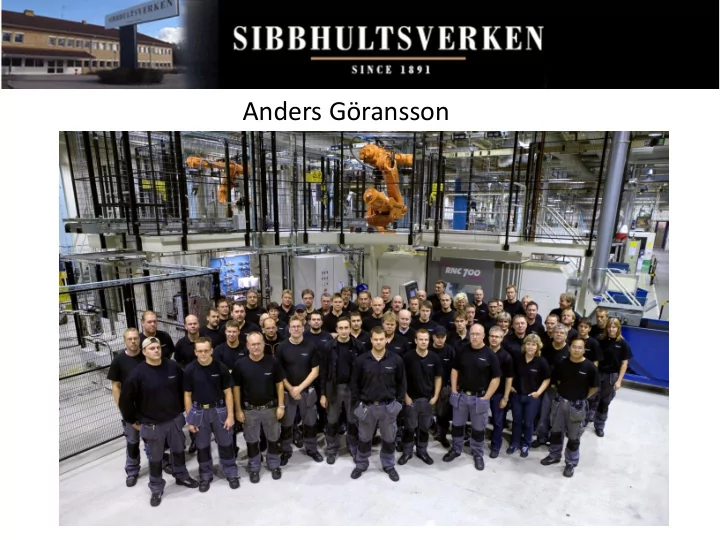

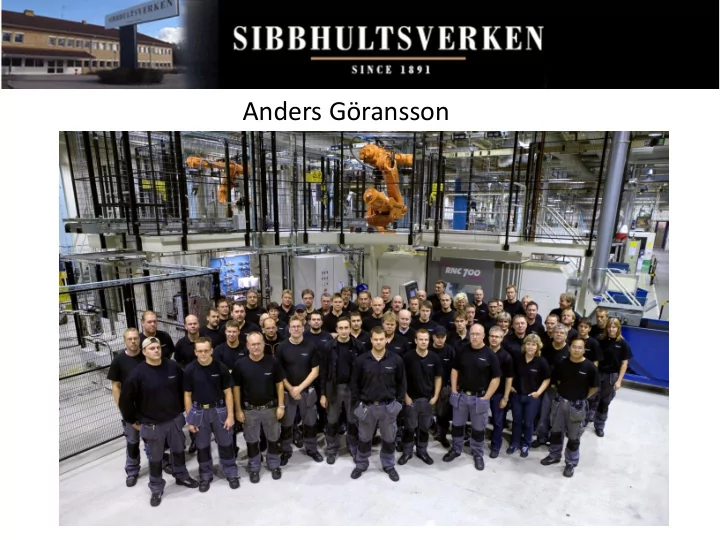

Anders Göransson

Klicka här för att ändra format Development of Hybrid drive concepts Electric drive axle for ExSAM hybrid systems for Mild hybrid systems for hybrid vehicle gearbox transmissions Diesel / petrol engines 2

Partners • Sibbhultsverken – Sub supplier of transmission parts – Mechanical design and production • MagComp – Producer electrical machines and drives – Electromagnetic design and production – IP owner Magnetic Molding techniques • IEA Lund University – Scientific partner. Have designed, built and tested 3 similar systems for car application (specialized licentiate ready early 2009, available for the proposed project from start 2010). – Electromagnetic design and testing • Volvo Powertrain – Bus and Truck producer. Problem owner. – Specification, system simulation and in vehicle testing

Background / challenge • With an In-line parallel hybrid ( Alt1 ) configuration the electric machine has a short axial length and wide diameter. • This gives a number of drawbacks: – Long Drive Train – High Inertia in Gear Shift – Cost • An Ex-line configuration ( Alt 2 ) means: – Less or no interference with valuable space – Lower Inertia = fast Gear Shift – Lower cost With an Ex-line a fast shifting, lower cost, hybrid transmission can be accomplished. In some applications this replaces Power Shift transmissions thus cutting cost further on vehicle level

Provrigg

ExSAM 2. Med ladd-slinga

Klicka här för att ändra format ExSAM 3 9

Recommend

More recommend