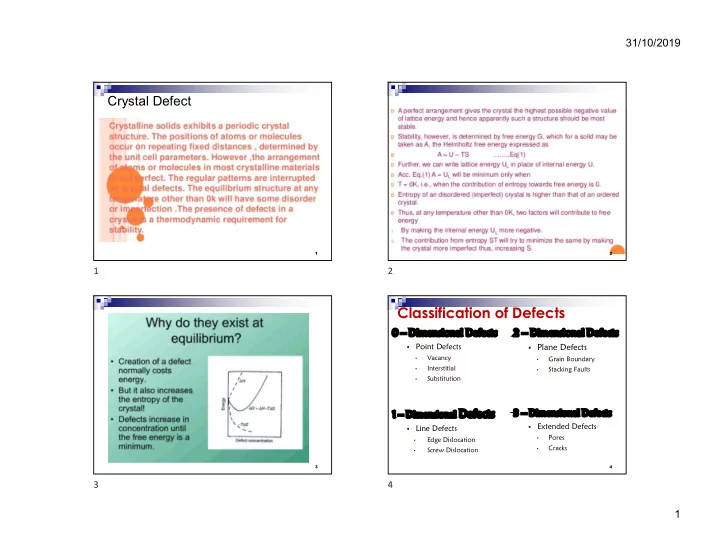

31/10/2019 Crystal Defect 1. Vector repositioned (if necessary) to pass through origin. 2. Read off projections in terms of unit cell dimensions a 1 , a 2 , a 3 , or c 3. Adjust to smallest integer values 4. Enclose in square brackets, no commas [ uvtw ] 1 2 1 2 Classification of Defects 0 – Dimensional Defects 2 – Dimensional Defects Point Defects Plane Defects Vacancy Grain Boundary • • Interstitial Stacking Faults • • Substitution • 1 – Dimensional Defects 3 – Dimensional Defects Extended Defects Line Defects Pores • Edge Dislocation • Cracks Screw Dislocation • • 3 4 3 4 1

31/10/2019 5 6 5 6 7 8 7 8 2

31/10/2019 9 10 9 10 11 12 11 12 3

31/10/2019 13 14 13 14 15 16 15 16 4

31/10/2019 17 18 17 18 19 20 19 20 5

31/10/2019 21 22 21 22 23 24 23 24 6

31/10/2019 25 26 25 26 27 28 27 28 7

31/10/2019 29 30 29 30 31 32 31 32 8

31/10/2019 33 34 33 34 35 36 35 36 9

31/10/2019 37 38 37 38 39 40 39 40 10

31/10/2019 41 42 41 42 43 44 43 44 11

31/10/2019 BURGERS VECTOR BURGERS VECTOR The magnitude and the direction of the displacement are defined by a vector, called the Burgers Vector . So, we have to move an extra step to return to P, in order to In figure (a), starting from the point P , we go up by 6 steps, then move close the Burgers circuit. towards right by 5 steps, move down by 6 steps and finally move towards left by 5 steps to reach the starting point P . the Burgers circuit The magnitude and the direction of the step defines the Burgers gets closed. Vector (BV). When the same operation is performed on the defect crystal (figure (b)) we end up at Q instead of the starting point. BV = = b QP The Burgers Vector is perpendicular to the edge dislocation line. 45 46 45 46 47 48 47 48 12

31/10/2019 49 50 49 50 51 52 51 52 13

31/10/2019 53 54 53 54 55 56 55 56 14

31/10/2019 57 58 57 58 59 60 59 60 15

31/10/2019 61 62 61 62 16

Recommend

More recommend