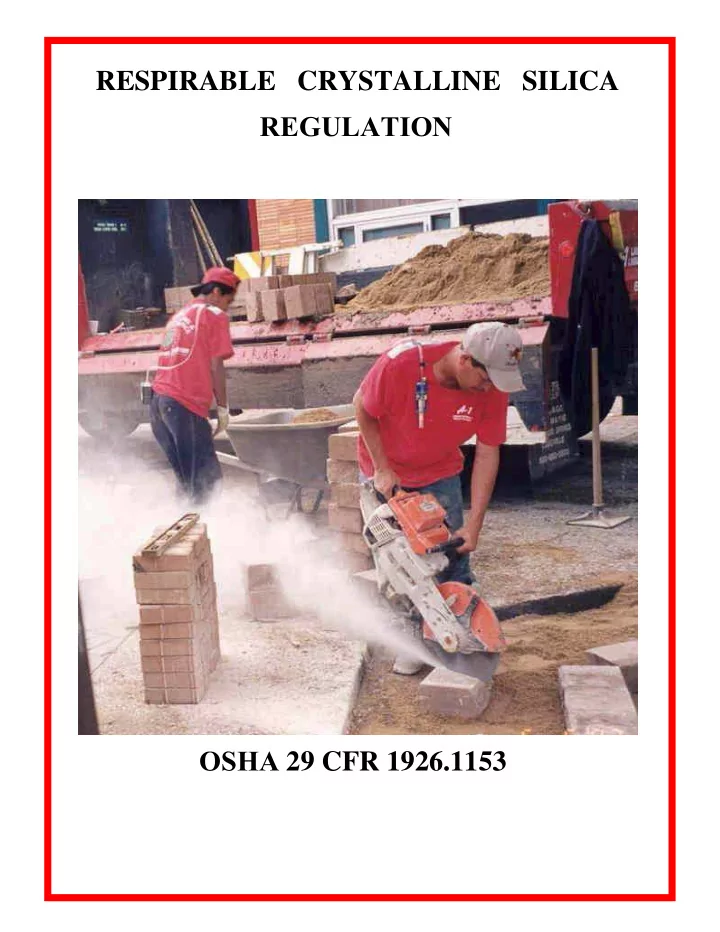

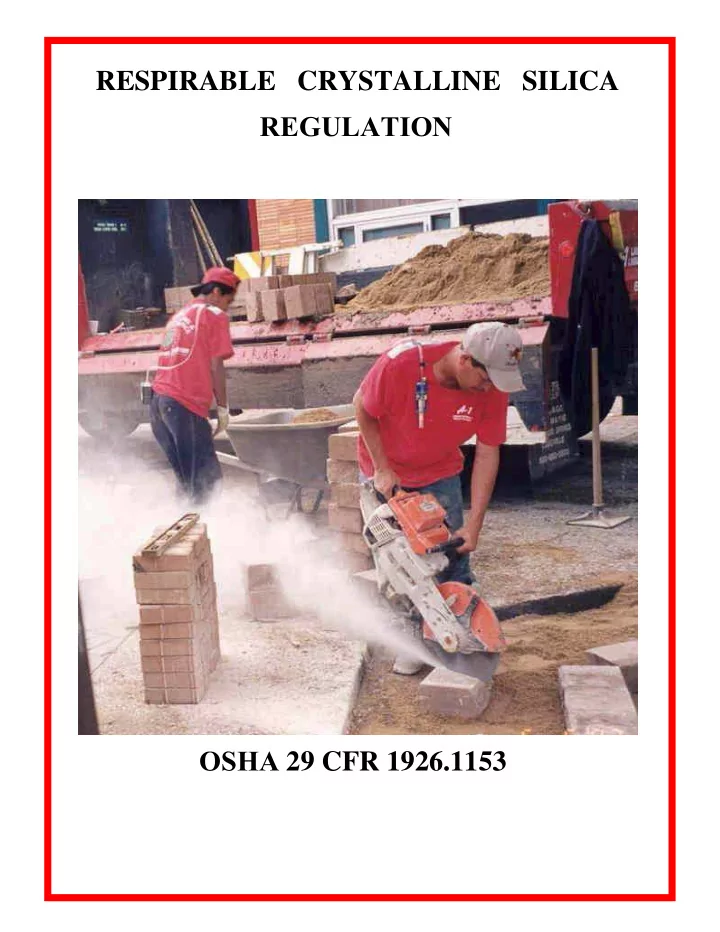

RESPIRABLE CRYSTALLINE SILICA REGULATION OSHA 29 CFR 1926.1153

OVERVIEW

TERMS and OBJECTIVES FOUND in the NEW SILICA STANDARD OBJECTIVE The new Silica Standard requires employers to; - Consult Table 1 , - Use Engineering Controls in Conjunction with Work Practices , - Use Respiratory Equipment when the exposure limits are not reduced to the required levels, and - The employer shall produce a Written Exposure Control Plan . AIR S A MPLING per OSHA APPENDIX A Employee exposure to silica shall be reliably measured using the sampling and analytical methods found in the Silica Regulation, Appendix A. PERMISSABLE EXPOSURE LIMIT (PEL) A Permissible Exposure Limit is the maximum amount or concentration of a chemical that a worker may be exposed to under OSHA regulations. TIME WEIGHTED AVERAGE (TWA) A Time Weighted Average is the average exposure over eight hours. ACTION LEVEL Action level means a concentration of airborne respirable crystalline silica of 25 μg/m3 , calculated as an 8-hour TWA. ASSIGNED PROTECTIVE FACTORS ( APF ) Assigned Protection Factor means the workplace level of respiratory protection that a respirator or class of respirators is expected to provide to employees when the employer implements a continuing, effective respiratory protection program as specified by the OSHA Standard. ENGINEERING CONTROLS used in CONJUCTION WITH WORK PRACTICES OSHA’s longstanding policy is that Engineering Controls and Work Practice Controls must be the primary means used to reduce employee exposure to toxic chemicals…respiratory protection is required to be used when engineering or work practice controls are infeasible, insufficient, or while said controls are being implemented. RESPIRATORY PROTECTION ( N95 MASK ) Respiratory Protection shall be used only when Engineering and Work Practice Controls cannot adequately lower the Exposure Level. ( Note: An extensive Respiratory Plan, including Fit Testing, and Medical Evaluation is required for respirators other than the N95 Mask. ) WRITTEN EXPOSURE CONTROL PLAN Requires employers to; - Provide Engineering Controls such as Water, Vacuum , or Ventilation, - Develop Work Practices such as limiting the amount of time the employee is exposed, - Provide Respirators when engineering controls and Work Practices cannot adequately lower the employee exposure, - Mandatory Medical Evaluation for construction employees using respirators 30 days, or more, annually, and - Develop a Written Exposure Control Plan , specific to the trade and work activities. TABLE 1 - GRAPHIC VERSION The table provides compliance options for 18 typical construction tasks that produce high employee exposure to silica dust. Employers that fully and properly implement the controls are not required to measure respiratory crystalline silica exposures. EQUIPMENT Water, Vacuum and Ventiation.

COMPLIANCE DATES Significant dates are; June 23, 2016 Regulation shall become effective Sept 23, 2017* All requirements except methods of sample analysis June 23, 2018. Requirements for methods of sample analysis SCOPE This section applies to all occupational exposures to respirable crystalline silica in construction work, except where employee exposure will remain below 25 micrograms per cubic meter of air as an 8-hour time-weighted average under any foreseeable conditions. DEFINITIONS Time Weighted Average - A time weighted average (TWA) is the average exposure within the workplace to any hazardous contaminant or agent using the baseline of an 8 hour per day or 40 hours per week work schedule. The TWA reflects the maximum average exposure to such hazardous contaminants to which workers may be exposed without experiencing significant adverse health effects over the standardized work period. The TWA is expressed in units of parts per million (ppm). Permissible Exposure Limit - Permissible exposure limit (PEL) is the legal limit in the U.S. for maximum concentration of any chemical in the air to which a worker may be exposed continuously for eight hours without any danger to health and safety. Engineering Controls - Engineering controls are physical changes to the work area or process that effectively minimize a worker's exposure to hazards Competent Person - Competent Person means one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them. CONTROL METHODS For each employee engaged in a task identified on T able 1, the employer shall fully and properly implement; Engineering Controls, Work Practices, and Respiratory Protection _______________________________________________________________________________ * Per OSHA memorandum issued April 6 th 2017, Compliance extended from June 23 rd to Sept 23 rd 2017

ESTABLISHING EXPOSURE The employer shall assess the 8-hour TWA exposure for each employee on the basis of any combination of air monitoring data or objective data sufficient to accurately characterize employee exposures to respirable crystalline silica. SCHEDULED MONITORING The employer shall perform initial monitoring to assess the 8-hour TWA exposure for each employee on the basis of one or more personal breathing zone air samples that reflect the exposures of employees on each shift, for each job classification, in each work area. Where several employees perform the same tasks on the same shift and in the same work area, the employer may sample a representative fraction of these employees in order to meet this requirement. In representative sampling, the employer shall sample the employee(s) who are expected to have the highest exposure to respirable crystalline silica. EMPLOYEE NOTIFICATION Within five working days after completing an exposure assessment, the employer shall individually notify each affected employee in writing of the results of that assessment or post the results in an appropriate location accessible to all affected employees Whenever an exposure assessment indicates that employee exposure is above the PEL, the employer shall describe in the written notification the corrective action being taken to reduce employee exposure to or below the PEL COMPLIANCE METHODS The employer shall use engineering and work practice controls to reduce and maintain employee exposure to respirable crystalline silica to or below the PEL, unless the employer can demonstrate that such controls are not feasible. Wherever such feasible engineering and work practice controls are not sufficient to reduce employee exposure to or below the PEL, the employer shall nonetheless use them to reduce employee exposure to the lowest feasible level and shall supplement them with the use of respiratory protection. USE OF ENCLOSED CABINET OR BOOTH For measures implemented that include an enclosed cab or booth, ensure that; Is maintained as free as practicable from settled dust; Has door seals and closing mechanisms that work properly; Gaskets and seals that are in good condition and working properly; Is under positive pressure maintained through continuous delivery of fresh air; Has intake air that is filtered through a filter that is 95% efficient in the 0.3-10.0 μm range; Has heating and cooling capabilities.

IMPLEMENTING CONTROL MEASURES IN TABLE 1 If you comply with T able 1, you do not need to monitor for silica or comply with the PEL. When implementing the control measures specified in T able 1, each employer shall: For tasks performed indoors or in enclosed areas, provide a means of exhaust as needed to minimize the accumulation of visible airborne dust; For tasks performed using wet methods, apply water at flow rates sufficient to minimize release of visible dust; WRITTEN EXPOSURE CONTROL PLAN The employer shall establish and implement a written exposure control plan that contains at least the following elements: A description of the tasks in the workplace that involve exposure to respirable crystalline silica; A description of; Engineering Controls, Work Practices, and Respiratory Protection A description of the housekeeping measures used to limit employee exposure, A description of the procedures used to restrict access to work areas, The employer shall designate a Competent Person to make frequent and regular inspections of job sites. EMPLOYEE TRAINING The employer shall ensure that each employee covered by this section can demonstrate knowledge and understanding of the following: The health hazards associated with exposure to respirable crystalline silica; Specific tasks in the workplace that could result in exposure to respirable crystalline silica; Specific measures the employer has implemented to protect employees from exposure to respirable crystalline silica, including engineering controls, work practices, and respirators to be used; The contents of the silica regulations; The identity of the Competent Person designated by the employer; and The purpose and a description of the medical surveillance program.

TABLE 1

EQUIPMENT USE / TASK ENGINEER. CONTROL LESS THAN 4 HOURS MORE THAN 4 HOURS Use saw Stationary masonry saws equipped with integrated water delivery system that continuously feeds water to the blade. (None required) (None required) Operate and maintain tool in accordance with manufacturer’s instructions to minimize dust emissions. Use saw Handheld power saws (any blade equipped with diameter) integrated water delivery system that continuously feeds water to the blade. Operate and maintain tool in accordance with manufacturer’s instructions to minimize dust emissions: When used outdoors (None required) (APF 10 required)

Recommend

More recommend