BEEFMASTER II Joe Biggerstaff William Ryan Haar Matt Kilker - PowerPoint PPT Presentation

Custo tom m Agricul icultur tural al Solut lutions ions BEEFMASTER II Joe Biggerstaff William Ryan Haar Matt Kilker Taylor Miller Perfor Per ormanc mance e Engineer eered ed Custo tom m Agricul icultur tural al Solut

Custo tom m Agricul icultur tural al Solut lutions ions “BEEFMASTER II” Joe Biggerstaff William Ryan Haar Matt Kilker Taylor Miller Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions CAS Design Group Assignment Custom Agricultural Solutions (CAS) has been assigned with the task of improving the design of a manually operated cattle chute. Perfor Per ormanc mance e Engineer eered ed

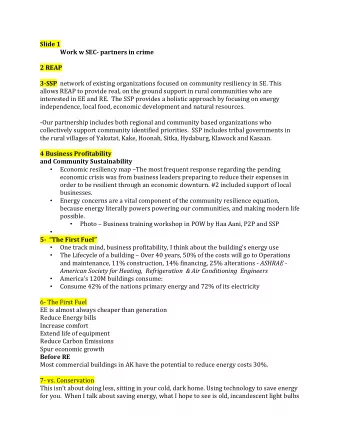

Custo tom m Agricul icultur tural al Solut lutions ions Overview Current Issues Testing and Operation Patent and Literature Research Design Criteria Concept Design Cost Analysis Future Plans Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Squeeze Mechanism Issues One Sided Squeeze Misalignment of Cattle One Sided Control Squeeze Emergency Exit Headgate Panels Centerline Centerline Reliability Noise Reduction Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Head Gate Issues Unreliable Latch Unable to Open Front Latch by Itself One Sided Control Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Tailgate Issues Operator Lifting Force Hanging Rope Noise Reduction Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Miscellaneous Issues Rumbar Floor Metal on Metal Contact Yoke Trailer Dimensions of Chute Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Testing and Observations Interviewed Ranchers Across Oklahoma Learned Customers Needs Operated Six Year Old Chute Analyzed Chute Size Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Patents Squeeze Head Catch Tailgate Breast Plate Breast Plate Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Literature Review Head Gate Forces Bovine Size Noise Solid Barriers (Restrict Vision) Optimal Pressure Non-slip Floor Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Design Criteria Fit In Powder Coater Maintain Saddled Pipe Practice Squeeze From Both Sides Maintain Emergency Exit Reduce Noise Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Head Gate Design Three Lever Double Latch Front, Back, and Combo Release Rubber Faced Stop Surface Swing Either Way Swing Rubber Backward Piece Swing Forward Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Head Gate Design Neck Access Panel Increased neck access Spring Solid Wall Loaded Latch (Vision Impairment) 9” Clearance Both Sides Removable Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Squeeze Mechanism Design Movement Safer Lever Position Inward and Forward Movement Rotating Proper Squeeze Placement Linkages 33’’ 7’’ Clearance Clearance Top Squeeze Lever Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Squeeze Mechanism Design Top Squeeze Self-Locking Easy Release Scissor Linkage Top Squeeze Locking Lever Notches Top Locking Squeeze Pin Release Per Perfor ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Squeeze Mechanism Design Bottom Squeeze Proven Parts Fold Down Lever Self Latching Cross-Over Bottom Cables Squeeze Release Bottom Squeeze Lever Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Squeeze Mechanism Design FEA Analysis of Critical Parts Stress Deflection Max Stress Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Tailgate Design Ease of Operation Multiple Tailgate Designs Simple Attachment Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Tailgate Design Scissor Gate Gravity Powered Self-Locking Proven Parts Cross-Over Cables Open/Close Handle Parallel Linkage Break Over Linkage Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Tailgate Design Guillotine/Slider Quickly Change Modes Multiple Applications User Friendly Slider Wheel & Track Guillotine Track Slider Handle Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Floor Design Noise Reduction No Slip Floor Easy Manufacturing Rumbar Cross Member Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Proposed Design Per Perfor ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Cost Analysis ITEM COST COMBINATION RETAIL VALUE (120% mark up) Basic Chute $1,600 Guillotine tailgate $74 $1,674 $3,683 Combo tailgate $222 $1,822 $4,007 Scissor tailgate $190 $1,789 $3,936 Existing Chute $1,386 $3,050 ITEM TOTAL # TOTAL COST Cuts 379 $95 Saddles 32 $8 Punches 138 $35 Welds 1531 $506 Total Labor Cost $643 Total Material Cost $536 Total Cost of WW Material $906 Total Cost of Prodotype $2,086 Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Future Plans Complete Manufacturing Documentation Produce Concept Test Concept Modifications Present Final Design Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Thank You Greg Overton, General Manager Pat Carhart, Sales Manager Don Lake, Applications Engineer Dr. Paul Weckler, Assistant Professor Dr. Glenn Brown, Professor Rolling R3 Ranch Perfor Per ormanc mance e Engineer eered ed

Custo tom m Agricul icultur tural al Solut lutions ions Questions? Per Perfor ormanc mance e Engineer eered ed

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.