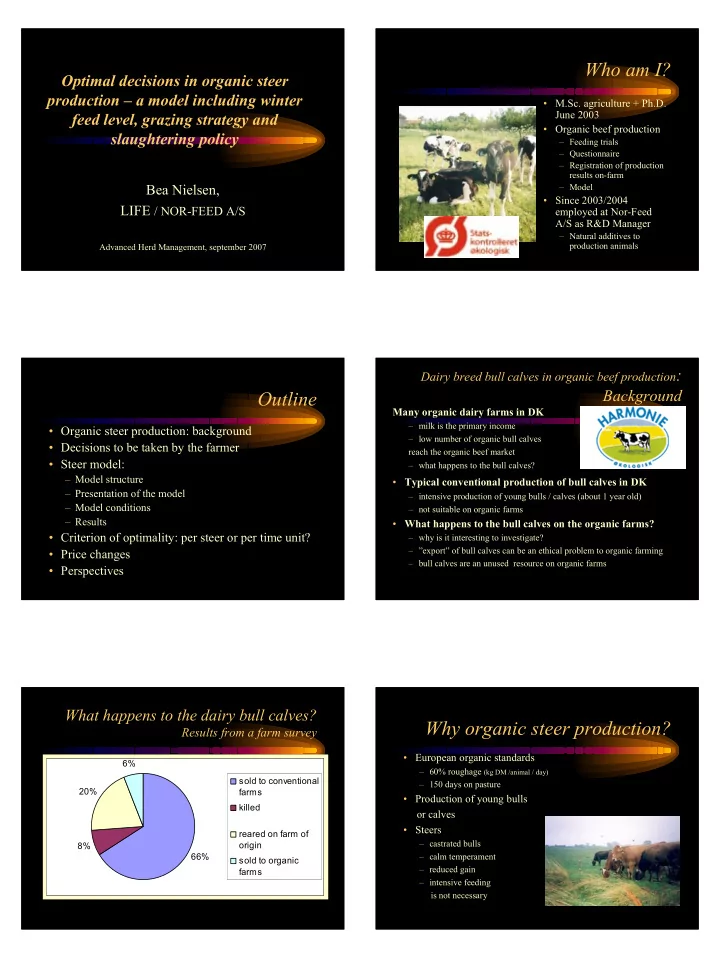

Who am I? Optimal decisions in organic steer production – a model including winter • M.Sc. agriculture + Ph.D. June 2003 feed level, grazing strategy and • Organic beef production slaughtering policy – Feeding trials – Questionnaire – Registration of production results on-farm Bea Nielsen, – Model • Since 2003/2004 LIFE / NOR-FEED A/S employed at Nor-Feed A/S as R&D Manager – Natural additives to production animals Advanced Herd Management, september 2007 Dairy breed bull calves in organic beef production : Background Outline Many organic dairy farms in DK – milk is the primary income • Organic steer production: background – low number of organic bull calves • Decisions to be taken by the farmer reach the organic beef market • Steer model: – what happens to the bull calves? – Model structure • Typical conventional production of bull calves in DK – Presentation of the model – intensive production of young bulls / calves (about 1 year old) – Model conditions – not suitable on organic farms – Results • What happens to the bull calves on the organic farms? • Criterion of optimality: per steer or per time unit? – why is it interesting to investigate? – ”export” of bull calves can be an ethical problem to organic farming • Price changes – bull calves are an unused resource on organic farms • Perspectives What happens to the dairy bull calves? Why organic steer production? Results from a farm survey • European organic standards 6% – 60% roughage (kg DM /animal / day) sold to conventional – 150 days on pasture 20% farms • Production of young bulls killed or calves • Steers reared on farm of – castrated bulls 8% origin 66% – calm temperament sold to organic – reduced gain farms – intensive feeding is not necessary

Steer production Decisions to be taken 614 kg 600 900 g/d • Which pasture? 500 W eight, kg 602 kg 400 – marginal grass (low quality and gain) 300 – clover grass (high quality and gain) 900 g/d 600 g/d 600 g/d 200 • Feeding level in winter? 100 600 g/d Summer – low feeding level result in compensatory 0 1.1 1.5 1.11 1.5 1.11 1.1 growth on pasture Summer Months • When should fattening start? intensive extensive • Slaughter weight? The steer model Model structure: Action space • 4-level hierarchical Markov process with Founder Child level 1 Child level 2 Child level 3 decisions defined at three levels Proces – child level 1: Dummy Summer: Continue or Keep or start slaughter • grazing strategy (marginal grass or clover grass), Marginal grass or fattening or clover grass • feed level in winter (high and low) slaughter Winter: – child level 2: time for beginning of fattening High or low (19-27 months) feeding level – child level 3: time of slaughter (19-30 months) The steer model: Founder process Model structure Founder Child level Child level Child level • process tree Proces 1 2 3 Time Infinite Finite Finite Finite • state space: birth horizon month, 12 levels Stage Life span of grazing / stage1: 1 month length the steer winter until 19 season months stage2-6: 1 month State Birt month Live Live Live space weight weight weight gain gain

Child level 1 Child level 1 • stable period • stages of child level 1: stable and – action space: low and high grazing periods • grazing period – state space: 7 weight levels – low and high previous winter feeding – action space Child level 2 Child level 3 • 2 grazing period • action child level 2: start fattening – clover grazing is chosen • 4 stages in child – child level 2 is defined - age of 19 months is level 3 (19-22 reached months) – at 19 months (August) • 3 states (weight fattening can start gains) – stage length • action: keep and – action space replace Model Parameters conditions

Simulation: Gain per steer Model conditions • Growth on clover grass pastures following low winter feeding • steers born January Optimal strategy in the second grazing period Optimal strategies for all seasons (child level 1) according to month of birth and (child level 1) for steers born in August. LW. Permanent pasture following high feed level Clover pastures following low feed level Optimal strategies at child level 2 are shown for Optimal strategy in the second grazing period (child level 1) according to previous winter feed level, examples of month of birth steers born in January in the third stable period with low feeding level. and LW at the beginning of the period. Month of Previous winter LW at the beginning of Optimal pasture birth feed level the period, kg decision January Irrespective Irrespective Ryegrass/clover March Irrespective 240-360 Ryegrass/clover Irrespective 230 Permanent May Irrespective 220-240 Permanent Irrespective 250-330 Ryegrass/clover July High 350-410 Permanent High 420-610 Ryegrass/clover Low Irrespective Ryegrass/clover September High 330-400 Permanent High 410-590 Ryegrass/clover Low Irrespective Ryegrass/clover November High 310-400 Permanent High 410-470 Ryegrass/clover Low 310-470 Ryegrass/clover

Optimal strategies at child level 3 steers born in January in the third stable period at low feeding level, a LW Net return, DKK/steer of 470 kg at the beginning of the third stable period and with the beginning of fattening in January at an age of 24 months. 600 Net return relative to minimum 500 net return, DKK/steer 400 300 200 100 0 JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC Months of birth Optimal slaughter weight, kg Conclusions 600 • child level 1 Optimal slaughter weight, kg 500 – low feeding level in winter 400 – permanent pastures the 1. grazing season 300 – clover pastures for steers with high liveweight 200 • child level 2 100 0 – only few steers should be fattened JAN MAR APR MAY JUN JUL AUG NOV FEB SEP OCT DEC • child level 3 Months of birth Is the hierarchic Markov proces useful to describe the given problem ? Optimal criterion • organic steer production has well defined phases Per steer Per time unit • decisions are linked to these phases • well suited for the state and action spaces of Replacement the multi-level hierarchic Markoc proces with a new steer • a big model (474,000 state combinations), but the hierarchic structure makes it Net return per produced Net return per year possible steers is maximised is maximised

Recommend

More recommend