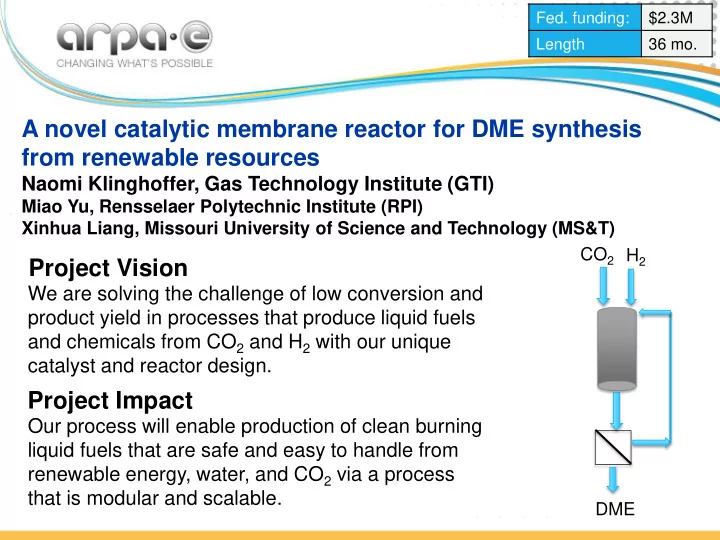

Fed. funding: $2.3M Length 36 mo. A novel catalytic membrane reactor for DME synthesis from renewable resources Naomi Klinghoffer, Gas Technology Institute (GTI) Miao Yu, Rensselaer Polytechnic Institute (RPI) Xinhua Liang, Missouri University of Science and Technology (MS&T) CO 2 H 2 Project Vision We are solving the challenge of low conversion and product yield in processes that produce liquid fuels and chemicals from CO 2 and H 2 with our unique catalyst and reactor design. Project Impact Our process will enable production of clean burning liquid fuels that are safe and easy to handle from renewable energy, water, and CO 2 via a process that is modular and scalable. DME

Innovation and Objectives Innovation Task outline, technical objectives Bifunctional catalyst and membrane BP1 reactor shift equilibrium towards Advanced catalyst development product formation Advanced membrane development Advanced catalyst synthesis BP2: Catalytic membrane reactor techniques for higher product yield testing to achieve target yield Membrane reactor design improves BP3: Prototype scale demonstration at catalyst performance by decreasing 1 kg/day, 150h stable operation deactivation by water Compact, modular design Tech-to-Market strategy H 2 H 2 O H 2 License technology DME CO 2 International DME Association members CO 2 + 3H 2 CH 3 OH + H 2 O 1. Packaged modular systems 2CH 3 OH CH 3 OCH 3 + H 2 O 2.

Innovation and Objectives Project history Proposed targets GTI & USC (RPI) collaborated on 3 Metric State of the Art Proposed DOE-supported membrane process Product 43% 60% projects related to gas storage and selectivity (at X CO2 = 15%) (at X CO2 = 15%) separations (natural gas storage, Catalyst Not reported for 150 h of stable CO 2 capture and O 2 production) stability this reaction operation DME Cost 0.11 $/kWh 0.09 $/kWh* GTI & MS&T collaborated on catalyst development for CO 2 activation *based on DOE target of $2/kg H 2 and air capture of CO 2 Desirable partnerships Anticipated challenges Reactor configuration – consult with Inorganic membrane fabricator MPT; advanced sealing materials Catalyst manufacturer Membrane performance at reaction Modular equipment fabricator conditions – modify membrane Catalyst coking - modify catalyst; tune water permeance of membrane

Preliminary Results Catalyst Testing 30 100 Selectivity (%) Catalyst Conversion (%) 25 80 20 • CuO/ZnO/Al 2 O 3 60/30/10) CO 60 15 • Incipient wetness synthesis 40 10 Methanol 20 5 Test pressure: 600 psi 0 0 200 250 300 200 250 300 Temperature ( o C) Temperature ( o C) NaA Membrane SEM images of membrane Testing at 80 o C Permeance Pressure H 2 O/CO 2 (mol ・ s -1 m -2 Pa -1 ) (psig) Selectivity H 2 O CO 2 1 7.7E-05 6.2E-07 120 2 8.5E-05 9.5E-07 89 3

Recommend

More recommend