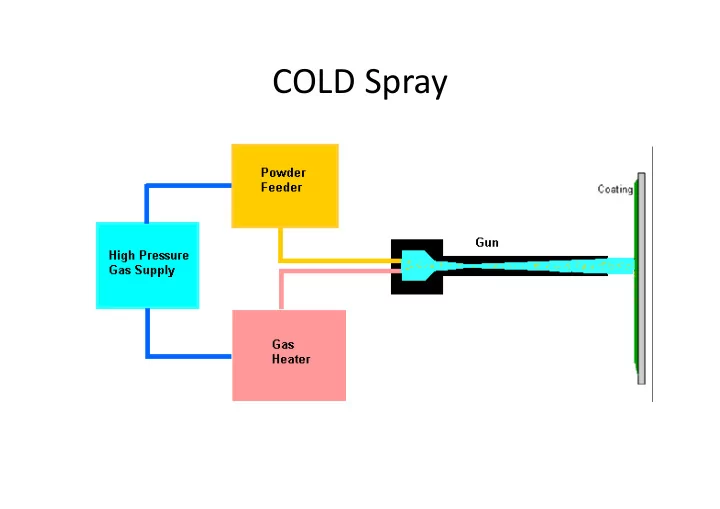

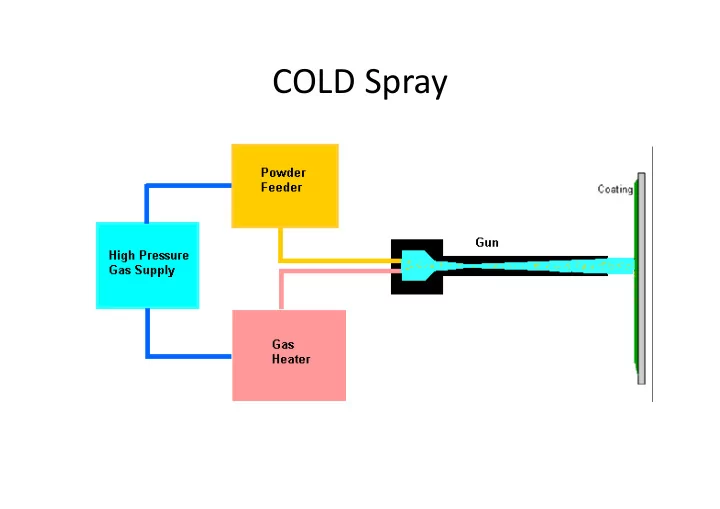

COLD Spray

POWDER REQUIREMENTS • Selection criteria: only the powders of materials that can deform plastically, can be sprayed by cold ‐ spray. • Ceramics and polymers cannot be applied by cold spray. Thus Metals and Alloys are the main choice. • – Face Centred Cubic (F.C.C.): structure metals, such as Al, Cu, Ag, Au, Pt, Ni, and γ‐ Fe Having large number of planes and thus can be deformed and are thus best for cold spray – Body Centred Cubic (B.C.C.): structure metals, such as W, Ta, Mo, Nb, V, Cr, α‐ Fe and β‐ Ti. – Hexagonal Close ‐ Packed (H.C.P.): structure metals, such as Cd, Zn, Co, Mg and Ti. The H.C.P. metals have lesser deformability, while the B.C.C. metals have the lowest • deformability. • M.P. is Another indication of sprayability. The low value of melting temperature is beneficial for the ability to spray. • On the other hand, materials that harden under mechanical stress, such as the stainless steel 316/304 or the alloy TiAl8V4, are difficult to spray. • In practice, the most popular material sprayed by cold ‐ spray is Cu. Important technological metal and alloys, such as Ta, NiCr, NiCrAlY or CuAl, have been • successfully processed by this technique . • Helium was used to spray most of these. Coating of metal ‐ ceramic composites, such as NiCr + Cr 3 C 2 , have also been obtained in this way . Particle size : 5 ‐ 20 μ m. • Particle temperatures and velocities: 500 o Cand particle velocities 600m/s for Cu particles • (15 μ m) with an optimized initial working gas (nitrogen).

Cold Spray Plasma Giken Kogyo co., ltd

Typical range of gas ‐ jet parameters for cold spray S.No Parameter Value 1 Stagnation jet pressure, 1 ‐ 3 MPa (psi) (145 ‐ 435) 2 Stagnation jet 0–700 temperature, °C Gas flow rate, m 3 /min ( 3 1–2 4 Powder feed rate, kg/h 2–8 5 Spray distance, mm 10–50 6 Power consumption, kW 5 ‐ 25 (for heating gas) 7 Particle size, μ m 1–50 8 Operating gases Air, N 2 , He, and their mixtures

Advantages Limitations • Low temperature process, no bulk particle • Hard brittle materials like ceramics can melting not be sprayed without using ductile binders • Retains composition/phases of initial particles • Not all substrate materials will accept coating • Very little oxidation High gas flows, high gas consumption. • • High hardness, cold worked microstructure • Helium very expensive unless recycled • Eliminates solidification stresses, enables • Still mainly in research and development thicker coatings stage, little coating performance/history data Low defect coatings • • Lower heat input to work piece reduces cooling requirement • Possible elimination of grit blast substrate preparation • No fuel gases or extreme electrical heating required • Reduce need for masking Main Uses •Improved Corrosion protection, performance •Improved Electrical and thermal conductivity. •No grain growth – good methods for nano powders.

MICROSTRUCTURES OF VARIOUS COATINGS Air Plasma HVOF Flame Spray

Comparison of various Thermally Sprayed Coatings

Comparison of various Thermal spray Processes

Flame Spray Process

Important Applications Room temperature Coatings on structures in highly aggressive environments. Highly hard coatings High Temperature Oxidation, sulphidation and hot corrosion resistant coatings

Machinery

Steel Industry

Consumer Goods High Temperature resistant Coating that can withstand heat during ironing

Probe Tube of a Fludized bed Reactor The probe (a) before the exposure and (b) after the 5900 h exposure in the biomass co ‐ fired boiler. On the left side the section with specimens at 550 C and on the right the specimens at 750 C

HVOF Coating for 550 ‐ 750 o C Optical micrographs of the coatings and the T92 reference material after the exposure at 550 C. (a) T92, (b) NiCr ‐ F_CJS, (c) IN65_DJ, and (d) NiCr ‐ C_DJ. EDX analyses of the corrosion scales of T92 (1, 2) are presented below the images [wt.%]

PROCES PARAMETERS OF CGDS AND HVOF IIT, BOMBAY Table. HVOF process parameters Table. Operating parameters of spray gun Sr.no. Parameter Values (HIPOJET-2700) 1 Carrier gas (N 2 ) 5 LPM Sr.no Gas Flow Operating pressure 2 Powder feed rate 36 g/min (LPM) kg/cm 3 1900 0 C 3 Average particle 1 Oxygen 350 10 temperature 2 LPG 70 7 4 Average particle velocity 300 m/s 3 Air 550 6 5 Standoff distance 30 cm MEC, Jodhpur 6 Deposition efficiency 40% Table. Cold spray process parameters sprayed with helium and nitrogen gases Parameter He processing N 2 processing Values Values ASB, Industries Gun temperature 400 0 C 450 0 C Ohio (US) Gun pressure 20 bars 38 bars Powder flow rate 18 g/min 15 g/min Carrier gas flow rate 3.0 m 3 /hr 3.0 m 3 /hr Number of passes 4 6

SUBSTRATE AND POWDER USED IIT, BOMBAY Table. Chemical composition of austenitic stainless steel (316L) (wt-%) Grade C Mn Si P S Cr Mo Ni N 316L 0.018 1.30 0.36 0.032 0.003 16.62 2.07 10.12 0.047 Table. As-received CoNiCrAlY powder Chemistry of powder Powder particle size Method of manufacturing Co32Ni21Cr8Al0.5Y 10-42 μ m Gas atomized Powder purchased from M/s. Metallizing Equipment Pvt. Ltd. Jodhpur, trade name MEC 9950 AMF Laser Diffraction Mean = 32.20 μ m Median = 32.63 μ m Fig. Powder morphology Fig. Plot of cumulative volume % vs particle diameter

PROPERTIES OF HVOF AND CGDS HE AND N 2 PROCESSED CoNiCrAlY SPRAYED DEPOSITION. Deposition properties He processing N 2 processing HVOF processing Thickness of coating 320-360 μ m 105-115 μ m 165-299 μ m Microstructural Dense and compact Pores and porosity Porosity and features coating visible defect 8.41 ± 0.55 Surfaces roughness 23.41 ± 1.30 16.04 ± 1 Values Ra (µm) Porosity level (%) 0.9 ± 0.8 5 ± 0.9 16 ± 0.9 Interface Mechanically bonded Interface between Shrinkage of the two particles and molten droplets, porosity present porosity and visible defect Extent of plastic High degree of Lower degree of High degree of deformation of plastic deformation plastic deformation plastic powder particles deformation and Shrinkage of the molten droplets

AS-SPRAYED CROSS-SECTION OF HVOF AND CGDSPRAYED WITH He ANDN 2 CARRIER GASES COATINGS IIT, BOMBAY Sr.no. He N2 Density 01785 1.250 (kg/m 3 ) Specific 1.660 at 1.404 at Heat ratio (20 0 C) (15 0 C) Fig. SEM images of CGDS and HVOF coatings in as-sprayed condition

EDX COMPOSITION AT CROSS-SECTION OF CGDS AND HVOF COATINGS IIT, BOMBAY Fig. SEM images and EDX compositions at cross-section of CGDS and HVOF coatings

SUMMARY IIT, BOMBAY Table. Summary of as-sprayed coatings Deposition properties CGDS He processing CGDS N 2 processing HVOF processing Thickness of coating 320-360 μ m 105-150 μ m 165-299 μ m Microstructural Dense and compact Pores and porosity Porosity and visible features coating defect Surfaces roughness 23.41 ± 1.30 16.04 ± 1 8.41 ± 0.55 Values Ra (um) Porosity level (%) 0.9 ± 0.8 5 ± 0.9 10 ± 0.9 Extent of plastic High degree of plastic Interface between two High degree of plastic deformation of deformation particles and porosity deformation and powder particles present due to Shrinkage of the insufficient plastic molten droplets deformation Hardness 6.60 6.35 5.04

KINETICS OF HVOF AND CGDS SPRAYED WITH He AND N 2 COATINGS IIT, BOMBAY The parabolic law the rate is • inversely proportional to the square root of time, is found to be obeyed when diffusion through the scale is the rate determining process Where Δ m = mass gain in g; • A= total surface area of the • Fig. Mass gain curve obtained during isothermal sample in cm 2 ; oxidation of the CGDS and HVOF coatings after the oxidation at 900 0 C for 1000 hrs K p = constant in g 2 /cm 4 s -1 ; • K p = 1.28x10 -8 g 2 /cm 4 s -1 ; for HVOF and t= time in s • K p = 0.510x10 -8 g 2 /cm 4 s -1 for CGDS He coating K p = 0.100x10 -8 g 2 /cm 4 s -1 for CGDS N 2 coating

OXIDATION STUDY SURFACE SCALE MORPHOLOGY OF THE HVOF COATING IIT, BOMBAY Fig. Oxide scale surface morphology of HVOF coating after the oxidation at 900 0 C for different exposure times Fig. Cross-section microstructure of HVOF coating after the oxidation at 900 0 C for different times

EDX analysis of the HVOF coating after the oxidation at 900 0 C for different times IIT, BOMBAY Fig.EDX analysis of the HVOF coating after the oxidation at 900 0 C for different times

EDX analysis of cross-section of the HVOF coating after the oxidation at 900 0 C for different times IIT, BOMBAY Fig.EDX analysis of cross-section of the HVOF coating after the oxidation at 900 0 C for different times

WEAR AND FRICTION BEHAVIOUR OF CoNiCrAlY POWDER IIT, BOMBAY Fig. Experimental setup for pin-on disc Table. Parameters for wear a studies Coatings Weight (N) Track diameter (mm) Velocity (m/s) Rpm Bare 316L 5,10,15 40,60,80 0.4 190,127,96 HVOF 5,10,15 40,60,80 0.4 190,127,96 CGDS He 5,10,15 40,60,80 0.4 190,127,96 CGDS with N 2 5,10,15 40,60,80 0.4 190,127,96 The coating samples were prepared in the form of square pin with a dimension of 10x10x1 mm and fixed into the square pin fixture having dimension 10x10x0.5 mm size

SECTION - I WEAR AND FRICTION OF AS-SPRAYED COATINGS AND BARE 316L STAINLESS STEEL IIT, BOMBAY Fig. Wear rate and coefficient of friction of 316 L SS and coatings

Recommend

More recommend