 20 Standard automatic presses 80 t to 250 t 3 Fast automatic presses 40 t 4 Transfer presses 100 t to 400 t 2 Multiple ram presses (BIHLER) 2 Wire machines (LATOUR) 18 Excenter presses 50 t to 80 t

Presses 250t

Transfer press 400t

Degreasing machine

Vibration finishers

Machining of series production of foundry parts - Raw material: foundry, steel , aluminium… - Machining capacities: 300 * 300 * h=450 - Parts weight: until 10 kg - quantities: 15.000 à 100.000 parts / year 3 High-speed twin-spindle machining centers AXELOR 32

High-speed twin-spindle machining centers AXELOR 32J Automatic turning bridle system

References customers handling

Parts references handling

Machining of 700t raw parts of foundry a year

Assembly & packaging ADIAMIX offers assembly service of mechanical sets and subsets We can propose automatical, semi-automatic and manual solutions

Quality/Control - 1* Contour measuring station - MAHR - 2* 3D measuring machines - MITUTOYO ISO / TS 16949 in preparation

Thank you for your attention! www.adiamix.com

Recommend

More recommend