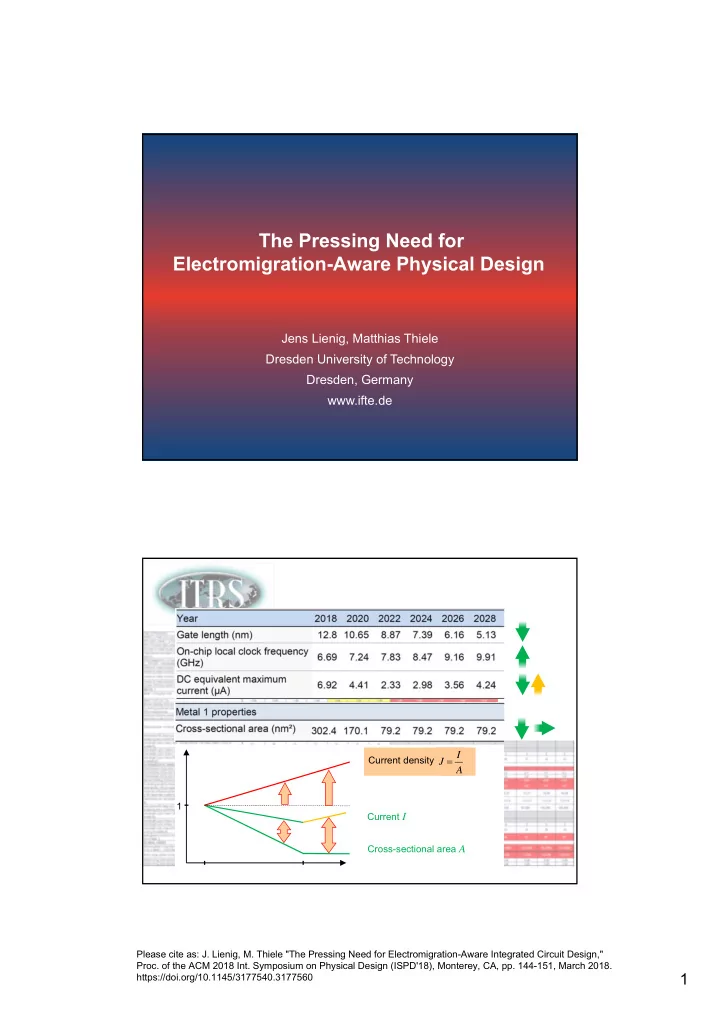

The Pressing Need for Electromigration-Aware Physical Design 1 Jens Lienig, Matthias Thiele Dresden University of Technology Dresden, Germany www.ifte.de J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 1 https://doi.org/10.1145/3177540.3177560 2 I J Current density A 1 Current I Cross-sectional area A J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 2 https://doi.org/10.1145/3177540.3177560 Please cite as: J. Lienig, M. Thiele "The Pressing Need for Electromigration-Aware Integrated Circuit Design," Proc. of the ACM 2018 Int. Symposium on Physical Design (ISPD'18), Monterey, CA, pp. 144-151, March 2018. 1 https://doi.org/10.1145/3177540.3177560

3 J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 3 https://doi.org/10.1145/3177540.3177560 Manufacturable EM-robust solutions are NOT known Interconnect is EM-affected 4 J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 4 https://doi.org/10.1145/3177540.3177560 2

Minimum gate length in nm 16 14 12 10 8 6 Current density 6 in MA/cm 2 5 4 3 2 5 1 0 2016 2018 2020 2022 2024 2026 Year Current density needed to drive four inverter gates J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 5 https://doi.org/10.1145/3177540.3177560 Contents 1 Introduction to Electromigration (EM) 2 Mitigating EM in Physical Design – What are Today’s Options? 3 Outlook – What to Do in the “Red Area”? 6 4 Summary J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 6 https://doi.org/10.1145/3177540.3177560 3

Introduction: Electromigration Electromigration (EM): Electromigration is the forced movement of metal ions due to an electric field F total = F direct + F wind Direct action of Force on metal ions resulting from << electric field on momentum transfer from the metal ions conduction electrons 7 Anode Anode Cathode Cathode Cu + - + + - - E - - J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 7 https://doi.org/10.1145/3177540.3177560 Introduction: Electromigration Metal atoms (ions) travel towards the positive end of the conductor while vacancies move towards the negative end Effects of electromigration in metal interconnects: • Atomic depletion (voids): Voids Slow reduction in connectivity Interconnect failure 8 • Atomic deposition (hillocks, whiskers): Short-cuts Hillocks J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 8 https://doi.org/10.1145/3177540.3177560 4

Electromigration and Current Density Black’s Equation: Median time to failure (MTF) of a single segment due to electromigration Cross-sectional-area- Activation energy dependent constant for electromigration MTF � � � � � � · exp � · � 9 Temperature Current density Scaling factor Boltzmann constant (usually set to 2) Current density is key to addressing electromigration Black, J.R. : “Electromigration - A brief survey and some recent results”; during physical design Proc. of IEEE Reliability Physics Symposium , Washington D.C., 1968 . J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 9 https://doi.org/10.1145/3177540.3177560 Maximum Tolerable Current Densities • Conventional metal wires (house wiring, etc.) 19,100 A/cm 2 Al 30,400 A/cm 2 Cu … reaching melting temperature due to Joule heating Melting temperature limits maximum current densities • Thin film interconnect on integrated circuits can sustain current densities 10 up to 10 10 A/cm 2 before reaching melting temperature, however, at Al 200,000 A/cm 2 (J max (Cu) 5* J max (Al) ) 1,000,000 A/cm 2 Cu … it reaches its maximum value due to the occurance of electromigration Electromigration limits maximum current densities J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 10 https://doi.org/10.1145/3177540.3177560 5

Maximum Tolerable Current Densities • Rule of Thumb for Copper IC Interconnects 10,000 - 100,000 A/cm 2 Electromigration to be considered 500,000 Effects visible A/cm 2 30,000,000 Rapid destruction A/cm 2 (25°C, Source: AMD Saxony) 11 Electromigration limits maximum current densities J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 11 https://doi.org/10.1145/3177540.3177560 Contents 1 Introduction to Electromigration (EM) 2 Mitigating EM in Physical Design – What are Today’s Options? 3 Outlook – What to Do in the “Red Area”? 12 4 Summary J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 12 https://doi.org/10.1145/3177540.3177560 6

Mitigating EM in Physical Design – What are Today’s Options? Local current density Wire widths, double/multiple vias Surface diffusion in Cu Surface coating, metal capping Bamboo effect Wire widths Short-length effects Segment lengths 13 Impact of voids Via-above/via-below configurations Reservoir effect (Metal-via) overlaps, multiple vias Damage-healing (self-healing) Frequency of the current effect J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 13 https://doi.org/10.1145/3177540.3177560 Bamboo Effect I = constant Diffusion MTF [h ] T = constant – + w Grain Boundary 14 w < Grains w Grains (Bamboo Wires) Wire Width w [ m ] w MTF_min J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 14 https://doi.org/10.1145/3177540.3177560 7

Bamboo Effect I = constant Diffusion MTF [h ] T = constant – + w Grain Boundary 15 Practical Applications* w ≤ 850 nm * Damascene Copper [Ar99] w < Grains w = Grains (Bamboo Wires) Wire Width w [ m ] w MTF_min J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 15 https://doi.org/10.1145/3177540.3177560 Short-Length Effects: (1) Blech Immortality Condition F N1 F N2 F N3 F N4 F N5 Electromigration (EM) Stress Migration (SM) – + Cu+ Cu+ Cu+Cu+ Cu+ Cu+ F N1 F N2 F N3 F N4 F N5 Tensile 16 – Cu+ Cu+ Cu+ Cu+ Cu+ + Cu+ Cu+ Compressive Stress F N1 F N2 F N3 F N4 F N5 Tensile Compressive Stress Equilibrium between EM and SM – + Cu+ Cu+Cu+ Cu+ Cu+ Cu+ if L segment < “Blech length” J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 16 https://doi.org/10.1145/3177540.3177560 8

Short-Length Effects: (1) Blech Immortality Condition F N1 F N2 F N3 F N4 F N5 Electromigration (EM) Stress Migration (SM) – + Al+Al+ Al+ Al+ Al+ Al+ F N1 F N2 F N3 F N4 F N5 17 – Al+ Al+ Al+ + Al+ Al+ Al+ Al+ F N1 F N2 F N3 F N4 F N5 Practical Applications L segment ≤ 5 - 50 µm Equilibrium between EM and SM – + Al+ Al+ Al+ Al+ Al+ Al+ if L segment < “Blech length” J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 17 https://doi.org/10.1145/3177540.3177560 Short-Length Effects: (2) Void Growth Saturation Electromigration (EM) Tensile Compressive Stress Cap Layer 18 e - Liner Layer – + Void Metal (Cu) Metallic Barrier (Liner) Dielectric Passivation (Cap Layer) J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 18 https://doi.org/10.1145/3177540.3177560 9

Short-Length Effects: (2) Void Growth Saturation Electromigration (EM) Stress Migration (SM) Tensile Compressive Stress 19 e - – + Void Void growth saturation due to mechanical stress buildup if JL segment < JL saturation Metal (Cu) Metallic Barrier (Liner) Dielectric Passivation (Cap Layer) J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 19 https://doi.org/10.1145/3177540.3177560 Short-Length Effects: (2) Void Growth Saturation Electromigration (EM) Stress Migration (SM) Tensile Compressive Stress Cap Layer 20 Liner Layer – + Void Void growth saturation due to mechanical stress buildup if JL segment < JL saturation Practical Applications* ( JL) saturation = 375 A/cm (Cu, low- k ) … 3,700 A/cm (Cu, high- k ) ≤ 7.5 µm … 74 µm L *J = 5 x 10 5 A/cm 2 , [HR03][LE02] J. Lienig, M. Thiele: The Pressing Need for Electromigration-Aware Physical Design, Proc. of ISPD 2018, pp. 144-151, 20 https://doi.org/10.1145/3177540.3177560 10

Recommend

More recommend