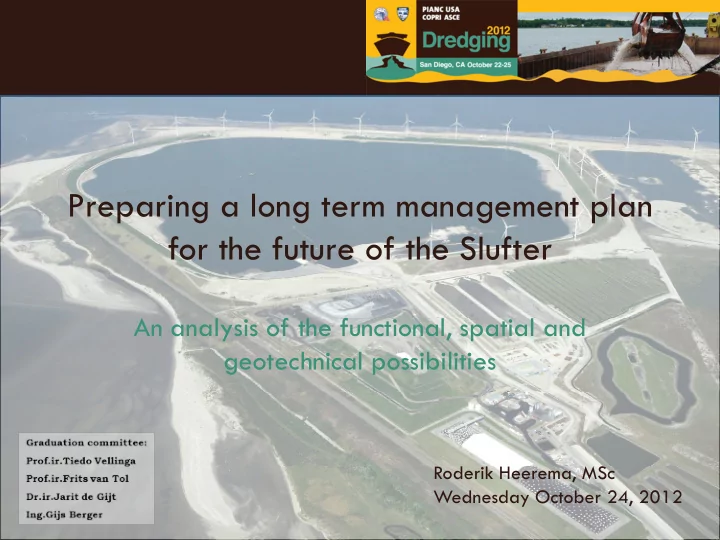

Preparing a long term management plan for the future of the Slufter An analysis of the functional, spatial and geotechnical possibilities Roderik Heerema, MSc Wednesday October 24, 2012

Content • Introduction • The Port of Rotterdam • Contaminated dredged material management in the Netherlands • The Slufter • Conclusions

Introduction

Introduction DEME

Introduction

Introduction

Introduction

The Port of Rotterdam

The Port of Rotterdam

The Port of Rotterdam • Every year: – €500 Million Turnover – 430 million tons of goods throughput – 34,000 ocean going vessels and 100,000 inland vessels – Third largest port in the world • Expanding…

The Port of Rotterdam Maasvlakte 2

Contaminated dredged material management in the Netherlands • 3 to 5 million cubic meters of contaminated material dredged yearly • Several facilities… • Total remaining storage capacity 85 million cubic meters • Enough for the next 32 years Hollandsch Diep Ijseloog The Slufter

The Slufter | CDF • Large scale Confined Disposal Facility • Built in 1987 • Storage of contaminated dredged material

The Slufter | Location

The Slufter | Dimensions 3.7 miles 1.2 miles 6km 642 acres 2km 260ha

The Slufter | Dimensions NAP +24m 52m NAP +6m Total capacity NAP +2m 150 million m 3 NAP Dredged 30m material NAP -28m 171 ft 98 ft 196 yd³

The Slufter | History • Why it was built • The “Rhine Research Project” • The Slufter through the years…

The Slufter | History

The Slufter | Today The Slufter is increasingly losing its function • Reduced supply of contaminated dredged material – Expected lifetime in 1987 was 15 years – More than 24 years later only 50% has been filled • Overcapacity • Surplus of space which is not ready for use

The Slufter | Functions

The Slufter | Functions

The Slufter A Geotechnical Challenge • Building on dredged material – Clay and silt particles – Very low bearing capacity Remaining Retaining New land storage capacity structure Dredged material

The Slufter A Geotechnical Challenge

The Slufter A Geotechnical Challenge 400m

The Slufter A Geotechnical Challenge

The Slufter A Geotechnical Challenge

The Slufter A Geotechnical Challenge The principle of dry storage 1. Remove water sheet and lower ground water level 2. Initiate a process of ripening dredged material 3. Obtain a layer with sufficient bearing capacity Ripened dredged material Dredged material

The Slufter A Geotechnical Challenge

The Slufter | Solution A long term approach – Use the incoming supply of dredged material as elevation material – Elevate until the layer has sufficient bearing capacity and develop from thereon – Lower the ring-dike – Move towards a phased dismantlement of the Slufter

2017 30ha 2022 60ha 2032 120ha

Conclusions • Accept the current situation! • Initiate dry storage! • Use the space! • Create value!

Questions?

Recommend

More recommend