18 TH INTERNATIONAL CONFERENCE ON COMPOSITE MATERIALS CHARACTERISATIONS OF HYBRID COMPOSITES A. Kalam 1* ,M. N Berhan 1, ,H. Ismail 2 1 Fakulti Kejuruteraan Mekanikal, Universiti Teknologi MARA, Shah Alam Selangor, Malaysia, 2 School of Materials & Mineral Resources Eng., Universiti Sains Malaysia, Nibong Tebal. * Corresponding author (anizahkalam@salam.uitm.edu.my) Keywords : oil palm fruit bunch fiber, thermal degradation, water absorption, impact strength 1 Introduction were manufactured by Petronas Malaysia Bhd The addition of clay in oil palm fruit bunch (Malaysia). Maleic anhydride polypropylene (OPFB) fibre/PP composites [1] or also termed (MAPP) manufactured by Sigma Aldrich Inc. as hybrid composites showed an improvement (USA) was used as the coupling agent. The on its tensile and flexural moduli. However the mixtures of PPnanoclay/PP were consisted of thermal degradation and water absorption 10:100, 25:100, 40:100 and 100:100 by weight behaviors of the composites have not been ratio. Those mixtures were filled with 20 wt% investigated yet. Besides mechanical properties, of OPFB and 2 wt% of MAPP as coupling agent thermal degradation and water absorption to produce hybrid composites. The behaviors of the composites are important compounding was performed in a sigma blade thermal mixer at the temperature of 180 o C. The information needed during material selection. samples were prepared by using MCP vertical Clay presence in polymer composites was injection moulding to produce test samples proven to enhance its thermal degradation according to ASTM standard. behavior [2-4] which is strongly correlated with 2.2 Composite Characterizations reduced oxygen permeability resulting from an Thermal analyses were carried out using a elongated diffusion path. Meanwhile the effect Perkin Elmer Instruments thermo gravimetric of clay content on the water absorption behavior analyzer TGA. The tests were run in a nitrogen mainly contributed by the hydrophilic attributes atmosphere from room temperature to 800 o C of clay [5]. A study on the addition of clay in with a heating rate of 10 o C min -1 . Water-uptake wood fiber composites also found out [6] the measurements were performed by taking the increased in decomposition temperature and weight ( W i ) of all the specimens before being melting temperature of the hybrid composites. immersed in distilled water at room temperature of about 25 o C. At regular interval samples were This report will investigate the effect of clay weighed ( W t ) and prior to weighing the samples loading on the water absorption, thermal were carefully dried with soft cloth. The behaviour and impact strength of percentage of water uptake, M t was determined OPFB/PPnanoclay/PP hybrid composites. using the following equation: 2 Materials and Methods W W − t i 2.1 Materials and Sample Preparation M (%) 100 = × (1) t W i Oil palm fruit bunch (OPFB) fibres were pulverised and screened to the size of 250 - 180 3 Results and Discussion µ m. Polypropylene pellets with 10 wt% of clay 3.1 Thermal Degradation content (PPnanoclay) were supplied by Nanocor Inc (USA) meanwhile Polypropylene pellets

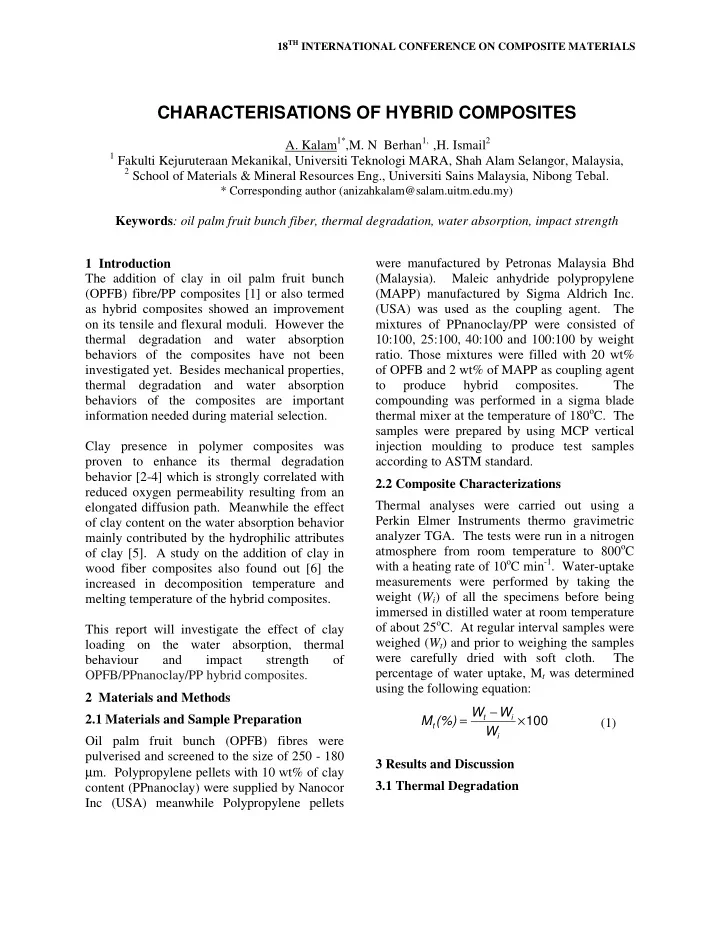

The thermal degradation behaviour of hybrid figure also indicates that the addition of composites with the increasing of PPnanoclay PPnanoclay has increased the water absorption loading is shown in Fig.1. The presence of 20 ability of composites, which can be related to wt% of OPFB in hybrid composites is indicated the hydrophilic nature of clay and OPFB fiber, by the first shoulder. There is no significant thus the higher clay content the higher water different in the number of shoulders in TGA absorption capability. Figure 3 shows the details curves of composites without and with of water absorption rate according to the PPnanoclay loading despite that they were number of day. Other factors contribute to the consist of different number of element. This is increase in water absorption capability such as believed due to the lower clay content in the microgaps and flaws at the interface between composites [2, 6, 7]. The decomposition fibres and matrix due to poor bonding [9]. temperature of hybrid composites has further 4.2 increased as the PPnanoclay loading increase, this trend is also agreed by other literature [2, 3.6 7]. 3.0 Water uptake (%) Ppnanoclay increase 2.4 100 1.8 80 1.2 0.6 Weight (%) 60 PPnanoclay 0.0 increase 0 50 100 150 200 40 Days 20 Fig. 2: The effects of PPnanoclay loading on the water absorption of hybrid composites. 0 0 200 400 600 800 o C) Temperature ( 4.1 Fig. 1: TGA results on the effect of PPnanoclay in hybrid composites. 3.6 Water uptake (%) The increase of decomposition temperature as 3.1 the PPnanoclay loading increase is believed due to the high aspect ratio of clay that act as heat 2.6 barrier, which could enhance the overall thermal stability of the system as well as assisting in the 2.1 formation of char after the thermal decomposition [8]. The char formation has also 1.6 increased with the increasing of PPnanoclay 30 50 100 150 180 loading. Days 0 phr 10 phr 25 phr 40 phr 100 phr 3.2 Water Absorption Behaviour Fig.3: Absorbed water according to the number The water absorption behaviour of hybrid of days. composites shown in Fig. 2 indicates water saturation was reached after 150 days. The

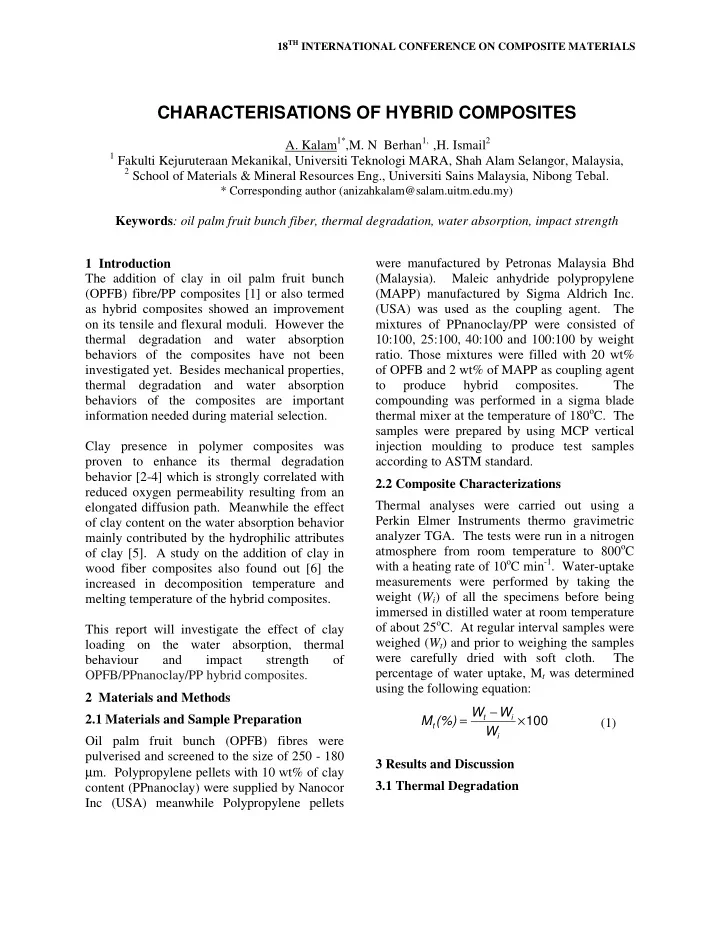

CHARACTERISATIONS OF HYBRID COMPOSITES 3.3 Impact Strength impact strength of hybrid composites showed in Fig.4, which indicates small increase (5%) with The effects of PPnanoclay loading on the impact the increasing of PPnanoclay loading from 10 to strength of hybrid composites are shown in 100 phr. Fig.4. The addition of PPnanoclay in the composite has slightly increased the impact strength and has further increased with the increasing of PPnanoclay loading between 8% - 13% at 10 phr to 100 phr PPnanoclay loading. The result suggests that the presence of clay has provided an alternative mechanism for energy dissipation in the hybrid composites. Several researchers [10, 11] believed that the increased in impact strength is an evidence of good interface bonding, however sometimes is not (a) true [12] because there are many factors affecting the impact strength especially in hybrid composites where the direction of crack growth continually changes as it encounters particles. Furthermore, the fibres that are randomly oriented introduce complex stress concentrations regions [12, 13] . 2.0 Impact Strength (kJ/m 2 ) 1.6 1.2 (b) 0.8 0.4 0.0 0 10 25 40 100 PPnanoclay loading (phr) Fig.4: Effect of PPnanoclay loading on the impact strength. 3.3 Impact Fracture Surface Fig. 5(a) and (b) show the fracture surfaces of (c) composites at 0, 10 and 100 phr of PPnanoclay loading respectively. Comparing micrograph in Fig.5: Impact fracture surface of composites at Fig. 5 (b) and (c) observed no significant (a) 0 phr, (b) 10 phr and (c) 100 phr of difference. This observation supported the PPnanoclay loading. result of the effect of PPnanoclay loading on the 3

Recommend

More recommend