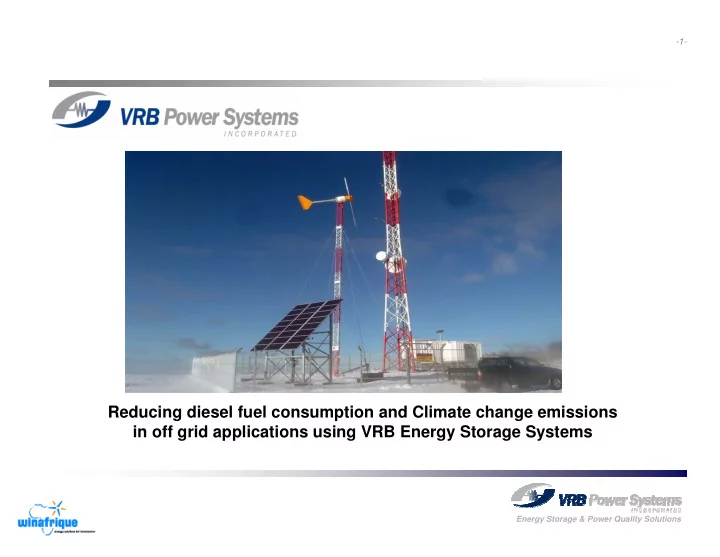

-1- Reducing diesel fuel consumption and Climate change emissions in off grid applications using VRB Energy Storage Systems Energy Storage & Power Quality Solutions

-2- The Concept • Loading of diesel engines at close to maximum improves their efficiency and use of fuel by as much as 35% • Additionally, proper loading reduces fouling and overall maintenance costs on a $/kWh generated basis. • By adding wind turbine generation to a microgrid, it is possible to reduce the use of diesel HOWEVER the amount of wind generation as a percentage of diesel generation is limited for stability reasons to about 20%. Thereafter you must provide electrical energy storage to stabilize wind power output variations. • Because wind power output is variable and because load is variable you require an energy balance or storage device to match demand to supply • If too much wind is added, you can end up with increased diesel usage simply to stabilize the grid. • Applying a VRB Energy Storage System (VRB-ESS) allows you to add significant wind up to 80% penetration and balance the grid, reduce emissions, lower fuel usage, reduce maintenance and extend diesel generator life. Energy Storage & Power Quality Solutions

-3- Diesel Engine fuel usage as a % of full load Fuel consumption in Litres per kWh as a % of Full load - (reference CAT 3516) Litres/kWh 0.45 0.40 ��������������� 0.35 0.30 0.25 0.20 0.15 0.35-.26)/.35 =25% ������������ fuel usage 0.10 improvement 0.05 0.00 100.00% 75.00% 50.00% 25.00% 10.00% Energy Storage & Power Quality Solutions

-4- Single line for VRB-ESS™ RAPS application Distribution grid n/c or utility Local loads Step up transformer 10 100 480V bus Conventional Genset 8 80 Power [kW] Power [%] 6 60 4 40 DC 1 2 = ~ Average 2 ~ 20 gensets - 2x 0 500kW VRB/ESS - 650 to Potential Wind 0 2 4 6 8 10 12 14 16 18 20 22 24 700kW 4 hours Time of day [Hrs] turbine (s) Energy Storage & Power Quality Solutions

-5- VRB Flow Battery Technology VRB Flow Battery Technology A liquid electrolyte that is separate from the electrode. • An electrochemical energy storage system operating at ambient temperatures • Reversible fuel cell – reduction and oxidation of single unique element: Vanadium • No cross contamination as with other storage systems. Electrolyte never wears out – high residual value • Very low maintenance • Deep cycles (10 to 90%) >10,000 • Low self discharge – indefinite energy storage • Energy can be recovered instantaneously • Battery can recharge as fast as it discharges (1:1) • Power and Energy separately scaleable Oxidation process Reduction process V 3+ + e - � V 2+ Charge V 4+ � V 5+ + e - V 5+ + e - � V 4+ V 2+ � V 3+ + e - Discharge Energy Storage & Power Quality Solutions

-6- Vanadium as mined Energy Storage & Power Quality Solutions

VRB Technology – power and energy are modular and separately -7- scaleable • 5kW – 10MW • VRB controls worldwide patents* (*excludes Japan and Australia) Energy Storage & Power Quality Solutions

-8- What is required – what is the process? Where can this concept be applied – what are the selection criteria • Determination of site specific Wind regimen (over 5m/s required) • Load factor (less than 65% required) • Load growth (must be reasonable or constant) • Where diesel costs are high • Reactive energy Var support (added value) • Local skills development for site support (required training due to access issues) • Detailed load profiles required Options • Diesel and Storage alone • Diesel and wind alone • Diesel - wind - storage combinations • High wind penetration (>20%) requires electrical energy storage of some form • Types of storage – choices. Historically only Lead acid batteries have been considered. However, only storage with the ability to deep discharge thousands of times and recharge very fast is suitable. • Model options using NREL’s HOMER software version 2.5beta Energy Storage & Power Quality Solutions

-9- Limitations of conventional storage solutions have prevented deployment of storage for cycling applications Lead Acid Battery VRB Flow Battery 5KW – 4hrs 5KW – 4hrs 25% Discharge Ideal 100% Discharge Capability 75% “unusable” Life Span – 15-30 years Charge Rate – 1:1 Cycles 100% - tens of thousands Life Span – 3-4 years Scalability – 3.5kW to 10 MW Charge Rate – 5:1 Environmentally Friendly Enviro Rating – Poor • No heavy Metals Scalability – 1W to 500kW • Indefinite Life Energy Storage & Power Quality Solutions

-10- Inside the 2MWh PacifiCorp installation in Moab Energy Storage & Power Quality Solutions

-11- Proven Technology – VRB Power • 250 kW x 8 hour VRB-ESS Grid Enhancement Project PacifiCorp, Castle Valley, Utah • 4 years successful operation • Avoided Capex of US$4m / Ability to “Peak Shave” – Payback 3-4 years Energy Storage & Power Quality Solutions

-12- Proven Technology - Sumitomo • 4 MW x 1.5 hour VRB-ESS Grid-Coupled Wind Smoothing Sapporo, Japan • One of several VRB-ESS installations in Japan Energy Storage & Power Quality Solutions

-13- Ireland – Sorne Hill – 32MW Wind Farm VRB site location 2008 Energy Storage & Power Quality Solutions

-14- Large System Performance - PacifiCorp - 96% Availability Normalised Plant Operating Hours-TD-Dec-06 1 0.8 0.6 0.4 0.2 0 5 5 5 5 5 6 6 6 6 6 6 5 5 5 5 5 5 6 6 6 6 6 6 l a 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 t - - - - - - - - - - - - - - - - - - - - - o - - b r r n l v c n b r r n l v c y u g p t y u g p t T a a p c o p c o e a u u e e a e a u u e e J J M M A O N A O N F M J A S D J F M J A S D Source: EPRI Run Time Idle Time Unplanned Downtime Planned Downtime Energy Storage & Power Quality Solutions

-15- Daily Wind Output Smoothing at J-Power • The VRB-ESS (blue line) runs continuously to smooth wind farm production (green line) • At only 20% of the wind-farm’s nameplate capacity, the VRB ESS has a significant smoothing effect to total wind-farm + battery output (red line) • The VRB-ESS intelligently recharges throughout the day so that it maintains 50% SOC Energy Storage & Power Quality Solutions

-16- 600 Daily Cycles at 6MW Peak Wind Farm Installation No other technology can economically meet this and no storage technology can technically achieve this cycling Energy Storage & Power Quality Solutions

-17- Case studies of Hybrid systems - Large • Case study 1: Canada 3MW system with HIGH wind penetration • Case Study 2: Alaska 3MW system - Base case – just diesel - Base case Plus 9% wind no battery - Base case plus VRB-ESS no wind - optimised case with 9% wind, and VRB-ESS Energy Storage & Power Quality Solutions

Case Study 1 – Canadian VRB-ESS with high wind -18- penetration • James Bay 3.3 MW diesel powered village • Simulation using wind turbines and 1.5MW x 15hr VRB-ESS to reduce fuel usage and emissions • Energy Cost dropped by 65% • ROI of over 30% / Payback 3-4years • Storage essential at 80% wind penetration • 300 similar communities in Canada alone Production Fraction Component (kWh/yr) Wind turbines 6,555,549 61% Cat 3512 3,451,548 32% Cat D398/379 5,043 0% CAT 3516 667,888 6% Total 10,680,027 100% Energy Storage & Power Quality Solutions

Case Study 1: James Bay – VRB-ESS with very high wind -19- penetration Emissions (kg/yr) Pollutant Emissions (kg/yr) with wind Carbon dioxide 11,754,766 5,285,091 Carbon monoxide 29,015 12,562 Unburned hydrocarbons 3,214 1,392 Particulate matter 2,187 947 Sulfur dioxide 23,606 10,621 Nitrogen oxides 258,903 112,094 Energy Storage & Power Quality Solutions

Case study 2. Alaska 3.5MW Diesel peak: No wind-no -20- VRB Annual electric energy production (Base Case) Production Fraction Levelised cost of energy: 0.419 $/kWh Component (kWh/yr) Cat 3512 309,036 1% Load Factor: 68.1% Cat 3516 100,900 0% Fuel Usage per year US$6.1million (@ EMD 710G 22,778,502 98% US$0.80/litre) (7.6million litres/year) Total 23,188,438 100% 20 year life, DR 6.5%, no fuel cost escalation Energy Storage & Power Quality Solutions

-21- Alaska 3.5MW diesel – low (9%) wind penetration no VRB Annual electric energy production Production Fraction Component Levelised cost of energy: 0.389 $/kWh (kWh/yr) Wind turbines 3,683,168 16% Cat 3512 1,667,687 7% Cat 3516 146,578 1% EMD 710G 18,014,788 77% Total 23,512,220 100% Energy Storage & Power Quality Solutions

-22- Alaska 3.5MW diesel – with VRB-ESS - no wind Annual electric energy production Levelised cost of energy: 0.376 $/kWh Production Fraction Component (kWh/yr) Cat 3512 2,231,235 9% Cat 3516 135,180 1% EMD 710G 21,177,232 90% Total 23,543,646 100% Energy Storage & Power Quality Solutions

Recommend

More recommend