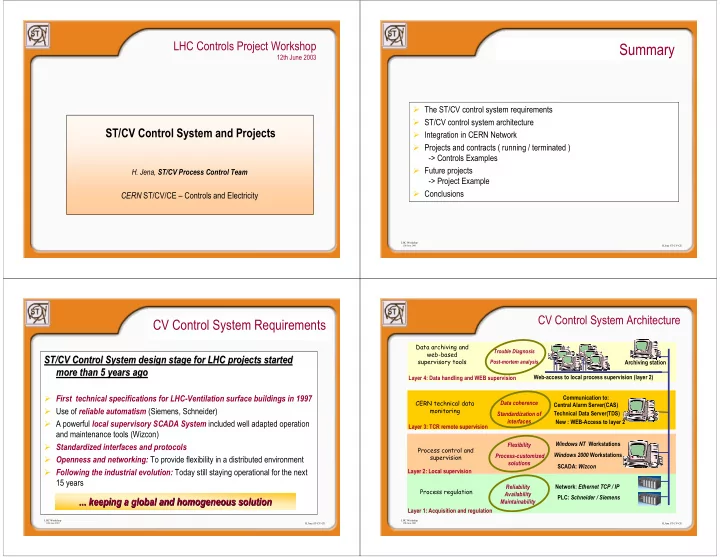

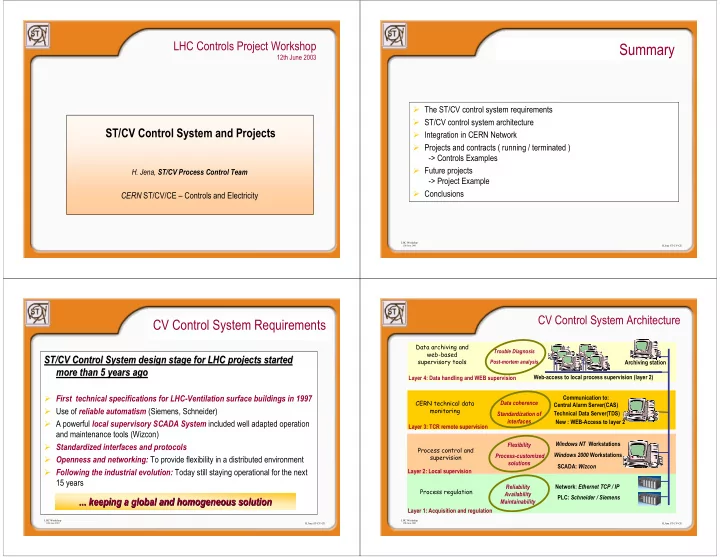

LHC Controls Project Workshop Summary 12th June 2003 � The ST/CV control system requirements � ST/CV control system architecture ST/CV Control System and Projects � Integration in CERN Network � Projects and contracts ( running / terminated ) -> Controls Examples � Future projects H. Jena, ST/CV Process Control Team -> Project Example � Conclusions CERN ST/CV/CE – Controls and Electricity LHC Workshop 12th June 2003 H.Jena ST-CV-CE CV Control System Architecture CV Control System Requirements Data archiving and Trouble Diagnosis web-based ST/CV Control System design stage for LHC projects started ST/CV Control System design stage for LHC projects started supervisory tools Post-mortem analysis Archiving station more than 5 years ago more than 5 years ago Web-access to local process supervision (layer 2) Layer 4: Data handling and WEB supervision � First technical specifications for LHC-Ventilation surface buildings in 1997 Communication to: CERN technical data Data coherence Central Alarm Server(CAS) � Use of reliable automatism (Siemens, Schneider) monitoring Technical Data Server(TDS) Standardization of interfaces � A powerful local supervisory SCADA System included well adapted operation New : WEB-Access to layer 2 Layer 3: TCR remote supervision and maintenance tools (Wizcon) Windows NT Workstations � Standardized interfaces and protocols Flexibility Process control and Windows 2000 Workstations Process-customized supervision � Openness and networking: To provide flexibility in a distributed environment solutions SCADA: Wizcon � Following the industrial evolution: Today still staying operational for the next Layer 2: Local supervision 15 years Reliability Network: Ethernet TCP / IP Process regulation Availability PLC: Schneider / Siemens ... keeping a global and homogeneous solution keeping a global and homogeneous solution ... Maintainability Layer 1: Acquisition and regulation LHC Workshop LHC Workshop H.Jena ST-CV-CE H.Jena ST-CV-CE 12th June 2003 12th June 2003

Integration in CERN Network Topologie Ethernet Services Point 4 Adaptateur FO/TP Twisted Pair Star-Point Liaison 2 x RJ 45 fibre optic Default gateway : 128.142.36.1 réseau Subnet Mask : de 255.255.252.0 UOWC 453 contrôle SR4 - Bat. 2475 UIAN 482 ventsh4 : 128.142.37.43 (station 1) SH 4 - Bat. 2484 Adaptateur FO/TP 2 x RJ 45 10 Base - T (RJ 45) Adaptateur FO/TP Twisted Pair 2 x RJ 45 Supervision Wizcon SCADA gtcvent4 : 128.142.37.48 UOWC 463 UIAN 432 SU 4 - Bat. 2480 Cabine de Supervision ventshm4: 128.142.37.42 (station 3) SHM 4 - Bat. 3477 ST/CV Projects and Contracts F 310: Chilled water production: (running and terminated) Schneider Redundancy Solution � F - 292 New pumping stations for LHC experimental points 1 & 5 (2002) � F - 300 Air conditioning of new LHC surface buildings (1999-2004) � F - 310 Chilled water production for LHC experimental points 1 & 5 (2003) � F - 405 Air handling installations for two experimental areas ATLAS / CMS (2004) � F - 480 Supply and installation of air-conditioning for the SCX 1 building (2004) � F - 472 Hydraulic, electrical and control modifications of LEP water cooling (2004) � F - 478 Supply and installation of underground cooling plants for ATLAS (2003) � CA-1281377 Ventilation of ALICE Control room (2003) � CD-1000869 Supply and installation air extraction for TI2 and TI8 injection tunnels (2003) � CD-1000931 Demineralised water circuits for CMS surface tests (2003) Examples for some projects (PLC configuration and SCADA Mimic Diagrams) ... LHC Workshop H.Jena ST-CV-CE 12th June 2003

WIZCON application F- 472 Hydraulic LHC Cooling Towers Point 8 WIZCON application F300 Ventilation LHC surface buildings WIZCON application F- 472 Hydraulic LHC WIZCON - WEB Cooling Towers Point 8 F- 472 Hydraulic LHC Cooling Towers Point 8 WIZCON - WEB application conform to UMMI mimic diagrams TCR

LHC Ventilation – Process Controle Future ST/CV Projects Migration ( LEP -> LHC ) U O W C 3 1 5 S Z UIAO 305 U 3 3 R Z 3 3 P o in t 3 3 P Z 3 3 U O W C 3 1 0 Point 3 Point 3 U J 3 3 UIAC 3 03 � 120 PLCs U J 3 2 T Z 3 2 S ta r P o in t Master S7-400 U O W C 3 0 1 U O W C 3 02 UIAO 302 UIAO 303 � CNGS and Hadron Stop ventilation S (Siemens S5 -> S7) U 3 S D 3 2 S R 3 2 P M 3 2 � CNGS cooling S E 3 2 � 20.000 I/O points to P o in t 3 2 re-program SUPPLY AIR SUPPLY AIR EXTRACT AIR EXTRACT AIR � Upgrade of Clean and Waste Water Systems of LHC � Communication changes H U B O 2 2 8 I U A U O W C 2 1 5 � Cooling of Dump Quench Resistors S u p e rv is io n W iz c o n H U B H 2 U O W C 2 1 1 2 / S A I U S G 2 U H U O W C 2 10 N 2 1 0 S U I E A 2 U O W C 2 1 2 U O W C 2 01 M a ste r S 7 - 4 0 0 0 2 U SD 2 I A O 2 U O W C 2 20 (Sinec L1, MIL1553-Bus U O W C 2 03 8 0 U I A UIAO 202 SU X 2/SX 2 O 2 0 9 U O W C 2 04 U I A N U O W C 2 06 UIAO 204 0 2 4 U O W C 2 05 UIAO 205 UIAO 207 U O W C 2 0 2 UIAO 206 SU 2 Star � Air-Conditioning in SCX5 and UX85 Point UIAO 203 change to Ethernet) S R2 S X L 2 S E 2 S F 2 U O W C 2 26 U O W C 2 25 S A 2 P M 2 5 UIAO 215 UIAC 204 � Air-Conditioning of Racks in SDX1 U W 2 5 U S 2 5 M a s te r S 7 - 3 0 0 Point 2 H U B Point 2 R E 3 2 H U B M a ste r S 7 -3 0 0 U X 2 5 P X 2 4 R E 2 8 EXTRACT AIR EXTRACT AIR � CMS Cooling Plants M as te r S 7 -3 0 0 R E 2 2 H U B p o m p sf1 -1 : 1 2 8 .1 4 2 .3 7 .1 1 p o m p sf1 -2 : 1 2 8.14 2 .3 7.1 2 H U B M a s te r S 7 -3 0 0 U O W C 1 0 1 U O W C 1 10 g tcp o m p sf1 : 1 2 8 .1 4 2 .3 7 .1 3 U O W C 1 03 � New operating modes U O W C 1 04 UIAO 102 H U B A 1 1 O 0 UIAO 103 � Renewal of PM 32 Pumping Stations Control System I U U O W C 1 05 R E 1 8 UIAO 104 M a s ter S 7 -4 0 0 UIAO 105 S u p erv isio n W iz c o n S u p erv isio n W iz c o n H U B 0 1 2 8 1 - U S S F 1 S tar P o in t U O W C 1 1 0 5 7 UIAN 101 1 2 R 1 - S 1 5 6 SD 1 S E 1 H U B U I A O � Integration of injection tunnels � LHC Ventilation – Process Controle Migration ( LEP -> LHC ) T u o SX 1 - 3185 r s B UIAO 175 A 6 H U B 1 X D SH 1 - 3184 S B A 6 H U B 1 --> some details ... S C X P M 1 5 _ ._._._ X 1 P X 1 6 U S U O W C 1 2 1 U O W C 1 81 � Integration of experimental areas UIAO 192 H U B P X 1 4 1 SG X1 - 3170 C A U I Y S 1 5 0 U I C A 6 0 1 P X 1 5 U S 1 5 Point 1 Point 1 U X 1 5 � Interactions over LHC points U S A 1 5 LHC Workshop 12th June 2003 H.Jena ST-CV-CE Conclusions � The control of cooling or ventilation processes can be achieved without considering specific solutions and by using a fully Industrial SCADA-based control architecture . � The retained solution provides a high process control precision . � The reusability of the well-proven solutions results in safer control systems: better reliability and maintainability of the process. � A global vision of the cooling and ventilation facilities allows to achieve the required levels of flexibility, coherence and homogeneity in order to assure the follow-up of the technical evolution . LHC Workshop H.Jena ST-CV-CE 12th June 2003

Recommend

More recommend