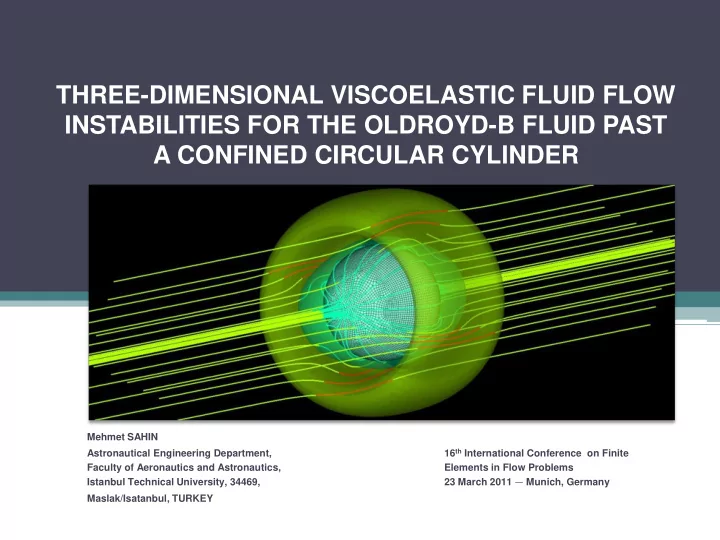

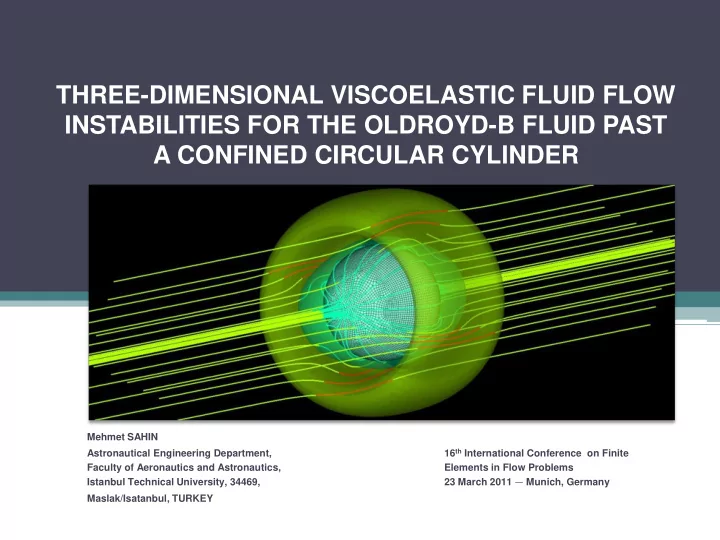

THREE-DIMENSIONAL VISCOELASTIC FLUID FLOW INSTABILITIES FOR THE OLDROYD-B FLUID PAST A CONFINED CIRCULAR CYLINDER Mehmet SAHIN 16 th International Conference on Finite Astronautical Engineering Department, Faculty of Aeronautics and Astronautics, Elements in Flow Problems 23 March 2011 — Munich, Germany Istanbul Technical University, 34469, Maslak/Isatanbul, TURKEY

Flow Instabilities in Newtonian and non-Newtonian Fluids Two-dimensional inertial instability Three-dimensional viscoelastic instability Three-dimensional inertial instability

The Mechanism for the non-Newtonian Flow Instabilities McKinley et al. (1996) suggested that for shear-dominated flows one destabilizing mechanism was a combination of streamline curvature and large elastic stresses along the streamlines, giving rise to an extra hoop stress in a direction normal to the streamlines, which can lead to instabilities. Tss R Tss This is similar to the Taylor-Couette instability but the direction of the hoop stress is in the reverse direction to the centrifugal force.

Polymer Processing Output quality constraints require that operating conditions should be maintained within the stable flow regime. Therefore polymer processing speed is limited by flow instabilities.

The Linear Stability (Normal Mode) Analysis for the Three-Dimensional Oldroyd-B Fluid Past Periodic Array of Cylinders with L=2.5R L For details see Sahin and Wilson JNNFM (2008)..

The Linear Stability (Normal Mode) Analysis for the Three-Dimensional Oldroyd-B Fluid Past Periodic Array of Cylinders with L=4.0R The linear stability analysis was not conclusive for L=4.0R due to the classical High Weissenberg Number problem.

Unstructured Finite Volume Formulation The governing equations of an incompressible Oldroyd-B fluid can be written in dimensionless form as follows: Integrating the differential equations over an arbitrary irregular control volumes

Numerical Discretization (a) Two-dimensional dual volume (b) Three-dimensional dual volume The side centered finite volume method used by Hwang (1995) and Rida et al. (1997). The present arrangement of the primitive variables leads to a stable numerical scheme and it does not require any ad-hoc modifications in order to enhance pressure-velocity-stress coupling. The most appealing feature of this primitive variable arrangement is the availability of very efficient multigrid solvers.

Numerical Discretization (Continued…) The discrete contribution from the right cell is given for the momentum equation along the x-axis. The time derivation: The convective term The pressure term The viscous term

Numerical Discretization (Continued…) The extra stress term The discretization of the constitutive equation for the Oldroyd-B fluid The gradient terms are calculated from the Green’s theorem In order to evaluate the face values of the extra-stress tensor, an upwind least square interpolation is employed.

Numerical Discretization (Continued…) Any component of the extra stress tensor can be extrapolated to control volume boundaries using a Taylor series expansion The neighbouring cell center values may be expressed as This over determined system may be solved in a least square sense. The discretization of the above governing equations lead to

Iterative Methods A time splitting scheme decouples the calculation of the extra stress tensor from the evaluation of the velocity and pressure fields by solving a generalized Stokes problem. However, the classical iterative methods (e.g. Richardson, Gauss-Seidel, Jacobi) and the multilevel methods can be applied directly because of the zero block in the saddle point problem. Then we will apply the two-level non-nested geometric multigrid preconditioner to solve the modified Stokes systems.

The Basic Idea of the Multigrid Method smoothing prolongation (interpolation) restriction Fine Grid Smaller Coarse Grid The basic idea of the multigrid method is to carry out iterations on a fine grid and then progressively transfer these flow field variables and residuals to a series of coarser grids. On the coarser grids, the low frequency errors become high frequency ones and they can be easily annihilated by simple explicit methods.

High Weissenberg Number Problem The relation between the conformation tensor and the extra stress tensor is given by The constitutive equation for the Oldroyd-B fluid in terms of the conformation tensor is given by The conformation tensor is a quantity that describes the internal microstructure of polymer molecules in a continuum level. The conformation tensor is symmetric and positive definite . Unless special care is taken, the conformation tensor may lose this property at high Weissenberg numbers and the numerical solution will soon diverge. Log conformation method is proposed by R. Fattal and R. Kupferman, J. Non- NewtonianFluid Mech. 123 (2004).

Log Conformation The constitutive equation for the Oldroyd-B fluid in terms of the conformation tensor It is possible to decompose the gradient of divergence free velocity field into nonsymmetric and tensors, and symmetric tensor. Use eigen decomposition theorem Then let The evolution equation for becomes Then the conformation tensor is positive definite.

Parallelization and Efficiency Mesh Generation (GAMBIT, CUBIT, ...) Mesh Partition (METIS library) Parallel Unstructured Finite Volume Code Linear Solver with Two-Level Multigrid Preconditioner Kroylov subspace methods (PETSc library) Preconditoners (PETSc library) Post Processing (Tecplot)

Computing Resources for Parallel Calculations • SGI Altix 3000 (1300MHz, Itanium 2) with 32 nodes • National Center for High Performance Computing of Turkey, • TUBITAK ULAKBIM, High Performance and Grid Computing Center

TEST CASE I: Two-Dimensional Oldroyd-B Fluid Past a Confined Circular Cylinder The computational coarse mesh (M1) with 35,313 quadrilateral element (DOF= 283,508 ). The ratio of the channel height to the cylinder diameter is 2.

TEST CASE I: Two-Dimensional Oldroyd-B Fluid Past a Confined Circular Cylinder The mesh convergence of Txx with mesh renement on the cylinder surface and in the cylinder wake at We = 0.7 with β =0.59 for an Oldroyd-B fluid.

TEST CASE I: Two-Dimensional Oldroyd-B Fluid Past a Confined Circular Cylinder The comparison of Txx with the numerical results of Yurun et al. (1999), Hulsen et al. (2005) and Afonso et al. (2009) on the cylinder surface and in the cylinder wake at We = 0.7 with β =0.59 for an Oldroyd-B uid.

TEST CASE I: Two-Dimensional Oldroyd-B Fluid Past a Confined Circular Cylinder The mesh convergence of Txx with mesh renement on the cylinder surface and in the cylinder wake at We = 0.8 with β =0.59 for an Oldroyd-B fluid.

TEST CASE I: Two-Dimensional Oldroyd-B Fluid Past a Confined Circular Cylinder At this point, we are not sure whether the extra stress along the center line in the wake should exhibit exponential unbounded growth with time to infinity or leads to a time-dependent solution for the present two- dimensional calculations. The RMS convergence for the extra stress tensor at We = 0.9 with β =0.59 for an Oldroyd-B fluid past a confined cylinder ( Δ t = 0.01).

TEST CASE II: Oldroyd-B Fluid Flow around a Sphere Falling in a Circular Tube Wake refinement The computational mesh with 1,190,376 hexahedral element (DOF= 19,117,980 ). The ratio of the tube diameter to the sphere diameter is 2.

TEST CASE II: Oldroyd-B Fluid Flow around a Sphere Falling in a Circular Tube The computed u -velocity component isosurfaces with streamtrace plot for an Oldroyd-B fluid around a falling sphere in a circular tube at We=0.6 with β =0.50.

TEST CASE II: Oldroyd-B Fluid Flow around a Sphere Falling in a Circular Tube The computed Txx extra stress tensor component isosurfaces with contour plots on y = 0 plane (black lines) and on solid walls (red lines) for an Oldroyd-B fluid around a falling sphere in a circular tube at We=0.6 with β =0.50. Maximum Txx=35.14, W. J. Lunsmann et al. (1993) Maximum Txx=34.73, present .

TEST CASE II: Oldroyd-B Fluid Flow around a Sphere Falling in a Circular Tube The comparison of Txx with the results of Owens and Phillips (1996) on the sphere surface for an Oldroyd-B fluid around a falling sphere in a circular tube at We = 0.6 with β =0.59.

TEST CASE III: Three-Dimensional Oldroyd-B Fluid Past a Confined Circular Cylinder in a Rectangular Channel The computational mesh with 582,400 hexahedral element (DOF= 9,397,972 ). The ratio of the channel height to the cylinder diameter is 2. The ratio of channel width to the channel height is 5.

TEST CASE III: Three-Dimensional Oldroyd-B Fluid Past a Confined Circular Cylinder in a Rectangular Channel The computed Txx contours at We=0.7 for the Oldroyd-B fluid past a confined circular cylinder in a rectangular channel. Contour levels are 0, 0.1, 2, 4 and 8.

TEST CASE III: Three-Dimensional Oldroyd-B Fluid Past a Confined Circular Cylinder in a Rectangular Channel The computed isobaric surfaces at We=0.7 for the Oldroyd-B fluid past a confined circular cylinder in a rectangular channel.

TEST CASE III: Three-Dimensional Oldroyd-B Fluid Past a Confined Circular Cylinder in a Rectangular Channel The computed Txx contours at We=2.0 for the Oldroyd-B fluid past a confined circular cylinder in a rectangular channel. Contour levels are 0, 0.1, 4 and 8.

Recommend

More recommend