VICTORY PROCESS Full Physical 3D Semiconductor Simulator Etching - PowerPoint PPT Presentation

VICTORY PROCESS Full Physical 3D Semiconductor Simulator Etching and Deposition Simulation VICTORY Process 3D Process Simulator VICTORY Process provides the capability to simulate comprehensive full process flows Etching, Deposition

VICTORY PROCESS Full Physical 3D Semiconductor Simulator Etching and Deposition Simulation

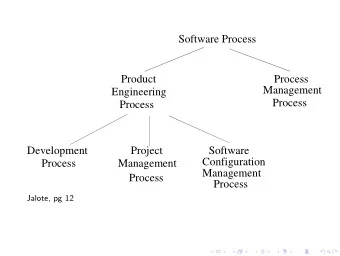

VICTORY Process – 3D Process Simulator VICTORY Process provides the capability to simulate comprehensive full process flows Etching, Deposition Oxidation, Stress Implantation Diffusion Self explanatory process flow description Open interface for modeling Model parameters and functions can be accessed and modified Open C-function library is used to implement the models Precompiled model library is provided - 2 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Level Set Framework The structure is represented as a set of implicit surfaces Hierarchical Cartesian meshes are used to improve the accuracy around critical areas Support for automatic and manual mesh refinement - 3 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Level Set Framework Very stable surface propagation algorithms Automatic void detection Avoids the problem of loops creation and correction - 4 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Etching / Deposition Modes Geometrical Mode Physical Mode + Numerical error is limited by the mesh + Simulates real physical processes size only + Accurately handles complex shading + Orders of magnitude faster than and visibility effects physical simulation of corresponding + Comprehensive set of models process + Can be extended via open modeling - Emulates a limited number of idealized interface processing steps - Slower than geometrical mode - Does not support shading effects - 5 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Geometrical Mode Comprehensive mask support GDSII – format masks lay – format masks (MaskViews) Definition of mask polygons inside the processing deck Mask variations via the deck (shrink and expand) Selection of a simulation window - 6 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Geometrical Mode Lithography Calculation of aerial images Pattern transfer of aerial images aerial image transferred pattern mask layer - 7 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Geometrical Mode Geometrical Etching Idealized directional mask pattern or image transfer Pattern transfer with tilted sidewalls and rounded corners with tilted sidewalls ideal pattern transfer and rounded corners with tilted sidewalls - 8 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Geometrical Mode Geometrical Etching Idealized wet and dry etching Selective and non-selective mode wet etching initial structure wet selective etching dry etching - 9 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Geometrical Mode Geometrical CMP Idealized planarization Selective and non-selective mode Non-Selective Selective - 10 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Geometrical Mode Geometrical Deposition Idealized vertical resists or material regions defined by a mask Idealized conformal deposition Deposition of features with tilted sidewalls and rounded corners Planar mode to partially fill holes Conformal Deposition Planar Deposition - 11 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Geometrical Mode - Summary Set of models for fast structure manipulation Based on idealized processing steps Used for fast structure prototyping and to create the initial shapes for subsequent physical analysis - 12 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode Reactor-Scale vs. Feature-Scale The numerical engine of VICTORY Process only operates on the feature scale level Ballistic transport within the simulation domain is assumed Constant particle properties within the simulation domain are assumed Particle-particle interactions within the gas region are ignored Reactor scale conditions are an input to the simulation order of 10 um Feature-scale Reactor-Scale Simulation domain of VICTORY Process Substrate Wafer - 13 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode Numerical Engine : Calculates the amount of reactants reaching the surface from the reactor domain Takes into account secondary effects Re-deposition of removed material Reflection of reactants Calculates the surface propagation Open Model Library (accessible and extendible) : Provides information on particle fluxes coming from the reactor Specifies the distribution of particle re-emission and refection Determines how the mix of reactants at the surface affects the structure Local (for each surface point) etching or deposition rates are calculated - 14 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode Boundary Conditions : The structure is symmetrically and periodically extended in X and Y directions. This is necessary to properly take into account secondary effects. The number of 'reflections' depends on the desired redeposition accuracy Shading effects and visibility are taken into account for all 'reflections' Simulation domain - 15 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode Etching Models without Particle Flux Particle flux is not taken into account No visibility and shading effects are taken into account Selective etching capability Isotropic Etching Model Anisotropic Etching Model selective isotropic etching initial structure selective anisotropic etching - 16 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode Deposition Models without Particle Flux Particle flux is not taken into account No visibility and shading effects are taken into account Selective deposition capability Conformal Deposition Model Non-conformal Deposition Model Conformal Selective Deposition Non-Conformal Selective Deposition initial structure - 17 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode Etching and Deposition Models with a Single Primary Particle Only the flux of a single particle coming from the reactor is taken into account Full consideration of visibility and shading effects The spacial velocity distribution of the particles coming from the reactor is an input to the model C-function in the open model library The spacial velocity distribution of the particles which are reflected from the surface is an input to the model C-function in the open model library The C-functions can be parametrized with parameters accessible through the input deck You can chose from a predefined set of distribution functions or create your own functions - 18 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode Etching Models with a Single Primary Particle where Surface Reflection is neglected For these models a high sticking efficiency is implicitly assumed Hence surface reflection can be neglected Selective etching capability The etch rate is a linear function of the local particle flux Directional Etching Model PrimaryOnly Etching Model RIE Etching Model - 19 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode Directional Etching Model Is a single primary particle etching model The velocity vector of all particles coming from the reactor is identical and by default perpendicular to the plane wafer surface initial structure selective directional etching - 20 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode Primary Etching Model Is a single primary particle etching model The spacial velocity distribution of the particles can vary from an isotropic distribution (default) to a highly focused distribution Width of the distribution function may be used as a parameter Isotropic Flux Cos 3 Flux initial structure primary etching model compared with idealized models - 21 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode RIE Etching Model Is a single primary particle etching model The two physical particles (ion and neutral) are superimposed in one flux distribution This is possible because secondary fluxes are neglected and identical surface interaction (reaction) properties are assumed for both particles : rate is linearly proportional to the flux Particles are differentiated by the surface material In the model the incoming flux distribution depends on the surface material The RIE model is used for DRIE (Bosch) process simulation (etching cycle) - 22 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode RIE Etching Model The spacial velocity distribution of the ions is highly focused Von Mises spacial velocity distribution is applied The standard deviation is used as a parameter The spacial velocity distribution of the neutral is isotropic Ratio between the two components (neutrals – ions) on the plane surface is used as a parameter - 23 - Full Physical 3D Semiconductor Simulator

VICTORY Process – Physical Mode RIE Etching Model initial structure etching with RIE model profile sensitivity to RIE model parameters (ion focus, ion/neutral ratio) - 24 - Full Physical 3D Semiconductor Simulator

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.