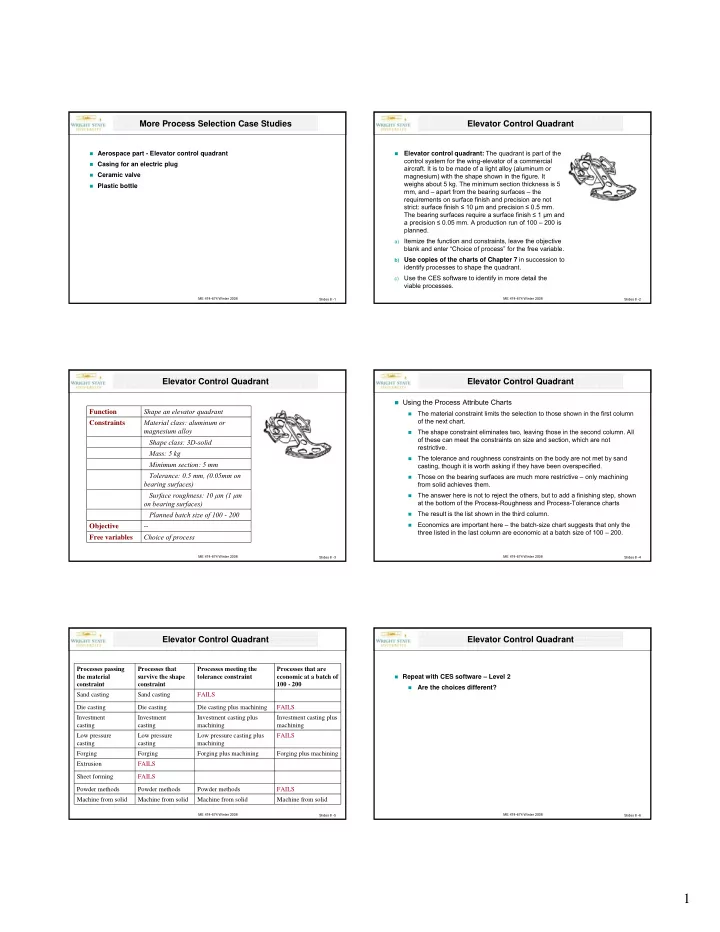

More Process Selection Case Studies Elevator Control Quadrant Elevator control quadrant: The quadrant is part of the � Aerospace part - Elevator control quadrant � control system for the wing-elevator of a commercial � Casing for an electric plug aircraft. It is to be made of a light alloy (aluminum or � Ceramic valve magnesium) with the shape shown in the figure. It weighs about 5 kg. The minimum section thickness is 5 � Plastic bottle mm, and – apart from the bearing surfaces – the requirements on surface finish and precision are not strict: surface finish ≤ 10 μ m and precision ≤ 0.5 mm. The bearing surfaces require a surface finish ≤ 1 μ m and a precision ≤ 0.05 mm. A production run of 100 – 200 is planned. Itemize the function and constraints, leave the objective a) blank and enter “Choice of process” for the free variable. b) Use copies of the charts of Chapter 7 in succession to identify processes to shape the quadrant. Use the CES software to identify in more detail the c) viable processes. ME 474-674 Winter 2008 Slides 8 -1 ME 474-674 Winter 2008 Slides 8 -2 Elevator Control Quadrant Elevator Control Quadrant � Using the Process Attribute Charts Shape an elevator quadrant Function The material constraint limits the selection to those shown in the first column � of the next chart. Material class: aluminum or Constraints magnesium alloy The shape constraint eliminates two, leaving those in the second column. All � of these can meet the constraints on size and section, which are not � Shape class: 3D-solid restrictive. � Mass: 5 kg The tolerance and roughness constraints on the body are not met by sand � � Minimum section: 5 mm casting, though it is worth asking if they have been overspecified. � Tolerance: 0.5 mm, (0.05mm on Those on the bearing surfaces are much more restrictive – only machining � bearing surfaces) from solid achieves them. � Surface roughness: 10 μ m (1 μ m The answer here is not to reject the others, but to add a finishing step, shown � on bearing surfaces) at the bottom of the Process-Roughness and Process-Tolerance charts The result is the list shown in the third column. � Planned batch size of 100 - 200 � Economics are important here – the batch-size chart suggests that only the -- Objective � three listed in the last column are economic at a batch size of 100 – 200. Choice of process Free variables ME 474-674 Winter 2008 Slides 8 -3 ME 474-674 Winter 2008 Slides 8 -4 Elevator Control Quadrant Elevator Control Quadrant Processes passing Processes that Processes meeting the Processes that are � Repeat with CES software – Level 2 the material survive the shape tolerance constraint economic at a batch of constraint constraint 100 - 200 Are the choices different? � Sand casting Sand casting FAILS Die casting Die casting Die casting plus machining FAILS Investment Investment Investment casting plus Investment casting plus casting casting machining machining Low pressure Low pressure Low pressure casting plus FAILS casting casting machining Forging Forging Forging plus machining Forging plus machining Extrusion FAILS Sheet forming FAILS Powder methods Powder methods Powder methods FAILS Machine from solid Machine from solid Machine from solid Machine from solid ME 474-674 Winter 2008 ME 474-674 Winter 2008 Slides 8 -5 Slides 8 -6 1

Casing for an electric plug Casing for an electric plug The electric plug is perhaps the commonest of � electrical products. It has a number of components, Shape an electric plug casing Function each performing one or more functions. The most Material class: Material class: Constraints obvious are the casing and the pins, though there are thermoplastic or thermosetting many more (connectors, a cable clamp, fasteners, and, in some plugs, a fuse). The task is to investigate � Shape class: 3D-solid processes for shaping the two-part insulating casing, the thinnest part of which is 2 mm thick. Each part � Mass: 0.03 kg weighs about 30 grams and is to be made in a single � Minimum section: 2 mm step from a thermoplastic or thermosetting polymer with a planned batch size of 5 x 10 4 – 2 x 10 6 . The required � Tolerance: 0.3 mm tolerance of 0.3 mm and surface roughness of 1 μ m � Surface roughness: 1 μ m must be achieved without using secondary operations. � Planned batch size of 5 x10 4 – 2 x10 6 (a) Itemize the function and constraints, leave the objective blank and enter “Choice of process” for the free -- Objective variable. Choice of process Free variables (b) Use the charts of Chapter 7 successively to identify possible processes to make the casing (c) Use the CES software to select processes for making the casing. ME 474-674 Winter 2008 Slides 8 -7 ME 474-674 Winter 2008 Slides 8 -8 Casing for an electric plug Ceramic valves for faucets Many household faucets now have ceramic valves replacing faucets � in which rubber washers tended to wear or brass surfaces tended to � Here we seek a net-shape process – the casing must be shaped in one corrode operation without the need for any further finishing. Ceramics wear well, and they have excellent corrosion resistance in � � Applying the constraints as shown in the Process Attribute Charts and both pure and salt water. eliminating processes that fail a constraint leaves two candidates: A ceramic valve consists of two disks mounted one above the other, � Injection molding and compression molding spring-loaded so that their faces are in contact. Each disk has a � diameter of 20 mm, a thickness of 3 mm and weighs about 10 � CES-EduPack results in the same choices grams. In order to seal well, the mating surfaces of the two disks must be flat and smooth, requiring high levels of precision and surface finish; typically tolerance < 0.02 mm and surface roughness < 0.1 μ m. The outer face of each has a slot that registers it, and allows the upper disc to be rotated through 90o (1/4 turn). In the “off” position the holes in the upper disc are blanked off by the solid part of the lower one; in the “on” position the holes are aligned. A production run of 10 5 –10 6 is envisaged. List the function and constraints, leave the objective blank and enter � “Choice of process” for the free variable. Use the charts of Chapter 7 to identify possible processes to make � the valve. Use the CES software to select processes for making the valve. � ME 474-674 Winter 2008 Slides 8 -9 ME 474-674 Winter 2008 Slides 8 -10 Ceramic valves for faucets Ceramic valves for faucets Shape a ceramic valve for faucets � Applying the constraints using the Process Attribute Charts, and Function eliminating processes that fail a constraint leaves only one candidate: Material class: technical ceramic Constraints powder methods. • Shape class: prismatic � The CES selection distinguishes several powder processes. The two • Mass: 0.01 kg meet all the requirements except those on precision and tolerance are • Minimum section: 3 mm � Pressing and sintering • Tolerance: 0.02 mm � Powder injection molding • Surface roughness: 0.1 μ m � A separate grinding and polishing operation must be added to • Planned batch size of 10 5 –10 6 meet the precision and tolerance requirements -- Objective Choice of process Free variables ME 474-674 Winter 2008 ME 474-674 Winter 2008 Slides 8 -11 Slides 8 -12 2

Shaping plastic bottles Shaping plastic bottles � Plastic bottles are used to contain fluids as various as milk and engine � Applying the constraints as shown Shape a polyethylene bottle Function on the Charts eliminating processes oil. A typical polyethylene bottle weighs about 30 grams and has a that fail a constraint in the manner of Material class: Polyethylene (or wall thickness of about 0.8 mm. The shape is 3-D hollow. The batch Constraints the table shown previously leaves only thermoplastic) size is large (1,000,000 bottles). What process could be used to make two candidates: blow molding and • Shape class: 3-D hollow them? injection molding. � At Level 1 and 2 the CES selection is • Mass: 0.02 – 0.04 kg � List the function and constraints, leave the objective blank and the same as that derived from the enter “Choice of process” for the free variable. • Minimum section: 0.7 - 1 mm charts. � Use the Process Attribute charts to identify possible processes to • Tolerance: 1 mm � At Level 3 CES distinguishes two variants of blow molding, identifying make the bottles. • Surface roughness: 10 μ m injection blow molding, as the best � Use the CES software to select processes for making the bottles. choice because it can provide the • Planned batch size >10 6 desired change of section. -- Objective Commercially, plastic bottles are made using injection blow molding. Choice of process Free variables ME 474-674 Winter 2008 Slides 8 -13 ME 474-674 Winter 2008 Slides 8 -14 3

Recommend

More recommend