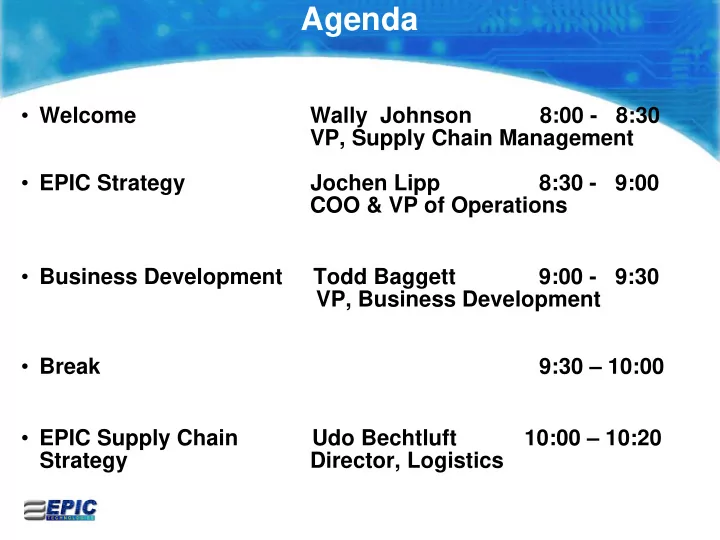

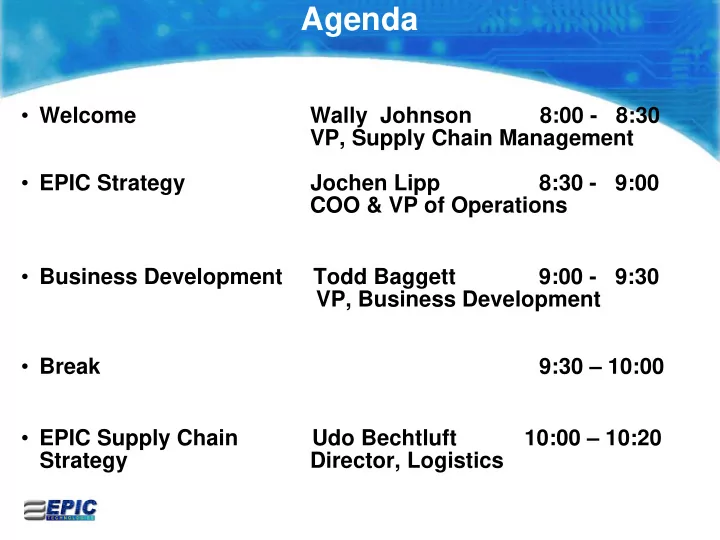

Agenda • Welcome Wally Johnson 8:00 - 8:30 VP, Supply Chain Management • EPIC Strategy Jochen Lipp 8:30 - 9:00 COO & VP of Operations • Business Development Todd Baggett 9:00 - 9:30 VP, Business Development • Break 9:30 – 10:00 • EPIC Supply Chain Udo Bechtluft 10:00 – 10:20 Strategy Director, Logistics

Agenda • IT Developments Marty Bentley 10:20 – 10:35 Director, IT • Commodity Management Louise Stump 10:35 – 10:50 Director, Purchasing • Supplier Development Hilario Apodaca 10:50 – 11:05 Director, Quality • 2006 Supplier of the Year Award Presentation 11:05 – 11:30 • Q & A – from submitted cards/Wrap-up/Survey 11:30 – 12:00 • Lunch 12:00 – 1:00

EPIC Mission and Values Statements Mission Statement • Our mission is to exceed our customers expectations as the “Best-In- Class” provider of full service electronic manufacturing and systems integration. Quality • EPIC will provide the highest quality products and services, when and where our customers need them. Continuous improvement will lead our pursuit of defect-free products and processes. People • Fundamental to our way of doing business is integrity and fairness with customers, employees, suppliers and shareholders. EPIC strongly believes that expanding the skills, capabilities and empowerment of our employees is key to our collective success. Profitability • EPIC will manage its business profitably to support our growth and enhance our shareholder’s value.

Synchronous Flow Manufacturing At EPIC Technologies, Synchronous Flow Manufacturing means never building product until our customers say they need it, as well as… • No “Frozen Windows” on Orders • 1 to 2 Day Order Turn Around Time • 99% On-Time Delivery to Customer Request • Incredible Inventory Turns for our Customers

Key EPIC Strategies • Customer Satisfaction • Lean Manufacturing • Synchronous Flow • Single Minute Exchange Die - SMED • Visual Techniques • 6 Sigma Quality • Continuous Improvement • MBO Targets are focused on worldwide “Best-in-Class” • Throughput Mentality • Customer Focus Teams • Training Investment • Elimination of Waste • Supply Chain Methodologies • Raw Material KanBan

Flexibility & Responsiveness 25,000 300,000 140,000 700,000 Net Rec Net Rec Cum 120,000 600,000 250,000 Cum 20,000 100,000 500,000 200,000 15,000 80,000 400,000 150,000 60,000 300,000 10,000 100,000 40,000 200,000 5,000 50,000 20,000 100,000 0 0 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 140,000 180,000 140,000 1,800,000 Net Rec 160,000 Net Rec 1,600,000 120,000 Cum 120,000 Cum 140,000 1,400,000 100,000 100,000 120,000 1,200,000 80,000 100,000 80,000 1,000,000 80,000 60,000 800,000 60,000 60,000 600,000 40,000 40,000 40,000 400,000 20,000 20,000 20,000 200,000 0 0 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Flexibility & Responsiveness 600 1,200,000 30,000 250,000 Net Rec Net Rec Cum 500 1,000,000 Cum 25,000 200,000 400 800,000 20,000 150,000 300 600,000 15,000 100,000 200 400,000 10,000 50,000 100 200,000 5,000 0 0 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 600 1,200,000 140,000 180,000 Net Rec Cum 160,000 Net Rec 500 1,000,000 120,000 Cum 140,000 100,000 400 800,000 120,000 80,000 100,000 300 600,000 80,000 60,000 200 400,000 60,000 40,000 40,000 100 200,000 20,000 20,000 0 0 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

EPIC Supply Model • EPIC Technologies core value proposition is to be able to deliver product ‘when and where’ the customer needs it in spite of forecasts being misaligned with actual requirements. • Flexibility and Responsiveness are fundamental principles of not only our operational execution but also our organizational philosophy. • The EPIC Supply Chain requires partners who are committed to this goal to help us work together on strategies and tactics to better enable us to satisfy our mutual end customers: • “Best in Class” Quality • Elimination of non-value add (Muda, or ‘waste’) • Short Cycle Times • Strategic buffers • Throughput Mentality

What Materials Needs to Be What Material Is Now

Supply Organization Wally Johnson VP Supply Chain Mgmt Cheryl Randleman Louise Stump Udo Bechtluft Mat'l Analysis Mgr Logistics Director Purchasing Director Norwalk Lou Nemeth Ralph Sperling Sukie Medina Miguel Barrenada Jerome Mettetal Lou Nemeth Purchasing Mgr Purchasing Mgr Acting Logistics Mgr Procurement Mgr Customs Mgr Purchasing Mgr Norwalk Plant 1 & 2 Norwalk Plant 1& 2 Plant 1 & 2 Johnson City Pam Jackson Dwaine Raper Martin Chapparo Joe Davis Purchasing Logistics Mgr Logistics Mgr Global Supply Mgr Johnson City Plant 1 & 2

EPIC 8:30 - 9:00 COO & VP of Operations Jochen Lipp Agenda • EPIC Strategy

North American Mfg Locations “ONE PLATFORM” All factories equipped with same MFG and Test equipment Norwalk El Paso • Over 500K/Sqft of Mfg South Lebanon • ISO 9001 :2000 Certified • ISO/TS-16949 Certified • ISO-13485 Certified (Juarez & Norwalk), JoCy Q2 ‘06 • FDA Registered Class II & III • IPC Class II & III Mfg Johnson City Juarez Plant 1 & 2 Currently Evaluating opportunies in Eastern European and Asia

EPIC Corporate Development Update • Since the completion of the Siemens and Philips acquisitions in FY’05 our focus has been on the successful integration of three facilities, more than doubling our manufacturing capacity, and adding key operational and managerial talent. • Now complete, the process went remarkably well, exceeding the expectations of our stakeholders and customers, particularly in operational performance and conversion to lean S.F.M. practices. • Corporate focus shifts to developing greater depth in EPIC’s senior management team and capitalizing on best practices among our operations.

Organization Chart – EPIC Technologies Acting CEO Randy Haight Todd Baggett Wally Johnson Jochen Lipp Steve Fries VP Business Development VP Supply Chain Mgmt COO CFO Steve Fraser Chris Munroe Hilario Apodaca Marty Bentley Uwe Steudle Mike Goryl Ugo Bechtluft Louise Stump Business U.S. Mfg Engineering Quality Mexico Mfg Purchasing Logistics Director Director Director Director IT Director Director HR Director Director Director Mike Washington Fabian Herrera U.S. Mexico Program Mgmt Mgr Program Mgmt Mgr Norwalk Mexico Plant 1 Johnson City Mexico Plant 2 Ohio Valley

EPIC Corporate Development Update • John Sammut’s request for leave of absence to devote full attention to his son’s critical illness was unanimously supported by our B.O.D. • To accommodate John’s personal needs, Randy Haight, a member of EPIC’s B.O.D. for the past three years, and a 13- year veteran of the EMS industry agreed to serve as acting President and CEO. • Randy works closely with Jochen Lipp to provide strategic direction to the company for the foreseeable future. This transition was transparent to our customers. Randy’s experience in a high growth environment adds a valued perspective to EPIC’s immediate future.

Synchronous Flow Manufacturing At EPIC Technologies, Synchronous Flow Manufacturing means never building product until our customers say they need it, as well as… • No “Frozen Windows” on Orders • 1 to 2 Day Order Turn Around Time • 99% On-Time Delivery to Customer Request • Incredible Inventory Turns for our Customers

EPIC's Synchronous Flow Principal • Motivated employees, which are flexible and well-trained in multiple operations Cellular-based layout designed to improve capacity • utilization and increase equipment / process flexibility Components at point-of-use; no raw material warehouse in • manufacturing plants • Flexible suppliers that can react quickly to pulls, supporting EPIC with bonded and consignment inventories • Significantly reduced set-up / change-over times enabling multiple product change-over's per shift and very small transfer quantities – greater flexibility for actual customer demand

EPIC's Synchronous Flow Principal • Close to no WIP, elimination of waste High First-pass yield at ICT and Functional Test through • small transfer quantities and “Lean System” Average production cycle times 1-2 days, in a lot of cases • less than 1 shift in a high-mix environment (e.g. producing 25-50 assemblies simultaneously in each work cell) • This enables rapid respond to customers’ daily pull signals with very high OTD, shipping products from “finished goods leveling system” triggering rapid replenishment

Steering Wheel • Represents the total allowable ‘universe’ of finished goods split into three groups • Finished Goods at the Customer (and in-transit) • Finished Goods at EPIC • Future Production Plan Finished Goods • WIP cards (Green, Yellow, Red) @ Customer @ EPIC • ‘Unscheduled’ (Grey) Production Plan

Recommend

More recommend