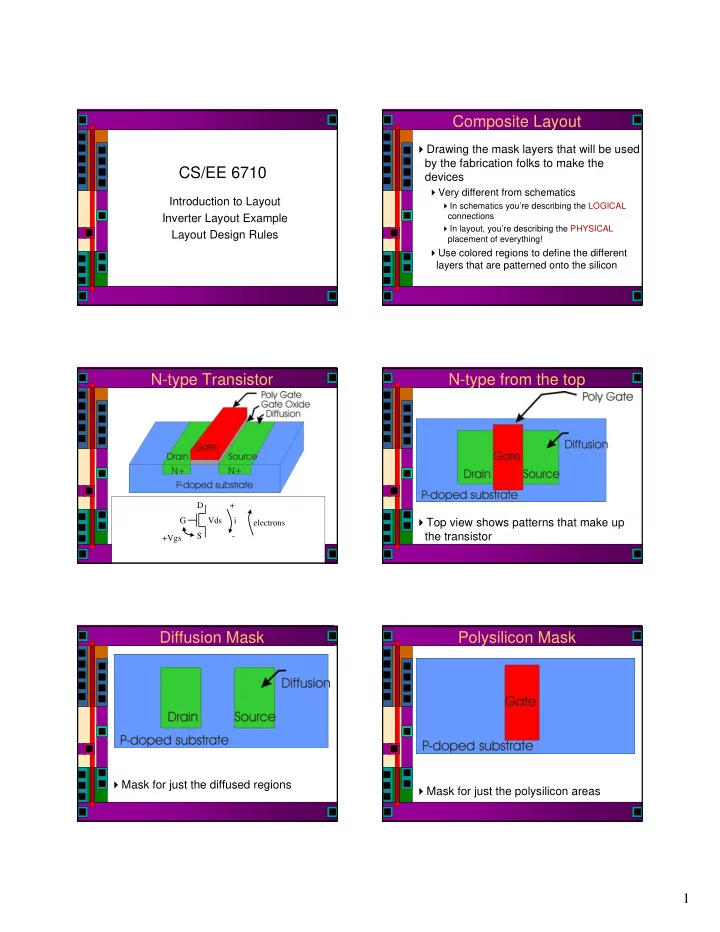

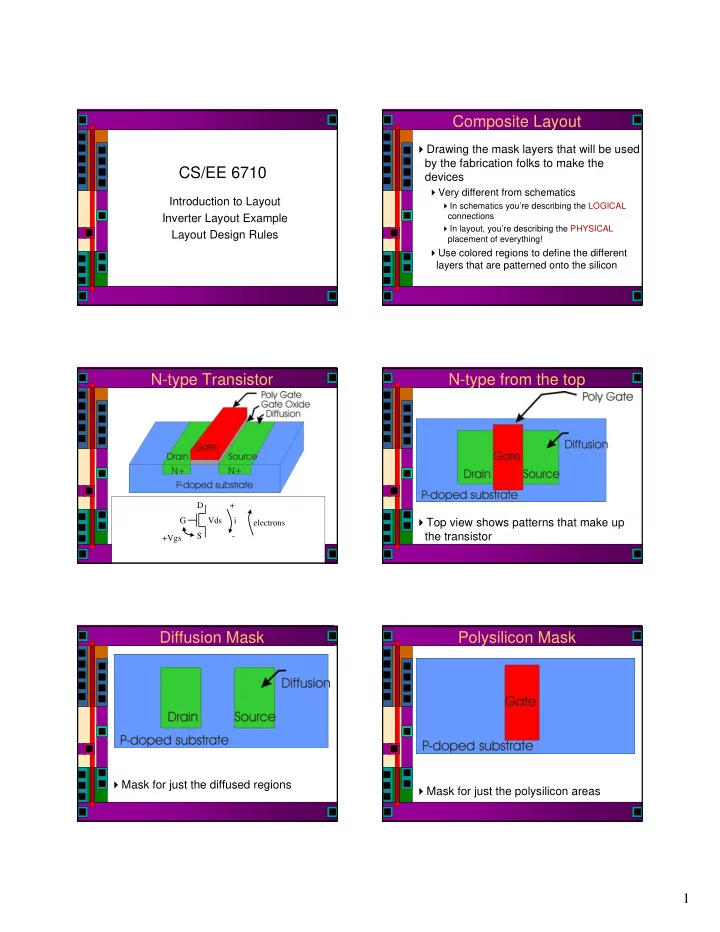

Composite Layout � Drawing the mask layers that will be used by the fabrication folks to make the CS/EE 6710 devices � Very different from schematics Introduction to Layout � In schematics you’re describing the LOGICAL connections Inverter Layout Example � In layout, you’re describing the PHYSICAL Layout Design Rules placement of everything! � Use colored regions to define the different layers that are patterned onto the silicon N-type Transistor N-type from the top D + G Vds i � Top view shows patterns that make up electrons the transistor S - +Vgs Diffusion Mask Polysilicon Mask � Mask for just the diffused regions � Mask for just the polysilicon areas 1

Combine the two masks P-type transistor � Same type of masks as the N-type � But, you have to get the substrate right � You get an N-type transistor � and you have to dope the diffusion � There are other steps in the process… differently General CMOS cross section Cutaway Photo � Note that the general substrate is P-type � The N-substrate for the P-transistor is in a “well” � There are lots of other layers � Thick SiO2 oxide (“field oxide) � Thin SiO2 oxide (gate oxide � Metal for interconnect A Cutaway View Top View from that Section � CMOS structure with both transistor types, and top-view structure � Note the different mask layers that correspond to the different transistor layers � In particular, note the N-well and P-select layers 2

This is an Inverter Layout in Cadence In Vdd Gnd Out � Each color corresponds to a mask layer � Draw rectangles to describe mask regions � A LOT of things to keep in mind � connectivity, functionality, design rules What are the layers? How do the Layers Interact? Photo of Interconnect Back to the Inverter � Let’s walk through drawing this inverter � You can draw layers in whatever order makes sense to you… 3

Layout Basics Layout Basics � Where poly crosses active = transistor � Diffusion, Poly, and metal all conduct � For N-type, nactive over the substrate (p � But resistances are very different substrate) � Diffusion is worst, poly isn’t too bad, metal is by � For P-type, pactive inside an Nwell far the best � Contact cuts are needed to connect � There’s really only one “active” mask between layers � nselect and pselect layers define active types � Make sure to use the right type of contact! � Our setup has separate nactive and pactive � Cc for poly-metal1, active-metal1 colors to help keep things straight. � Via1 for metal1-metal2 � Via2 for metal2-metal3 First Layout the Power Rails Now add Diffusion � Note the M1 contacts in the diffusion � Power rail pitch is important � Diffusion by itself will be N-type � Allows cells to connect by abutment � Diffusion in an N-well will be P-type � Also add the N-well for the P-type transistor � Or will it? The well just defines the substrate type Add the Select Regions Now add the Poly Gates � Remember: crossing diffusion with Poly makes � Nselect defines N-type diffusion a transistor � Pselect defines P-type diffusion � The type of the diffusion, and the type of well, define what kind of transistor 4

Note the Metal1 Connections Connect the Gates � Overlapping boxes of the same type of material � Connect gates together to form the inverter make a connection � Note contact cuts and metal overlaps � Overlaps of different types of material need a contact cut of some sort Layout Subtlety Well (or Substrate) Contacts � We currently think of transistors as three- terminal devices � Gate, Source, Drain � They’re really four-terminal devices � There’s also a connection to the substrate � It’s important to tie the substrate to a specific voltage � Connect P-substrate to GND (VSS) with a little � GND for the P-substrate stub of P-type diffusion (remember Pselect) � VDD for the N-well � Connect the N-well to VDD with a little stub of � Reasons later… Has to do with “latch up” N-type diffusion � I.e. inside the N-well, but with N-select Layout Design Rules Intra-Layer Rules (Lambda) � Define the allowed geometry of the Different Potential Same Potential different layers 18 3 0 Polysilicon � Guidelines for making safe process masks Well or 6 � Rules about the allowed sizes and shapes of 2 12 a particular layer 3 3 Metal1 Active � Rules about how different layers interact Contact or Via 2 3 � Dimensions listed in one of two ways 3 Hole 2 3 2 Metal2 � Absolute dimensions (I.e. microns) Select � Scalable dimensions in abstract units 3 2 � Usually called “lambda” 4 Metal3 Lambda = 0.50 => 1.0u process � Design in lambda units, then scale lambda for a Lambda = 0.30 => 0.6u process particular process 5 5

Intra-Layer Rules (Native) Transistor Layout Different Potential 0.6 Same Potential Measurements 5 0.6 0.6 0 are in microns Polysilicon Well or 0.3 based on scalable 5 5 0.6 rules and a lambda 0.3 0.8 0.6 of 0.3. Metal1 Active Contact or Via 0.5 0.9 0.8 0.6 Hole 0.6 1 0.7 0.5 Metal2 Poly 0.6 Select 1 0.7 0.9 Active 0.7 Dimensions are directly in microns Metal3 Some things scale uniformly, others don’t Select Native rules are generally more dense 0.8 Vias and Contacts Look at Inverter Layout Again 0.9 0.3 0.3 Via Metal to Poly Contact 0.3 Metal to 0.9 0 Active Contact 0.6 � Lots and lots of design rules to consider! � Use Design Rule Checking (DRC) to see if everything is OK Layout Design Rules SCMOS Nwell � On the class web page � Modified version of the MOSIS SCMOS Rev. 8 rules � Modified to show both Lambda and Micron dimensions � All our design will be done in microns � Because of the NCSU tech files � But, even though we’re using microns, we’re using the SCMOS Lambda rules… � Print them out in color if possible! 6

SCMOS Active (diffusion) SCMOS Poly SCMOS Select SCMOS Contacts SCMOS Contact to Poly SCMOS Contact to Active 7

SCMOS Metal1 SCMOS Via SCMOS Metal2 SCMOS Via2 SCMOS Metal3 8

Recommend

More recommend