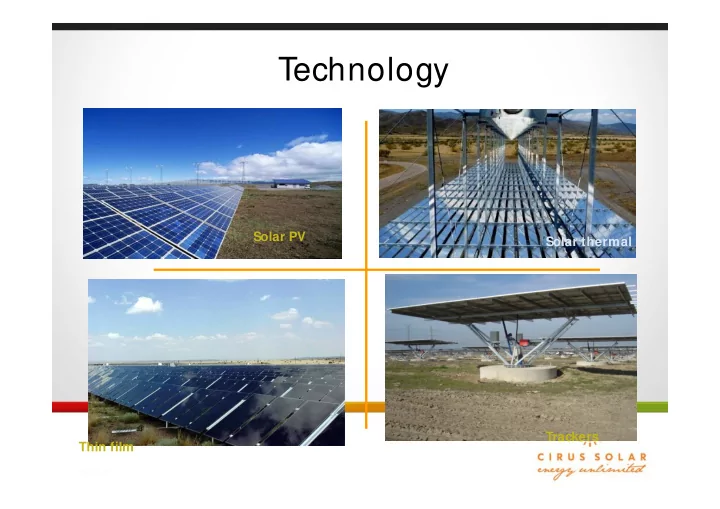

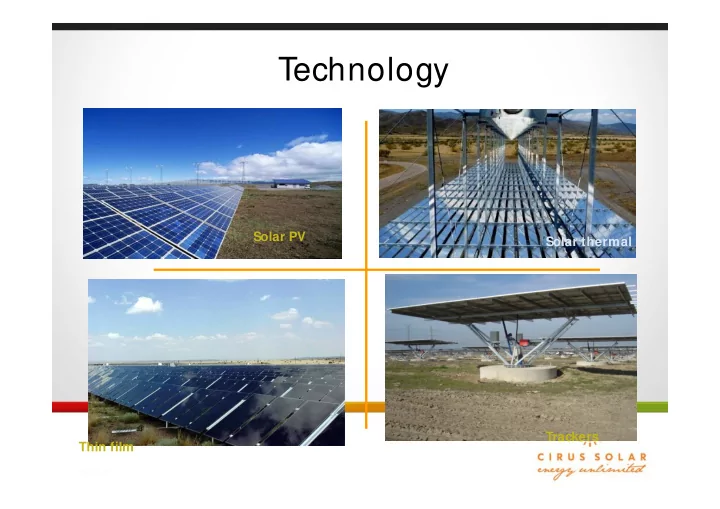

Technology • Solar PV Solar thermal Trackers Thin film

SOLAR PROJ ECT REFERENCES

Team with Execution Experience Client Volume (M W) State Client 1 25 Gujarat Client 2 8 Gujarat Gujarat Client 3 5 Client 4 1 Gujarat Client 5 25 Gujarat Client 6 5 Rajasthan Client 7 1 Rajasthan Client 8 5 Andhra Pradesh TOTAL 75

Bhoomi Puja 27 th April 2011 Site Handover 16 th M ay Rainy days July to 10 th Sept EXECUTION Speedy and Quality Execution Quick deployment of resources November 10 th 2011 28 th December 2011

25 M W Solar Power Plant Turnkey EPC , O&M Scope Solar PV Crystalline Technology Location Charanka, Gujarat COD 29-Dec -2011

5 M W Solar Power Plant Turnkey EPC , O&M Scope Solar PV Crystalline Technology Location Bacho, Kutch, Gujarat Commissioned on 5 th M ay 2012

8 M W Solar Power Plant Turnkey EPC , O&M Scope Solar PV Crystalline Technology Location M ithapur, Gujarat 25-Jan -2012 COD

5 M W Solar Power Plant Turnkey EPC , O&M Scope Solar PV Thinfilm Technology Location Bikanair, Rajastan COD 7-Feb -2012

Technology – Solar Power Photovoltaic Thermal Concentrated Crystalline Thin Film Parabolic trough (CPV) Amorphous M ono Solar Tower M ulti CIGS Linear Fresnel CdTe Parabolic dish

Solar PV M odules Technology:- Parabolic Trough Crystalline Thin Film CPV Solar Tower Parabolic Dish

M onthly Energy Profile:- Energy output [kWh/ M Wp] 25000 20000 15000 10000 30.0% 5000 20.0% 0 04:00 Dual Axis 06:00 08:00 Single Axis 10:00 Fixed System 12:00 14:00 16:00 18:00 12

M onthly Energy Chart:- 25000 jan feb 20000 mar apr Energy Output (kWh) may jun 15000 jul aug sep 10000 oct nov dec 5000 0 04:00 06:00 08:00 10:00 12:00 14:00 16:00 18:00 Time of day 13

Yearly Energy Profile:- Energy output [kWh/ M Wp] 250000 200000 150000 30.0% 100000 20.0% 50000 0 Dual Axis Single Axis Fixed System 14

System Schematic:- 5MWp Building Blocks Substation with Protections GRID 15

Building Block-Schematic:- Modules String Monitor/Combiner Protections Inverter Substation GRID Module Mounting Structure Local Controls Remote Monitoring Interface 16

Site Selection – Key Factors:- Irradiance Temperature Cloudy days Wind Speeds Dust Land Terrain Land area requirement Land cost Shade free area Water availability (for cleaning of PV modules) Nearby Substation (for evacuation of power) Site Accessibility 17

M eteo Station Data Available for Simulations Sno Station Advantage 1 NAS A Gives 22 year average , Software is free of cost 2 M eteo Norm Gives 10 Y ear Average data , data is measured with a scaling of 200 kms , software is available at cost , compatible with all software's for simulation 3 S wera Limited no of M eteo stations , mostly used for Europe .Data is available in the net for free of cost 4 3 Tier Gives 10 Y ear Average data . Software is available at cost , compatible with all software's for simulation * M eteo Norm data is quite accurate with the real time data

Solar PV Plant – Components • Solar PV M odules • M odule M ounting Structure • Inverters • Substation – Transformer , L T Panels , HT Panels , Cables etc • Protections – Lighting and Earthing Protections • Civil Works – Control room , Piling or Ramming • Civil works - Roads , Drains , Fencing and Foundations • Weather Station - Pyranometer s , Anemometer ,Temperature sensors , Data loggers • SCADA

Solar M odule Construction

Building Blocks

Solar PV M odules Technology:- Crystalline Tech: µc -Si Thin Film Temp. Coeff: -0.43%/ C Weight : 20kg Tech: a-Si Watts: 225Wp Temp. Coeff: -0.21%/ C Vmpp: 29.6V Impp: 7.6A Weight : 18kg efficiency: 13% Watts: 85Wp Vmpp: 87.5V Impp: 0.9A efficiency: 8% 1.2m 1.66m 0.99m 0.6m

Basic Comparison:- Thin Film Crystalline Cell Thickness 0.3 - 0.7 µm Cell Thickness 180 - 200 µm Efficiency varies from 5.5 - 12% Efficiency varies from 12 - 18% Reliability, limited track record Proven reliability Direct light preferred, but diffuse Both direct and diffuse light light can be used Temperature Coefficient Temperature Coefficient - 0.21%/ C - 0.4%/ C Land 7.5 to 10 acres Land 3.5 to 4.5 acres Not economical with tracker Tracker advantage 26

Plant pictures:- Thin Film Power Plant Crystalline Power Plant 27

Degradation • LID (Light Induced Degradation) • PID (Potential Induced Degradation) • M odule Degradation

LID (Light Induced Degradation) • M on Crystalline 0-3% • Poly Crystalline .2% • Thin Film 5-15% • CIGS/ CIS -

PID Potential Induced Degradation

PID

Key Factors to look for in PV M odules • M odule Grade ‘A’ • Positive Tolerance • Linear Degradation • PID Free M odule • STC and NOCT Data • ARC Coating • M icro Cracks / EL pictures • Fill Factor • Temperature Coefficients • Warranty

M odule M ounting Structure:- M ounting System / Structure Single Axis Dual Axis tracking Fixed System tracking System System Fixed with yearly Tracking one angle average optimal Tracking at 0 Deg automatic and angle seasonal tilt (manual) Tracking at yearly Fixed with seasonal average optimal tracking (M anual) angle Tracking at optimal angle all round the year Tracking with seasonal tilt 34

Fixed Optimal Angle

Fixed with M anual Seasonal Tilt

M odule M ounting Structure: Array Tracker 37

Dual Axis Tracker

Land requirement (Acres/ M W) and Energy Output Increase:- System Area In Acres Crystalline Silicon Thin Film Fixed 3.5 – 5.0 7.5 – 10.0 Single Axis Tracker 6.0 – 7.0 10.5 - 13.5 8.0 – 12.0 11.5 – 15.0 Dual Axis Tracker System Increase In Energy Output Crystalline Silicon Fixed 0 Seasonal Tilt 5 % Single Axis Tracker 15- 20 % 25- 30 % Dual Axis Tracker 39

Key Issues to look in Structures • Alignment • Galvanization Process • Warpage in structure • Nuts and Bolts - Rusting • Area Availability - Angle , Structure to Structure distance

Solar Inverter:- String Inverter Central Inverter 41

Solar Inverter – Basic Comparison:- String Inverter Central Inverter Range from 1kW to 20kW Range from 100kW to 1000kW Outdoor type (IP 65) Indoor (IP20) / Outdoor type (IP 65) Transformer Less With and Without Transformer Small size, easy to install by single Large size, need few technicians and technician an engineer to install Efficiency up to 97.6% Efficiency up to 98.6% 1M Wp power plant need 96 no of 1M Wp power plant require inverters of 10kW 4 # 250kW or 2 # 500kW Single Phase and 3 Phase 3 phase only Higher plant uptime Inverter capacity effected Easy field serviceable Skilled technicians required 43

Key Factors to Look in for Inverter Selection • Indoor / Outdoor Inverter • M PP Voltage range • String Sizing • Overloading on Inverter • Communication • M TBF • Track Record • Grid Code • Spares Availability • Online M onitoring

Type of Foundations • Open Foundation • Ramming • Piling Key Factors to look in Foundations • Pull Test at Site • SBC value for Foundation design • Wind speed at that location

PV System Protections:- Solar PV Array Surge Protective Devices Site Lightning Protection Earthing Inverter (built in Protections) S ~ To Substation Fused MCB Fused Disconnect Switch AC MCCB Surge Protective Devices 46

Substation :- 33KV GRID Iso Electronic Electronic Bkr Energy Meters Energy Meters Transformer Bkr HT Panel LA Iso LA LA CT PT Inverter to HT Circuit Breakers CT PT Electronic Energy Meter LA 47

Key Factors to Look in for Substation • Transformer Type – Dual Winding / Single Winding • Protection Relays like O/ C , E/ F , S/ C etc • M FM M eters for regular interval of recording data • Indoor / Outdoor • M etering Class • Fault Currents Calculations • Earthing Resistivity • Transmission Losses

Loss Calculations for Transmission Lines Sno Voltage Rating M egawatt Type of Losses per Km Conductor 1 11 KV 1 M W Weasel 0.76 % 2 11 KV 1 M W Rabbit 0.45 % 3 33 KV 5 M W Dog 0.13% 4 33 KV 5 M W Panther 0.06% 5 33 KV 10 M W Panther 0.13 % 5 132 KV 10 M W Zebra 0.02% 6 132 KV 25 M W Zebra 0.05 %

Factors Influencing Conversion Losses:- 50

Recommend

More recommend