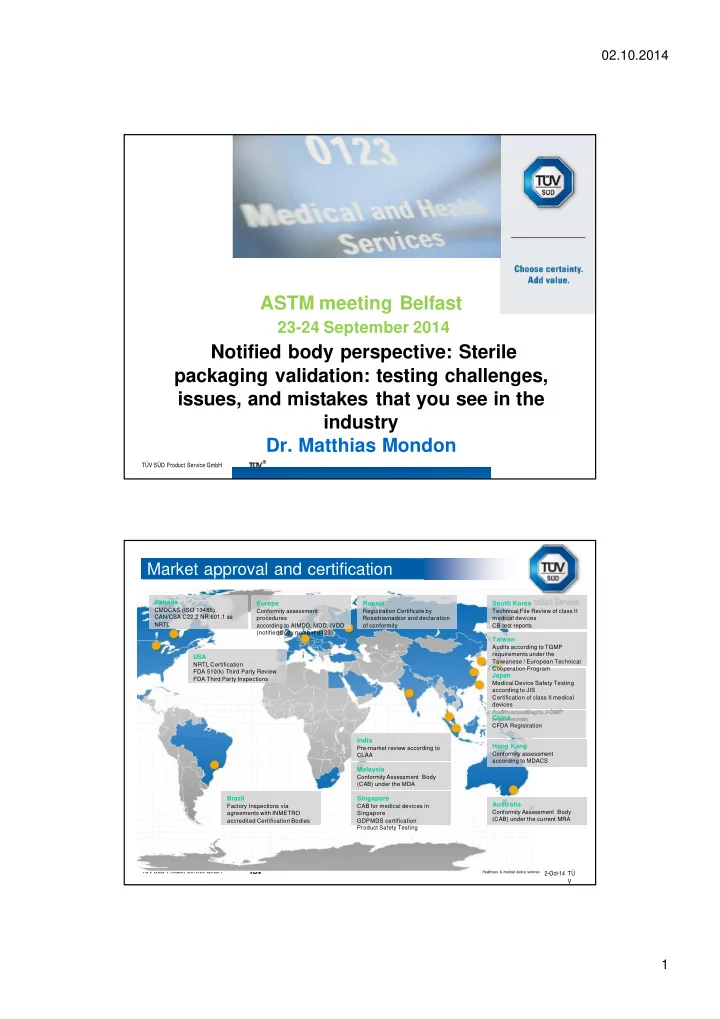

02.10.2014 ASTM meeting Belfast 23-24 September 2014 Notified body perspective: Sterile packaging validation: testing challenges, issues, and mistakes that you see in the industry Dr. Matthias Mondon TÜV SÜD Product Service GmbH Market approval and certification Canada Europe Russia South Korea CMDCAS (ISO 13485) Conformity assessment Registration Certificate by Technical File Review of class II CAN/CSA C22.2 NR.601.1 as procedures Roszdravnadzor and declaration medical devices NRTL according to AIMDD, MDD, IVDD of conformity CB test reports (notified body number 0123) Taiwan Audits according to TGMP requirements under the USA Taiwanese / European Technical NRTL Certification Cooperation Program FDA 510(k) Third Party Review Japan FDA Third Party Inspections Medical Device Safety Testing according to JIS Certification of class II medical devices Audits according to J-GMP China requirements CFDA Registration India Hong Kong Pre-market review according to Conformity assessment CLAA according to MDACS Malaysia Conformity Assessment Body (CAB) under the MDA Brazil Singapore Australia Factory Inspections via CAB for medical devices in Conformity Assessment Body agreements with INMETRO Singapore (CAB) under the current MRA accredited Certification Bodies GDPMDS certification Product Safety Testing TÜV SÜD Product Service GmbH Healthcare & medical device services 2-Oct-14 TÜ V 1

02.10.2014 TÜV SÜD in numbers: Growing from strength to strength 1 One-stop technical solution provider 150 years of experience 800 locations worldwide 1,900 million Euro in sales revenue 2013 20,190 employees worldwide TÜV SÜD Product Service GmbH Healthcare & medical device services 2-Oct-14 TÜ TÜV SÜD Product Services V SÜ Our heritage: 148 years of business success 1866 Establishment of a Mannheim-based steam boiler inspection association by 21 operators and owners of steam boilers, with the objective of protecting man, the environment and property against the risk emanating from a new and largely unknown form of technology 1910 First vehicle periodic technical inspection (PTI) 1926 Introduction of the “TÜV mark / stamp” in Germany 1958 Development of a Bavaria-wide network of vehicle inspection centres in the late 1950s Conglomeration of TÜVs from the southern part of 1990s Germany to form TÜV SÜD and the expansion of business operations into Asia Expansion of services in ASEAN by acquiring 2006 Singapore-based PSB Group 2009 Launch of Turkey-wide vehicle inspection by TÜVTURK Today TÜV SÜD pursues a strategy of internationalisation and growth TÜV SÜD Product Service GmbH Healthcare & medical device services 2-Oct-14 2

02.10.2014 Auditing and system certification services A selection of our auditing services Quality management For market access § ISO 13485 § Europe: MDD § ISO 9001 93/42 § ISO 15378 § U.S.: 21 CFR 820 § Japan: J-GMP § Canada: CMDCAS Risk management system § ISO 14971 § Taiwan: Taiwan GMP Health care providers / hospitals § Good Dialysis Practice § DIN EN 15224 Environmental § ISO 14001 TÜV SÜD Product Service GmbH Healthcare & medical device services 2-Oct-14 TÜ V Our asset. Your advantage. TÜV SÜD: A brand synonymous with quality and safety. Our certification marks and certificates are excellent marketing tools for our customers. Our test reports provide customers with the confidence to market their products’ safety, quality and sustainability attributes. > 320,000 product > 46,000 system certificates certificates TÜV SÜD Product Service GmbH Healthcare & medical device services 2-Oct-14 TÜ V 3

02.10.2014 ASTM meeting Belfast 23-24 September 2014 Notified body perspective: Sterile packaging validation: testing challenges, issues, and mistakes that you see in the industry Dr. Matthias Mondon TÜV SÜD Product Service GmbH Why Packaging validation? Ever bought Bananas? Is something missing? Yes correct, the Packaging! TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 8 4

02.10.2014 Why Packaging validation? Is this all? We will get back to it TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 9 Why Packaging validation? Medical Device 93/42 EEC Also, medical devices must be packed safely! Where does that requirement come from? EC-Directive 93/42/EEC for Medical Devices TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 10 5

02.10.2014 Why Conformity? Medical device 93/42 EEC Annex e.g. II, V 93/42 EEC Article 3: Medical devices, must meet the essential requirements (MDD Annex I). 93/42 EEC Article 11: Compliance to Essential Requiremnts (MDD Annex I) must be demonstrated by a Conformity Assessment Procedure (e.G. Annex II.3). TÜV SÜD Product Service GmbH Contents Introduction MDD Requirements • Regulatory Requirements • Usability Standard Requirements ISO 11607 Documentation • Definition of the Typical failures in packaging Problems arising validation • Validated Methods from packaging procedures • Typical Test methods processes and Sampling size • Worst Case Definition TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 12 6

02.10.2014 Regulatory Requirements of the MDD Directive 93/42/EEC (MDD) Essential Requirements : • 3) The devices must achieve the performances intended by the manufacturer and be designed, manufactured and packaged in such a way that they are suitable for one or more of the functions referred to in Article 1 (2) (a), as specified by the manufacturer. . 5) The devices must be designed, manufactured and packed in such a • way that their characteristics and performances during their intended use will not be adversely affected during transport and storage taking account of the instructions and information provided by the manufacturer. TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 13 Regulatory Requirements of the MDD Directive 93/42/EEC (MDD) Essential Requirements : • 7.2) The devices must be designed, manufactured and packed in such a way as to minimize the risk posed by contaminants and residues to the persons involved in the transport, storage and use of the devices and to the patients… • 8.3) Devices delivered in a sterile state must be designed, manufactured and packed in a non-reusable pack and/or according to appropriate procedures to ensure that they are sterile when placed on the market and remain sterile, under the storage and transport conditions laid down, until the protective packaging is damaged or opened. • 8.1) The design must allow easy handling and, where necessary, minimize contamination of the device by the patient or vice versa during use TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 14 7

02.10.2014 Regulatory Requirements of the MDD Directive 93/42/EEC (MDD) Essential Requirements : • 8.4) Devices delivered in a sterile state must have been manufactured and sterilized by an appropriate, validated method (8.4) TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 15 Validation Requirements according to 7.5.2 of EN ISO 13485:2003 • The organization shall validate any processes for production and service provision where the output cannot be verified by subsequent monitoring or measurement. • http://www.imdrf.org/docs/ghtf/final/sg3/technical-docs/ghtf- sg3-n99-10-2004-qms-process-guidance-04010.pdf • (previously GHTF) TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 16 8

02.10.2014 Packaging Validation • Harmonized standard for packaging validation: – EN ISO 11607-1 – EN ISO 11607-2 • Harmonised standards refering to packaging validation – EN ISO 13485 Quality Management System – EN ISO 14937 Sterilization of medical devices – EN ISO 17664 reprocessing of medical devices EN ISO 17664 3.9 3.11 EN ISO 14937 E.4.3 TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 17 Responsibility for purchased Items What do I do if What do I do if the package is prefabricated? • The requirements on materials referenced shall apply to those used in preformed sterile barrier systems, as well as sterile barrier systems (Are the pre-shaped sealing-seams appropriate and compatible with the own production process and the own storage conditions?) Prefabricated packages are not assessed and documented ISO 11607-1:2009 5.1.1 TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 18 9

02.10.2014 Contents Introduction MDD Requirements • Regulatory Requirements • Usability Standard Requirements ISO 11607 Documentation • Definition of the Typical failures in packaging Problems arising validation • Validated Methods from packaging procedures • Typical Test methods processes and Sampling size • Worst Case Definition TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 19 Misleading labeling Does the packaging labeling show the real content? How will this product be aseptically presented? There are 4 possibilities to attach the label to indicate the information on the content. MDD Annex I 8.1, ISO 11607-1:2009 5.1.9; 6.2.2 TÜV SÜD Product Service GmbH Dr. Jan Havel 02.10.2014 20 10

Recommend

More recommend