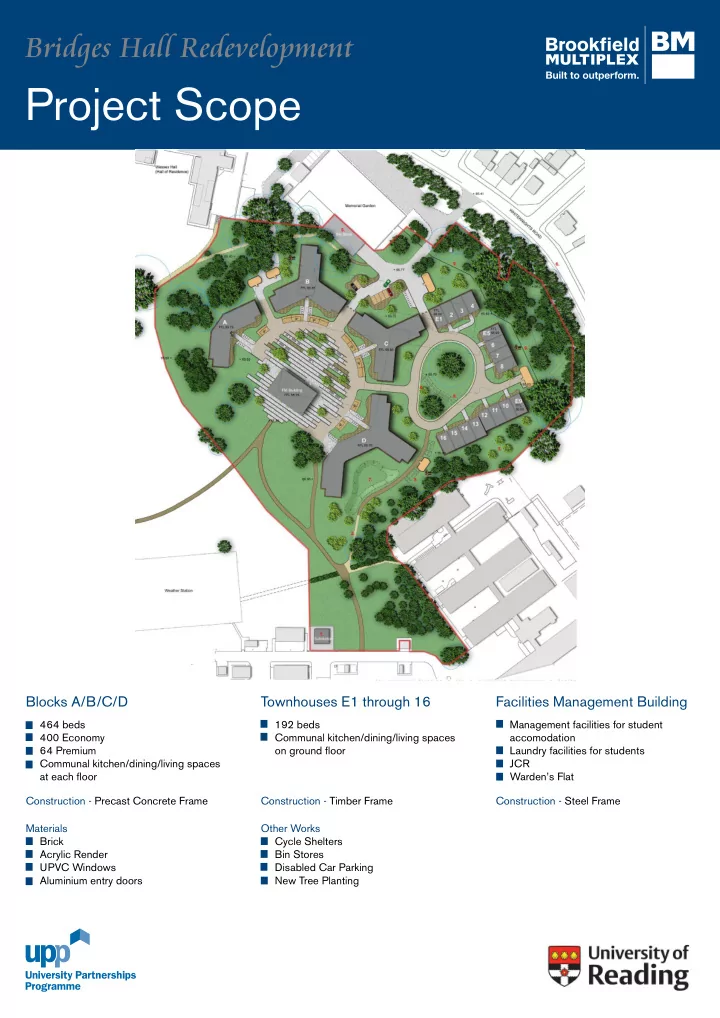

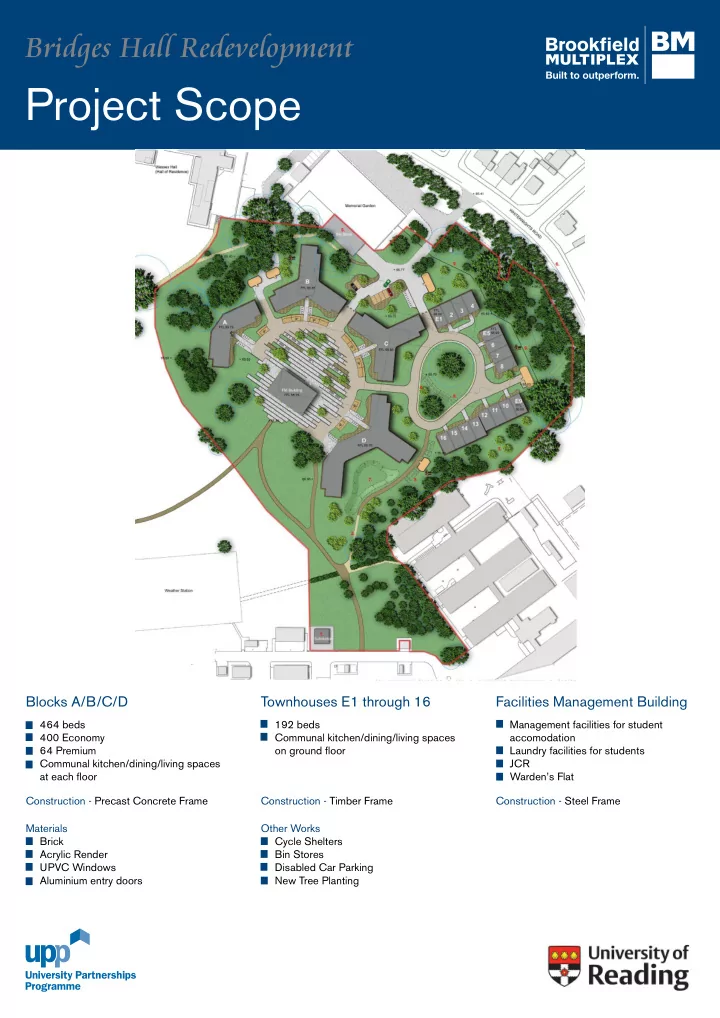

Bridges Hall Redevelopment Project Scope Blocks A/B/C/D Townhouses E1 through 16 Facilities Management Building 464 beds 192 beds Management facilities for student 400 Economy Communal kitchen/dining/living spaces accomodation 64 Premium on ground floor Laundry facilities for students Communal kitchen/dining/living spaces JCR at each floor Warden’s Flat Construction - Precast Concrete Frame Construction - Timber Frame Construction - Steel Frame Materials Other Works Brick Cycle Shelters Acrylic Render Bin Stores UPVC Windows Disabled Car Parking Aluminium entry doors New Tree Planting

Bridges Hall Redevelopment Introduction Bridges Hall Development University of Reading Sewer Pedestrian Route From Car Park to Site Bridges Hall Works Bridges Hall Site Car Park Pedestrian Route From Car Park to Site Contractor’s Car Parking & Pedestrian Route to Site The Bridges Hall redevelopment involves the demolition of the existing halls of residence and the construction of 649 new rooms in cluster flat and townhouse accommodation. The cluster flats will offer both en-suite and shared bathroom accommodation. In addition, the scheme will include an FM hub with a two bed warden’s flat and Junior Common Room, bike stores, bin stores and a new substation. The Bridges Hall redevelopment constitutes the third and final phase of the University of Reading’s ten year halls redevelopment programme to provide circa 2,500 new high quality study bedrooms and consolidate the University’s student accommodation on to its Whiteknights Campus. University Partnerships Programme (UPP) has been selected by the University as its long term partner to provide management and maintenance services across its entire student accommodation portfolio. As part of the partnership arrangement UPP will also redevelop the Bridges Hall site. UPP has selected Brookfield Multiplex as its preferred building contractor for the development. Planning consent was granted for the development by Wokingham Borough Council on 4 th April 2012. Construction is programmed to commence in mid July 2012 with practical completion being achieved in August 2014.

Bridges Hall Redevelopment Site Access Plan Bridges Hall Development University of Reading Site Compound Sewer Main Site & Delivery Holding Access Area Wessex Halls Water LEGEND Water Supply 1 Preferred Pedestrian Route to Site Tree Protection and Site Hoarding Temporary Power Supply 1 Location Site Team Assembley Point PEDESTRIAN ROUTE TO Emergency SITE FROM Escape Gate CONTRACTORS CAR PARK Temporary Access route to Sub station & Ext Works HV Cable Emergency Access Route LOGISTICS PLAN Parking: There will be No Parking permitted off site, particularly in Whiteknights Road or adjacent side streets All contractors, site operatives and construction staff will use the “Contractors Car Park” on Queens Drive (off Shinfield Road) This will be an obligation within in all Sub-Contract Terms & Conditions. Guilty parties will be reprimanded and repeat offenders removed from the project Limit Brookfield Multiplex management parking to be within site compound Personnel Access: Operatives will approach the site via the foot paths leading from the “Contractors Car Park” as indicated on the introduction board Operatives will access the site compound via a bio-metric turnstile for increased security Operatives will exit the site in the same way Deliveries: Site Compound & Delivery Direction of all site traffic and delivery vehicles will be as Holding Area indicated on the above plan Delivery vehicles will not be permitted to park/queue in Whiteknights Road or adjacent side streets There will also be facilities for a holding area for delivery vehicles within the site compound if required Deliveries will be scheduled on a strict booking in basis Delivery times will be restricted to the site hours of 0800hrs to 1800hrs Monday to Friday and 0800hrs to 1300hrs Saturdays (to be co-ordinated with peak local traffic times) Directional signage will be distributed around the campus with LORRY INGRESS AND EGRESS “No Entry” signage displayed on other adjacent entrances such as Earley Gate, to prevent inconveniencing other faculties

Bridges Hall Redevelopment Asbestos Removal The existing buildings contain asbestos which will be removed in a controlled and safe manner prior to the demolition. The works will be carried out by a specialist contractor and monitored by an asbestos consultant and Brookfield Multiplex man- agement. The asbestos will be safely removed from site in specially labelled, red airtight double bags and taken to a licensed tip. Measures that will be taken to ensure safety for the operatives removing the asbestos and to protect the environment around the site are summarised as follows:

Bridges Hall Redevelopment Asbestos Removal Enclosures for working with asbestos Typical design of a 3 stage Airlock Enclosures will be utilised on Bridges Hall throughout the asbestos removal process. The size of an enclosure depends on the size of the asbestos work area and how many people are required to work in that space. The most widely used material for enclosure walls is opaque, 1000 gauge polythene sheeting. Air Extraction Equipment (NPU) Typical design of a 3 stage Baglock Necessary to use a mechanical extract ventilation system such as a Negative Pressure Unit (NPU). This system will ensure that the airflow through any leaks in the enclosure will be inwards rather than outwards. Inside an enclosure there must be a minimum of 8 air changes per hour in order to replace the extracted air so that the ventilation of the area is regulated. This is achieved by allowing air to enter though the Decontamination Units airlocks in a controlled manner. A DCU should be on site before the works begin and the last thing to leave site All DCU’s will have a “DIRTY” and Airlocks and Baglocks “CLEAN” labelled doors All enclosures must have a means of access for personnel, plant , equipment and removal of asbestos waste. Minimum requirement - Each section of an airlock and baglock should be at least 1m x 1m x 2m (height). This is achieved by making a vertical slit in the polythene and fixing overlapping and weighted polythene sheets across the opening. The additional sheet must be placed on the side closest to the enclosure so that the air can be pulled towards the enclosure.

Bridges Hall Redevelopment Dust/Noise/Light Pollution Noise As part of the Planning Conditions the Project has restricted working hours 0800hrs to 1800hrs Monday to Friday and 0800hrs to 1300hrs Saturdays No construction noise will be permitted outside of these times. Lorries and delivery vehicles will not deliver outside these times and will not be permitted to park up early waiting to make a delivery. All Plant & Equipment will be in good working order and silenced to industry standards External Telephone bells or PA systems will not be used on the Project Examination & Revision times during 2013 & 2014 have been advised to Brookfield Multiplex by the University of Reading and we have programmed our works for “No noisy” activities during these periods We are conscious of the Day Nursery on the campus and will liaise with them as to any particular requirements with regard to quiet times. Noise will be monitored - chosen locations across the site will have noise meters to ensure the demolition noise levels are not exceeded Environmentally Friendly Mobile Crushing Operations Brookfield Multiplex has operational capacity to achieve the highest environmental requirements with the facilities to provide a varying range of mobile crushing plant and on-site recycling provisions. Incorporates latest dust suppression techniques Increases a projects recycling rates Allows for complete segregation of varying waste streams for removal/re-use on site. Dust The method of Demolition will be to dismantle the existing building piecemeal and not on mass, so as to keep dust to a minimum During the Demolition Phase the works will be constantly sprayed with water to suppress the dust Wheel Washes will be installed to prevent the adjoining streets from becoming muddy Road sweeping will be employed to ensure clean adjoining streets Water interceptor tanks are to be installed to prevent contaminated water entering the surface water system Light Pollution All site security lighting will be positioned so as not to shine in the direction of the Residential or Occupied Areas Any lighting that does prove to be an issue will be shaded or switched off outside working hours Bat relocation lighting will be employed during August, September & October this year to ensure all bats have left Bridges Hall. All lighting will be shaded to prevent glare into Residential or Occupied Areas Low level security lighting to the site hoarding will be left on over night for security reasons.

Recommend

More recommend