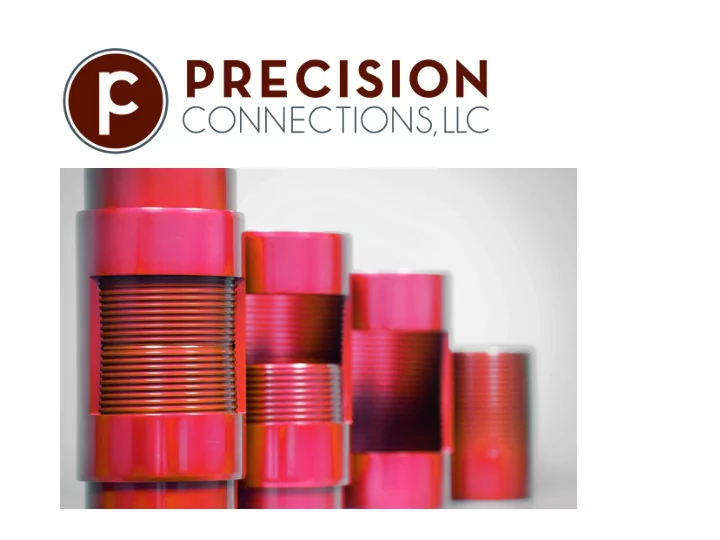

Precision Connections BK-FX Semi Premium Connection Buttress Compatible Full Size Coupling with an Integral Shoulder Designed Primarily for High Torque Frac Strings

BK-FX Features Higher Torque and Improved Sealing The BK-FX • uses a thicker coupling with a larger OD to increase strength and torque resistance. The thicker coupling can take higher frac pressures and supports thicker wall pipe with 100% matched pipe strength. It also provides more strength when utilizing high collapse or enhanced burst strength pipe. Buttress Compatible for cost savings on hangers, • float shoes, float collars, crossovers and custom tools.

• Better Buttress Sealing Modified buttress thread for tighter thread sealing and pin nose seal stabilization. BK Thread Tolerance – Minimizes API Thread Tolerance – Verified • • thread gap for better thread fit of several major insert sealing. Uses a Custom Premium manufacturers. Insert.

Better Buttress Pipe Threads for Sealing and Easy Makeup • Tighter tolerances on lead, taper, ovality and pitch diameter. • More pin nose area from OD and ID bevel design. • Aggressive de-burr for trouble free make-ups. Good Bad Black Crested Threads provide a leak path. Shiny threads seal.

Coupling Shoulder Provides a positive torque stop and improves coupling strength. Easier to make up than semi premium with less chance of a bad make up. Isolates stresses from the mill end and field end. The BK-FX will have lower coupling stresses if the connection is inadvertently over-torqued.

Fast and Consistent Shoulder Torque Installation Better • threading techniques and coupling coatings allow for a quick low cost installation. The BK-FX will run quickly, reducing the run time per well.

Strength Pin Nose to Coupling contact for high torque resistance, • higher pressure ratings, higher bending loads and higher structural compressive loading . Smooth Premium Bore with no J-Area to get hung up on. Buttress Pressure Standard Buttress allows the internal pressure to react against the thin walled coupling.

Strength A low hoop stress design reduces the chance of coupling splits and leaks from high frac pressures. Stress is kept below material yield strength. The coupling will return to its Installed original shape after the frac Stress without high residual stresses and deformations that accelerate corrosion and crack growth. Frac Stress

High RPM Fatigue Resistance from Low Stress Runout Threads The BK uses the field proven buttress thread with low stress runout threads to extend the time it can be rotated through a dogleg at high RPM.

Torque The BK-FX deforms less than a pin nose to pin nose connections when over torqued. Splits in full sized over-torqued couplings are nearly unheard of. Torque Graph for 5.5” 20# P110 BK-FX

Major Competitors and API Couplings can cross thread. • The pin tooth crest can ride on top of the box tooth crest past the coupling center; the cross threading leads to a crack initiated washout. • Single largest cause of failure of pin nose to pin nose semi premium connections.

Reliable Materials Unlike first generation drilling with casing connections, the BK-FX addresses the problems that have caused couplings to fail. Low hoop stress and controlled hardness couplings are utilized to reduce the chance of stress induced corrosion and embrittlement. Above 80% Yield Strength • Elements of Bad Make-up & cross threading • material failures Frac pressure • Manufacturing tolerance stacking • Hydrogen • Salt Water • Clean Steel Practices Acid • Brittleness • H2S • Chemistry • Exposure Time • • Temperature • Brittle High Stress Couplings =

Recommend

More recommend