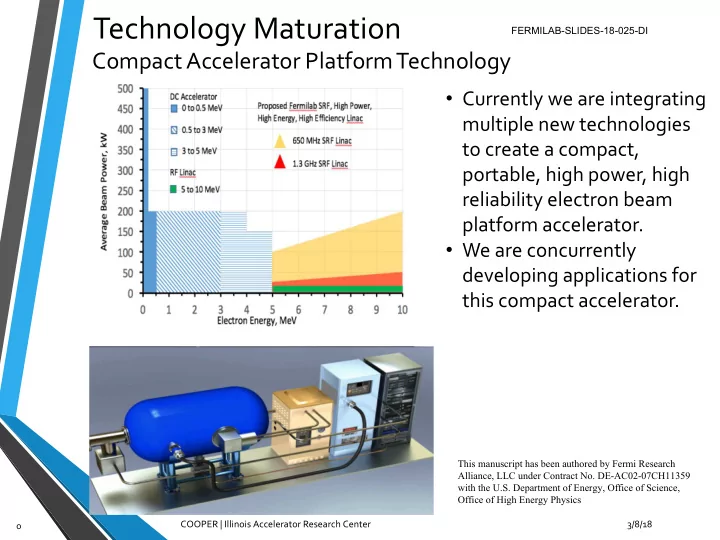

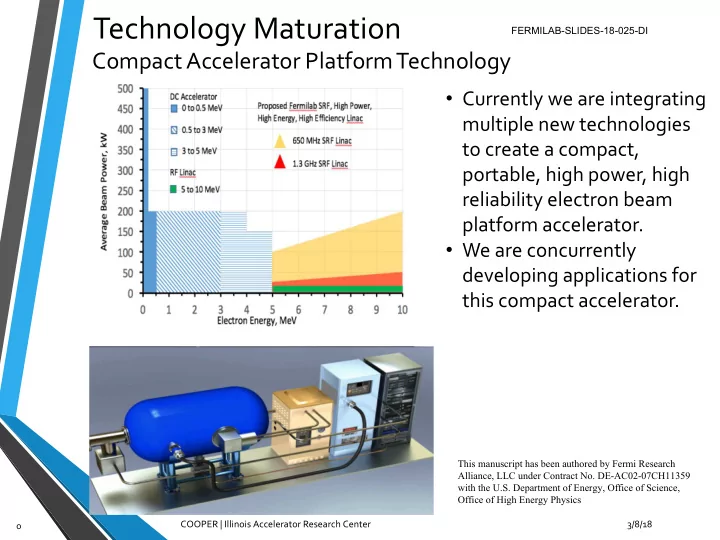

Technology Maturation FERMILAB-SLIDES-18-025-DI Compact Accelerator Platform Technology • Currently we are integrating multiple new technologies to create a compact, portable, high power, high reliability electron beam platform accelerator. • We are concurrently developing applications for this compact accelerator. This manuscript has been authored by Fermi Research Alliance, LLC under Contract No. DE-AC02-07CH11359 with the U.S. Department of Energy, Office of Science, Office of High Energy Physics COOPER | Illinois Accelerator Research Center 3/8/18 0

Application Areas • Water/Biosolids • Cargo Scanning (DNDO) • Modification of Materials (like pavement - ERDC) • Medical Sterilization(NNSA) • Driving various industrial chemistries • GTL of flare gas • Rubber • Environmental remediation, Advanced Mnfg, food treatment, surface hardening, digital electronics, mining 3/8/18 1 COOPER | Illinois Accelerator Research Center

Compact Accelerator for Pavement • High power and good penetration depth allow for rapid deployment of new pavement 1 cm • Enables use of new types of pavement materials that are more resilient to wear than asphalt 2 cm • Can be used for applications like military runways, specialty coatings, and normal roadways • Penetration depth allows for cold repairs • U.S. Patent # 9,186,645 & 9,340,931 3/8/18 COOPER | Illinois Accelerator Research Center 2

Compact Accelerator for Environmental Remediation • In several pilot programs electron accelerators have be proven to be effective at destroying toxic organic contaminates in water and soil • Typically large volumes of material are removed from contaminated areas creating a concern of secondary contamination • Key to deployment at large scale is development of high power (100’s of KW to MW class) industrial electron accelerators that are cost effective and reliable • Compact Accelerator could enable new in-situ environmental remediation or decontamination processes COOPER | Illinois Accelerator Research Center 3/8/18 3

Compact Accelerator for Crops • E-Beam treatment can improve shelf life, destroy disease causing bacteria and be used for pest control • A portable high power accelerator has the potential for saving crops in quarantined areas • Potential for large cost saving as quarantined crops are often destroyed COOPER | Illinois Accelerator Research Center 3/8/18 4

Compact Accelerator for Driving Chemistry • In the U.S. Industry consumes ~32% of end use sector • 27% of that is used in the Chemical Sector (www.eia.gov) 900 400 k • Demonstrated industrial 800 350 k effort to develop catalyst to 700 300 k increase efficiency 600 250 k • Electron Beam Driven 500 200 k 400 Chemistry largely unexplored 150 k 300 • More efficient that direct 100 k 200 heating 50 k 100 • Rubber Industry 0 k • Can remove need for some 1976 1981 1986 1991 1996 2001 2006 2011 2016 toxic initiators, cross linkers Total # US Original Catalyst Patents Total # US Original Patents patft.uspto.gov COOPER | Illinois Accelerator Research Center 3/8/18 5

US E-beam Treatment of Wastewater • *CN Kurucz et al., “The Miami electron beam research facility: a large scale waste water treatment application”, Radiat. Phys. Chem. Vol. 45, pp299-308 (1995) • High Voltage Environmental Applications, Inc., Electron Beam Technology Innovative Technology Evaluation Report - August 1997 – EPA, NRMRL • Workshop on Energy and Environmental Applications of Accelerators at ANL in June of 2015 developed language that was used in 2016 Accelerator Stewardship program. • Design 1 MW accelerator for waste water treatment COOPER | Illinois Accelerator Research Center 3/8/18 6

Why Use E-Beam for Water Treatment? Electron Beam H 2 O OH-, H+, e- aq , H 2 , H 2 O 2 • Primarily works by generating oxidizing and reducing radicals from the water • But can directly decompose contaminants as well • Removal of toxic chemicals not removed in conventional domestic water treatment • Pharmaceuticals • • Agricultural run off PCBs • • Explosives Fuel additives (MTBE) • No toxic residuals (no secondary waste generation) 100 MTBE 90 TCE 80 PCE 70 Benzene 60 Toluene E-Benzene 50 o-Xylene 40 CHCL3 30 EDB 20 NDMA 10 Atrazine 0 Simazine Experiment A *William J. Cooper, Dept. of Civil and Env. Engineering, UC, Irvine 3/8/18 COOPER | Illinois Accelerator Research Center 7

Demonstration: Municipal Waste Water • Miami, Florida treatment facility • 150 GPM • Effective in disinfecting and removing organic waste from municipal waste water • Treatment cost estimated at 1.5-2 cents/gal in 1995 *CN Kurucz et al., “The Miami electron beam research facility: a large scale waste water treatment application”, Radiat. Phys. Chem. Vol. 45, pp299-308 (1995) 3/8/18 COOPER | Illinois Accelerator Research Center 8

Demonstration: Textile Wastewater Treatment • Treatment of 1000 m 3 /day (180 gpm) of water from textile dyeing process • Showed significant decrease in TOC, COD Cr and BOD 5 (30- 40% increased removal eff.) • Based of earlier success 10,000 m 3 /day plant constructed for $4M US in 2005 • Operational cost measured to Interaction area of water and be 0.11 cents/gal. beam (beam on to the right) B Han et al., “Operation of industrial-scale electron beam wastewater treatment plant”, Rad. Phy. Chem. 81, p1475-1478 3/8/18 (2012) COOPER | Illinois Accelerator Research Center 9

Municipal Water Treatment via Compact Accelerator • Currently partnered SUN-TIMES GRAPHIC BY GREG GOOD Deep Tunnel Street River 1 Sewers from 125 e & Storm municipalities, including Intercepting Intercepting their offices, homes, with Metropolitan o reclamation plant factories and businesses, 11 BIOSOLIDS DRYING AREA empty into seven wastewater treatment After the solids leave the last centrifuge they have a soil- plants in Cook County. like texture. They still have a water content of 75% and s approximately 320 feet below the need further treatment. They are transported by train Water Reclamation face and as wide as 33 feet diameter. to the Lawndale Avenue Solids Management Area. The biosolids are spread out so the water can evaporate ending the process with 60%-70% solids. They are ARSE SCREENS then used for farms, landfill District of Chicago covers, golf courses, iminary treatment) Biosolids Biosolids highway shoulders, Screens remove large 9 Combined etc. – trash, wood, Water Water Sewer etc. – that could evaporation evaporation Systems 10 damage pumps. CENTRIFUGES CENTRIFUGES Solids are brok • Stickney plant, largest micro-organisms, producing gas in the process. The gas Deep heats the digester to 95 Tunnel degrees, Sewage for the microorganisms. to plant Water in the world (1.2 Billion SOLIDS TREATMENT returned to wastewater 8 CENTRIFUGES TREATMENT PROCESS WASTEWATER PROCESS treatment They rapidl to extracts more gal/day) liquid from the solids. To landfill CONCENTRATION TANKS Solids to solid PUMPS treatment 7 • Incoming water is a fuel process 3 AERATED GRIT TANKS Micro-organisms (Preliminary treatment) are returned to the source not just waste These use air bubbles keep lighter activated sludge tanks to continue materials suspended while grit, working sand and gravel sink to the bottom. Once the large material is on the bottom, a conveyor shovels it into a drain. What is collected is taken • Goal of net zero energy to a landfill. operation 4 PRIMARY SETTLING TANKS (Primary treatment) Here, solids settle to the • Desire to recover nitrates bottom. Fats and oils float to the top. A revolving 5 ACTIVATED SLUDGE conveyor with slats skim off AERATION TANKS the floating fats and oils and and phosphates • Biosolids can be sold as fertilizer • Treat 2MGD with 1 MW of total power , treat at Thickened WAS stage (5% solids before anaerobic digester) 3/8/18 10 COOPER | Illinois Accelerator Research Center

and Demonstration (A2D2) - Accelerator for Application Development • We are integrating multiple new technologies to create a compact, portable, high-power electron beam platform accelerator. • Electron-beam application development must be done because of the new application areas that the Compact Accelerator enables A2D2 allows for precise control of development work so that the beam, beam • sample interaction and analytical data taken can be changed as needed 3/8/18 COOPER | Illinois Accelerator Research Center 11

A2D2 Beam Info Collimator Positi Beam Distance (Fully Open) on Diameter, from cm Collimator, cm Position 1 1 4.8 63 2 5.7 75 Position 2 3 7.1 93 Position 3 4 10.3 135 5 12.6 165 Setting Power, Dose kW Rate, kGy/kg-s Position 1 0.22 0.22 4 2 0.43 0.43 3 0.65 0.65 4 0.87 0.87 Position 5 5 1.08 1.08 6 1.3 1.3 3/8/18 COOPER | Illinois Accelerator Research Center 12

Dose Distribution 9MeV Electron in Water, Rock (Density 3.75) 1.00E+02 9.00E+01 8.00E+01 7.00E+01 % Depth-Dose 6.00E+01 5.00E+01 4.00E+01 Water Water 3.00E+01 Greywacke Rock 2.00E+01 1.00E+01 0.00E+00 0 10 20 30 40 50 60 Distance (mm) 3/8/18 COOPER | Illinois Accelerator Research Center 13

Recommend

More recommend