SNAME T&R Bulletin 6-1 & IMO MEPC.1/Circular 677: Guide to Diagnosing Contaminants in Oily Bilge Water to Maintain, Operate and Troubleshoot Oily Wastewater Treatment Systems Bruce Russell, Chair SNAME T&R Environmental Engineering Committee Developed by Society of Naval Architects and Marine Engineers Technical and Research Committee Panel EC-3 on Oily Wastewater and Bilge Water Panel chairs: Haluk Alper, President, Mycelx Technologies Corporation Bruce A. Russell, Managing Director, JS&A Environmental Services, Inc. Contributing panel members: Brian M. Ackerman, Chief Engineer Chris Deschenes, Marine Engineer, OSG Ship Management Ken Olsen, Senior Marine Casualty Analyst, USCG Hendrik F. van Hemmen, Vice President, Martin, Ottaway, van Hemmen & Dolan, Inc. 1

A New Way to Manage Bilge Water • Are your OWSs working as efficiently as they should? • Are your crews frustrated in operating their OWS? • Are your ships unable to consistently operate with OWS discharge below 15ppm? • Are coalescing filters being replaced prematurely? • Are you spending more on shore disposal and OWS M&O than you would like? IMO MEPC.1/ Circular 677 is new way to think about OWS and bilge water management. 2

IMO MEPC.1/ Circular 677 Circular 677 provides the foundation for the development of bilge water contaminant identification skills along with diagnostic and bilge water treatment systems troubleshooting techniques to prevent and remedy many types of oily bilge water system failures. In addition: • A range of likely shipboard sources of contamination are identified. • Simple to administer tests for ships crew to perform to identify contaminants. • Recommended preventive measures are provided. • Recommended corrective or remedial actions are provided. 3

Why be Concerned with Contaminants in Bilge Water? Newer oil content meters (OCM) are built to International Maritime Organization (IMO) standard MEPC 107(49). They are specifically designed to detect oil emulsions particles and prevent their discharge. A design limitation in most oil content meters is the limited capability to discriminate between oil and some non-oil particles. Older MEPC 60(33) OCM are poor at detecting oil emulsions and do not discriminate between oily particles and other particles. Newer MEPC 107(49) meters are more finely tuned to detect oily emulsions and iron oxide particles; however there are still limited in their ability to detect some particles and non-oily emulsions (e.g., soaps, solvents & detergents). When there is a heavy particulate load in bilge water, oil content meters can often prevent the discharge of processed bilge water. Some of these contaminants can foul the inner workings of an OWS: e.g., coalescing filters and ultra-filtration elements. Excess water will make the OWS work harder and increase M&O costs. Determining what contaminants, particulates, and particulate and emulsion forming chemicals are present in the bilge is essential. 4

Sources of Contamination in a Typical Vessel 1. Diesel engine after coolers (clean water) 2. Sludge from decanting / bottom draining storage and sludge tanks. Lube oil and fuel oil purification (oily water) 4. Fuel oil storage and settling tanks (oily water) 5. Lube oil and fuel oil filtration (oil) 6. Machinery leakages 7. Condensate from air compressors and compressed air systems 8. Diesel engine piston stuffing box leakages and piston underside blow-down (slow-speed diesels only) 9. Boiler water / condensate drains (different than piston cooling water because these include other types of chemicals (e.g., solvents), causing different concerns) 10. Equipment and engine room washing 11. Economizer water washing (soot and solvents) 12. Seawater / freshwater cooling (a potential source of biological contaminants) 13. Firefighting foam 14. Water treatment chemicals 15. Engine coolant 16. Grey water drains (soaps, detergents, biological detritus, and solvents 17. Sanitary system leaks and overflows (water and biological detritus) 18. Air conditioning and refrigeration condensate 5

It is highly recommended that ship owner’s, port engineers / company superintendents, and chief engineers develop a similar flow diagram for the source(s) of bilge water contaminants for each ship in the company fleet. 6

Organization of the Guide • Describes how to diagnose the presence of contaminants using a trouble shooting decision tree and a six point diagnostic process found in six Annexes. • It also describes chemical and physical analytical techniques used in the diagnostic processes. • Last, the Guide describes and provides recommended preventive and remedial or corrective measures. 7

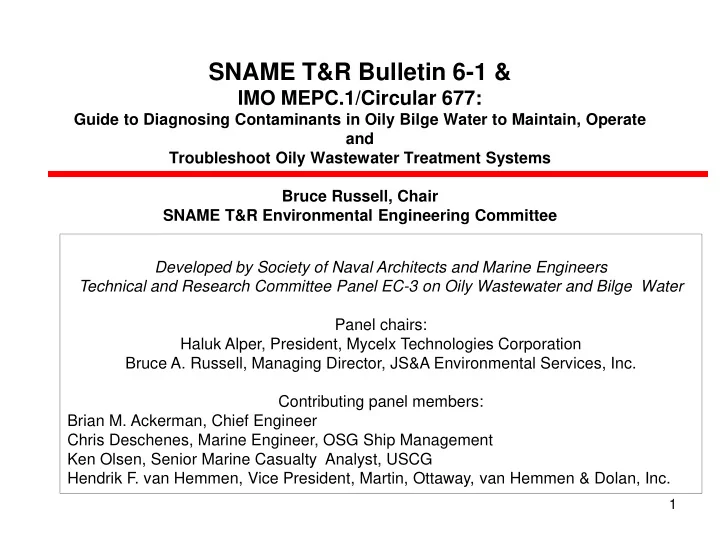

START Leg egen end IM IMO M MEP EPC.1/ C Circul ular 6 677 Diagn D agnost stic / / T Troublesh eshooting D g Dec ecisi sion T Tree ee Per erform c clea ean water er f flush sh o on Quest Qu estion the OC e OCM p per er instructions OCM is is f fault lty Test est Possi ssible C e Causes: ses: Perman anent f film o on NO NO YES YE optic ical c l cell ll D Does t es the OC e OCM r rea ead va value 0 e 0 OCM i M is w working Air bu bubbl bbles Resu esult with c th clean w n wate ter? r? Elect ctronics cs Calib libratio ion Enga gage ge Refer t to A o Appe ppendi dix I I & & Bilg ilge Annex 1 x 1 Correc ective ve Un Unit it Mea easu sure Colle llect B Bilg ilge O OWS e efflu luent in in Bilg ilge Un Unit it is is a c a clear ar, t , tal all, an , and n nar arrow working glass c ss container er w with n no so soap resi esidue YE YES Is it it O Oil? il? NO NO Is t I the O OCM CM r readi ding > > 1 15 ppm ppm Let et t the sa e sample si e sit f for 1 1 h hour To c T che heck i k if the the 1 15 p ppm constantly ly d durin ing B Bilg ilge O OWS Chec eck f for vi visi sible sh e sheen een o or o oil readi ding i is du due t to oi o oil operation ope on? laye yer o r on the n the s surf rface o of the the water s samp mple Note te the the c clari rity o ty of the the w wate ter Oi Oil i is n s not p presen esent as c clou oudy dy, c clear, or or w with c col olor or Refer t to A o Appe ppendi dix I II No o oil is il is v vis isib ible le a and No o oil is il is v vis isib ible le a and Oil is il is v vis isib ible le a and t the No o oil is il is v vis isib ible le a and t the Oil is il is v vis isib ible le a and t the water er i is c s clea ear b but water er i is c s clea ear water is is c clo loudy water is is c clo loudy water er i is c s clea ear discol di olor ored Turbid idit ity-causin ing mic icrobia ial d l detrit itus has p s prec ecipitated ed What i is c caus using cloudiness? ess? The h higher O OCM r M read ading Refer t to A Annex 4 x 4 The h higher O OCM r M read ading Oil i Oi is p s presen esent Contamin inatio ion is is o oil il is du due t to s o sol olubl ble is du due t to s o sol olubl ble Dec ecrea ease F se Flow det eter ergen ents o s or d deg egrea easer sers det eter ergen ents o s or d deg egrea easer sers Refer t to A Annex 6 x 6 Add 2 dd 2 dr drops ops of of s sulfuric Flush w h with ho th hot NO NO aci cid p per 5 50cc s cc sample water er Refer t to A Appendix I x II an and Let et t the sa e sample si e sit f for 1 15 Refer t to A Annex 5 x 5 Annex 2 x 2 mi minut utes Resi esidue m e most st l likel ely Refer t to A o Appe ppendi dix I II detergent o or o other n non- Acquire 5 50mL vola latile ile a alk lkalin line m materia ial Is t s ther ere a e a r red eduction/ sample; sa e; elim limin inatio ion o of c colo lor Add a dd a pi pinch of of The he hi highe her O r OCM Refer t to A o Appe ppendi dix I II & & YE YES wit ithin in 5 5 m min inutes a and is is citric a ci c aci cid rea eading i is d s due t e to NO NO Soot i is p s presen esent Annex 2 x 2 Has c s cloudiness r ess red educed ed? ther ere o e outgassi ssing (approxima mately particul ulates/ Rouge i e is p s presen esent .2 .2 t to .5 .5 g gram ams) bio iolo logic icals ls Refer t to A o Appe ppendi dix I II & & Refer t to A Annex 4 x 4 Annex 3 x 3 YES YE Cloudiness h ess has r s red educed ed Oil is il is e emuls lsif ifie ied Refer t to A Annex 3 x 3 8

The Decision Tree • A diagnostic decision tree for bilge water treatment systems operating in the full range of shipboard environments is provided for use in troubleshooting common system problems. • The decision tree is annotated and includes detailed diagnostic techniques and recommended remedial or corrective measures for both acute and chronic conditions. • Detailed techniques and recommendations provided in Appendices (theory) and Annexes (application of specific techniques and recommended measures). • The decision tree is designed to be used by shipboard engineers (from the "4th engineer“ to the Chief Engineer) and shore- side technical support. 9

Recommend

More recommend