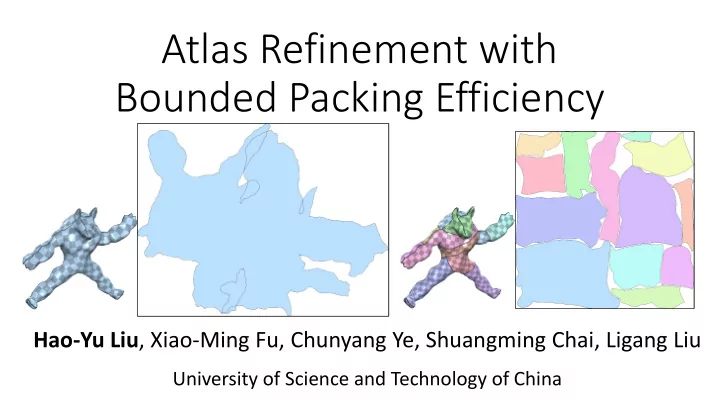

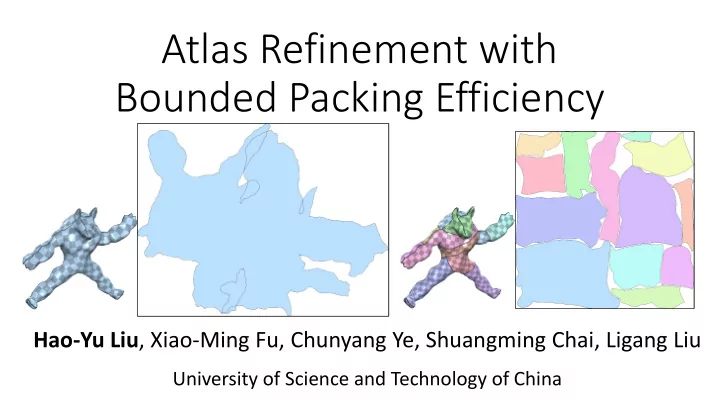

Atlas Refinement with Bounded Packing Efficiency Hao-Yu Liu , Xiao-Ming Fu, Chunyang Ye, Shuangming Chai, Ligang Liu University of Science and Technology of China

Atlas Normal Color

Texture

Packing Efficiency (PE) PE=86.1% PE=45.6% High pixel usage rate Low pixel usage rate PE=86.1%

Packing Efficiency (PE) Maximizing atlas packing efficiency is NP-hard! [Garey and Johnson 1979; Milenkovic 1999]

Other Requirements • Low distortion High Distortion Low Distortion

Other Requirements • Low distortion • [Golla et al. 2018; Liu et al. 2018; Shtengel et al. 2017; Zhu et al. 2018] • Consistent orientation • [Floater 2003; Tutte 1963; Claici et al. 2017; Hormann and Greiner 2000; Rabinovich et al. 2017; Schüller et al. 2013] • Bijection • [Jiang et al. 2017; Smith and Schaefer 2015] • Low boundary length • [Li et al. 2018; Poranne et al. 2017; Sorkine et al. 2002] These methods do not consider PE!

Atlas Refinement Input Bijective High PE

Previous Work Box Cutter [Limper et al. 2018] • Cut and repack No guarantee for a high PE result!

Motivation

Packing Problems ? Irregular shapes Rectangles Hard to achieve high PE Simple to achieve high PE Widely used in practice

Axis-Aligned Structure Axis-aligned structure Rectangle decomposition High PE (87.6%)!

General Cases Axis-aligned deformation Not axis-aligned Axis-aligned Higher distortion

Distortion Reduction Distortion reduction Scaffold-based method [Jiang et al. 2017] Bijective & High PE Axis-aligned Bijective & High PE High distortion High distortion Low distortion Bounded PE

Axis-aligned deformation Rectangle decomposition Pipeline and packing Distortion reduction

Axis-Aligned Deformation • Input Single chart 10 charts Not bijective Bijective

Axis-Aligned Deformation • Targets of boundary edges • Smoothing • Labeling • Deformation

Axis-Aligned Deformation Direction vector Fail! Ambiguous rotating directions

Axis-Aligned Deformation Polar angle Success! Clear rotating direction

Polar Angle 𝜄 = atan2(𝑧, 𝑦) + 2𝑙𝜌 (x,y) 𝑒𝜄 = 𝑦𝑒𝑧 − 𝑧𝑒𝑦 𝑦 2 + 𝑧 2

Polar Angle Discrete boundary curvature 𝜄 𝑗+1 = 𝜄 𝑗 + 𝜌 − 𝛽 𝑗 Gauss – Bonnet formula 𝜌 − 𝛽 𝑗 = 2𝜌 𝑗

Ƹ • Boundary smoothing Target Calculation • Gaussian smooth 2 𝑚 𝑘 exp − dist 𝑐 𝑗 , 𝑐 𝑙 = 𝑘 𝑙 𝐻 𝜏 s 𝑗 𝑡 𝑘 2𝜏 2 b 𝑘 𝑙 = 𝐻 𝜏 𝑙 ‖ 𝑙 𝑡 𝑗 𝑡 𝑗 ൗ ‖𝐻 𝜏 𝑡 𝑗 𝑙 if Ƹ 𝑙 ⋅ 𝑡 𝑗 𝑙 ≥ 0 • Accept Ƹ 𝑡 𝑗 𝑡 𝑗 • Update interior angles 𝑙+1 = ො 𝑙 + ∠ 𝑡 𝑗 𝑙+1 − ∠ 𝑡 𝑗+1 𝑙 , 𝑡 𝑗+1 𝑙 , 𝑡 𝑗 𝑙+1 𝛽 𝑗 ො 𝛽 𝑗 • Global rotation • Polar angle axis-alignment

Axis-Aligned Deformation Target polar angle 𝛪 𝑗 Corners

Axis-Aligned Deformation • Energy of boundary alignment Rotate polar angle Keep length 2 2 𝐹edge 𝐜 𝑗 = 1 2 (1 − 𝛿) 𝜄 𝑗 − 𝜌 + 1 𝑚 𝑗 2 𝛪 𝑗 2 𝛿 0 − 1 𝑚 𝑗 𝑂 𝑐 0 𝑚 𝑗 𝐹align(𝐝) = 𝑚 0 𝐹edge 𝐜 𝑗 𝑗=1

Axis-Aligned Deformation • Energy of isometric distortion(symmetric Dirichlet) 𝐹d(c) = 1 Area f 𝑗 2 + ‖𝐾 𝑗 −1 ‖ 𝐺 2 4 ‖𝐾 𝑗 ‖ 𝐺 Area Mc f i ∈ Fc Keep low distortion and orientation consistency.

Axis-Aligned Deformation 0.2X Playback min 𝐹d(c) + 𝜇𝐹align(c) c s.t. det 𝐾 𝑗 > 0, ∀𝑗

Rectangle Decomposition and Packing The faces are all rectangles. But the number is too many.

Rectangle Decomposition and Packing • Motorcycle graph algorithm Score = PE − 𝜕 BL 1 /BL 0 PE 87.0% 83.6% 84.4% Score 0.688 0.659 0.658

Distortion Reduction Isometric energy min 𝐹reduction = 𝐹d(C) + 𝐹PE(C) C Barrier function s.t. 𝛸 is bijective of PE bound Scaffold-based method [Jiang et al. 2017]

Distortion reduction

Experiments

PE Bound Input PE=80% PE=85% PE=90% E d =1.039 E d =1.037 E d =1.041 E d =1.049

Collection of Models Input PE=80% E d =1.022 E d =1.026

Comparison to Box Cutter [Limper et al. 2018] Box Cutter Ours Input PE=81.1% PE=88.9% #F=4,656 E d =1.149 E d =1.087 179.8s 1.69s

Comparison to Box Cutter [Limper et al. 2018] Box Cutter Ours Input PE=75.8% PE=91.3% #F=100,000 E d =1.114 E d =1.066 247.8s 43.84s

Benchmark (5,588) PE=86.7% PE=86.2% E d =1.024 E d =1.020

Benchmark (5,588) PE=91.0% E d =1.001 PE=90.5% E d =1.011

Texture PE=80.4% PE=92.6% E d =1.119 E d =1.018

Single-source Geodesics [Prada et al. 2018] PE=89.1% E d =1.041

Conclusion

Conclusions • Our method provides a novel technique to refine input atlases with bounded packing efficiency. • Key idea: converting polygon packing problems to a rectangle packing problems • High and bounded packing efficiency • Good performance and quality • Practical robustness

Limitation & Future Work • Modification of the input atlas may not meet the original intention. • Boundary length elongation is not explicitly bounded. • There is no theoretical guarantee, especially for the axis-aligned deformation process.

Thank you!

Recommend

More recommend