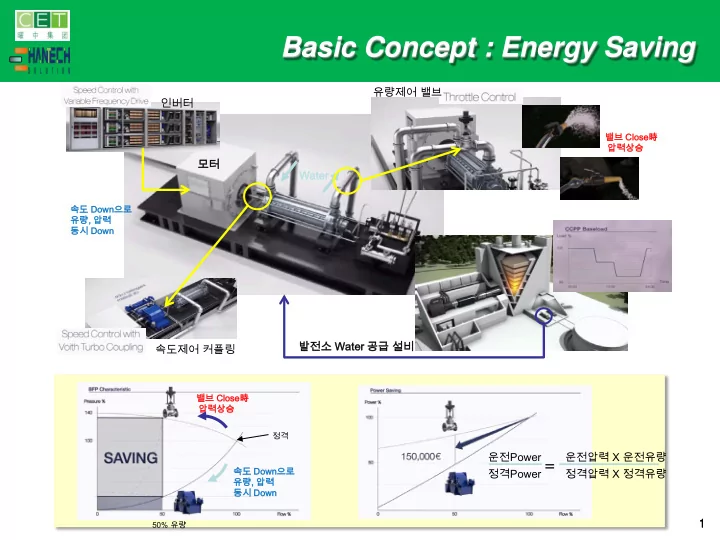

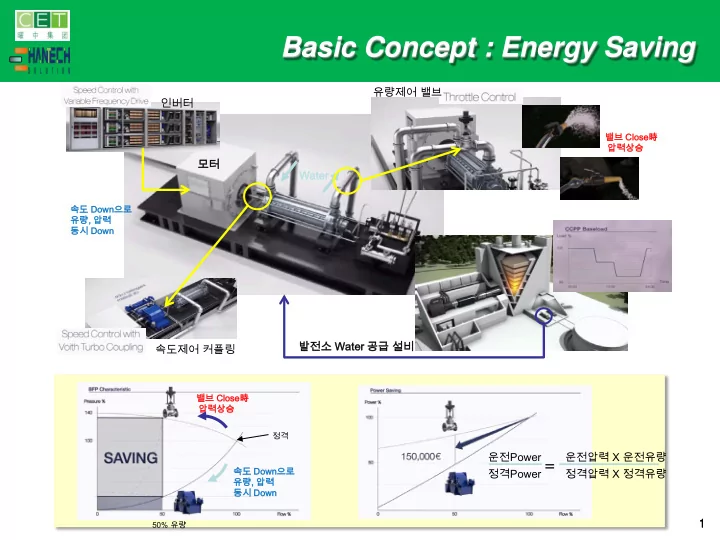

Basic Concept : Energy Saving 유량제어 밸브 인버터 밸브 Clo Close 時 압력상승 모터 Water ter 속도 Do Down wn 으로 유량 , 압력 동시 Do Down wn 발전소 Wat Water 공급 설비 속도제어 커플링 밸브 Clo Close 時 압력상승 정격 운전 Power 운전압력 X 운전유량 = 속도 Do Down wn 으로 정격 Power 정격압력 X 정격유량 유량 , 압력 동시 Do Down wn 1 1 50% 유량

Basic Concept : Simple 유체 Coupling 엑츄에이터 ( 유압제어 ) 팬 / 브로워 / 펌프 설비 운전속도 PLC / DCS 제어신호 (4~20mA) 압력 / 유량等 마그네틱 Coupling 제어신호 운전속도 팬 / 브로워 / 엑츄에이터 펌프 (Air Gap 제어 ) 설비 Simple : 설치 , 시운전 , 정비운영 2 2

Basic Concept : Magnet Coupling 3

TM MaxForce The Most Relia liable le Magne net A Adjus ustable Coup upling ng 4

TM MaxForce MAC Magnet Adjustable Coupling 5 5

MaxForce TM Benefits Imagine Operates While Misaligned Cushioned Start Cushions Shock Loads Controls Load Speed A Mechanical, Easy to Install Compact Disconnected Torque-transfer Technology Extends Equipment Life Reduces Vibration Eliminates Motor Seizure Easily Understood 6

MaxForce TM Values MaxForce TM Value Proposition MaxForce TM “Green” Disconnected Torque-transfer Technology reduces your total cost of ownership by lowering maintenance and operating costs, increasing process availability, and improving system reliability.” 7

MaxForce TM Values 8

TM MaxForce Art Of Technology - Air Gap Torque Transmitted Through Air Gap Eliminate Mechanical Connection Between Motor and Load Eddy Current Created on Conductor The Eddy Current Reflect Magnet Power and Torque Magnet Conductor Rotor Rotor Features - Tradition Coupling 涡流耦合器启动特性与节能 Start-up Current Feature MAC • Step Less Speed Control for Power Saving. • Simple and reliable Current • Cushion Start-up ( Reduce Impact Current ) • Over Load Protection, Protect Load Seizure • Electric Harmonic Free 9

TM MaxForce Core Patents in the World Patents For USA and PCT Matter Nos. Matter Titles Application Titles Application Nos. Filing dates Magnetic Coupler – 40087 Magnetic Coupler 61/507,097 12-Jul-11 Provisional App #1 Magnetic Coupler – 40087 Magnetic Coupler 61/584,913 Jan. 10, 2012 Provisional App #2 Magnetic Coupler – 40087 Magnetic Coupler 61/635,083 18-Apr-12 Provisional App #3 Magnetic Coupler – 40087.00001 Magnetic Coupler 61/664,589 26-Jun-12 Provisional App #4 Magnetic Coupler – 40087.00001 Magnetic Coupler 13/545,758 10-Jul-12 US App Magnetic Coupler – 40087.97001 Magnetic Coupler PCT/US2012/046296 11-Jul-12 PCT App 10

MAC Product Tree MAC Coupler Drive MAC-C MAC-D Traditional Coupler & VFD & Fluid Coupler Fluid Coupler 11

MAC Product Tree Horizontal Direct Mount Horizontal RPM Mount Vertical Mount Horizontal Liquid Cooled Vertical Liquid Cooled Fixed Gap Coupling Variable Gap Coupling High Performance Delayed Start-up Torque Limited 12

Typical Application Fan Pump Conveyor Other Cooling Tower 13

TM MaxForce Technology & Products 14

MAC-C (Coupling) 15

Coupling – Misalignment Misalignment Parallel / Offset Misalignment Axial Misalignment 16

Hydraulic Coupling – Issues Issue 1: Dirty Issue 3: Danger Issue 2: High Maintenance 17

MAC-C (Coupling) Air Gap Load Shaft Motor Shaft 18

MAC-C (Coupling) Coupling Benefits: • Offers Low Maintenance • Simple Installation • Efficient Torque Transfer • Permits Shock Loadings (Load is Cushioned & Slips) • Greater Misalignment Tolerance • Ideal for Applications Subject to: – Vibration – Periodic Load Seizure – Pulsating Loads – Thermal Expansion – Higher Starting Inertia/Torque 19

MAC-C for Pump Pump Application MAC-CV Replace Traditional Coupling Save 19% Energy 20

MAC-C for Blower ID Fan (560kW, 1200rpm) Application MAC-CV Replace Traditional Coupling Save 15% Energy 21

MAC-C for Conveyor After: MAC-CT400037 Before: Hydraulic Coupling Conveyor Application Use MAC-CT400037 , Replace Hydraulic Coupling Reduce Belt Impact, Load Seizure, Reduce Vibration, Free Maintenance & Power Saving 22

MAC-D (Drive) Magnet Rotor SAFET FETY Hubs and Shrink Discs RELI LIABLE LE ENERGY SA SAVING Air gap adjusting mechanism Conduct Rotor 23

MAC-D (Drive) Air Gap Conductor Motor Load Magnet 24

MAC-D (Drive) Magnet Adjustable Coupling/Drive • Variable Gap – For Adjustable Speed • Air-Cooled: – Sizes 20 to 500 Hp @ 1800 RPM – Horizontal & Vertical Applications • Oil-Cooled – 500 to 4,000 Hp @ 1800 RPM – Horizontal & Vertical Applications 25

MAC-D (Drive) MAC-D Benefits • Variable Speed Control • Up to 66% Energy Savings • Less System Maintenance • Accepts Greater Misalignment • Eliminates Vibration Transfer Between Motor & Load • Disengaged Startup • Permits Shock Loading • Increased Seal & Bearing Life • Eliminates Electronic Harmonics 26

Typical VFD Application Need Big Installation Space Need Air Conditioning Re-Loop High Voltage Power Cable New Motor for VFD Duty High-Specific Technician …. 27

Typical MAC-D Application Easy and Saving …. 28

29

MAC-D vs. VFD Customer Site Power Consummation Comparison Sheet Fan S peed Power Consummation w./ MAC-D Power Consummation w./ VFD Difference Input Input Input Input Input Power S peed Ratio Current Input Power Total Power (KVA) Voltage Voltage Current Power for AC 【 A 】 (KVA) 【 B 】 (KVA) 【 A-B 】 (rpm) (% ) (kv) (A) (V) (A) (KVA) (KVA) 900 51% 3.3 11.5 65.3 375.6 58.4 38.0 3.8 41.8 23.5 1000 56% 3.3 13.0 73.9 375.8 78.8 51.3 5.1 56.4 17.4 1100 62% 3.3 14.7 83.5 375.9 94.7 61.7 6.2 67.8 15.7 1200 67% 3.3 16.7 94.9 375.1 122.6 79.6 8.0 87.6 7.3 1300 73% 3.3 18.8 106.8 374.8 149.5 97.0 9.7 106.7 0.1 1400 79% 3.3 21.6 122.7 374.6 178.8 116.0 11.0 127.6 (4.9) 1500 84% 3.3 24.3 138.0 375.2 216.9 141.0 14.1 155.0 (17.0) 1600 90% 3.3 27.5 156.2 374.1 248.5 161.0 16.1 177.1 (20.9) 1700 96% 3.3 31.1 176.7 373.5 286.5 185.3 18.5 203.9 (27.2) 1740 98% 3.3 32.5 184.6 373.6 298.3 193.0 19.3 212.3 (27.7) 1. Due to the heat resulted from VFD operation, it needs 10% additional power consummation for air condition in control room. 2. Fan speed ratio >73%, MAC-D has better power saving. 30

MAC-D vs. VFD kVA 250 VFD MAC 200 150 100 50 0 58% 62% 66% 70% 74% 78% 82% 86% 90% 94% 98% 31

Typical MAC-D Application Steel Mining: Petrochemical Plant: Power Plant: 220KW ID Fan 280KW ID Fan 315KW Water Pump Energy Saving: 37% Energy Saving: 28% Energy Saving: 33% Over 560K Kw-Hr/Yr Over 550K Kw-Hr/Yr Over 720K Kw-Hr/Yr Saving RMB 280K/Yr Saving RMB 300K/Yr Saving RMB 300K/Yr 32

Recommend

More recommend