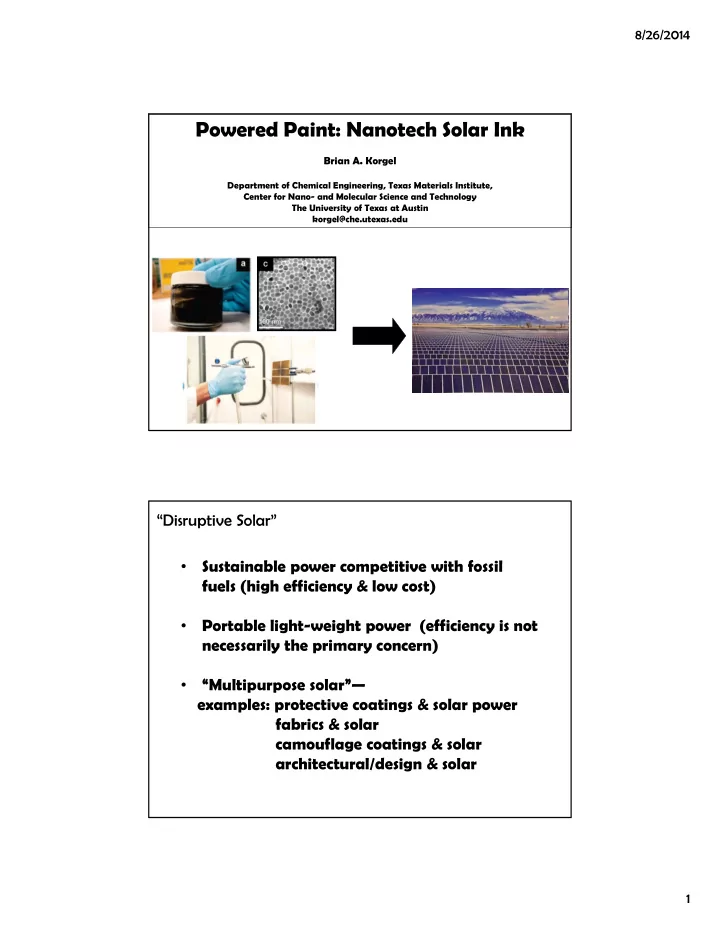

8/26/2014 Powered Paint: Nanotech Solar Ink Brian A. Korgel Department of Chemical Engineering, Texas Materials Institute, Center for Nano- and Molecular Science and Technology The University of Texas at Austin korgel@che.utexas.edu “Disruptive Solar” Sustainable power competitive with fossil • fuels (high efficiency & low cost) Portable light-weight power (efficiency is not • necessarily the primary concern) “Multipurpose solar”— • examples: protective coatings & solar power fabrics & solar camouflage coatings & solar architectural/design & solar 1

8/26/2014 To Lower the Cost of Solar Energy… Change the way solar cells are made Print like newspaper Slow, high temperature vacuum processes Photovoltaic Paints…? To Lower the Cost of Solar Energy… Change the way solar cells are made Brittle and heavy Light and flexible 2

8/26/2014 A Photovoltaic Device: metal Photons n-type semiconductor (Light) e- p-type h + semiconductor metal support This is the basic design of every solar cell Approach: Create a solvent-based ink that can be deposited under ambient conditions to obtain inorganic films for photovoltaic devices Target processability of organics (moderate processing conditions; roll-to-roll high throughput; flexible lightweight substrates) with the stability of inorganic compounds. 3

8/26/2014 Are nanocrystal PVs a viable alternative to organic PVs? 3% efficiency Sintered at high temp CdSe/CdTe…Cd-based The Technology Challenge: There is a trade-off between cost and efficiency 4

8/26/2014 Copper indium gallium diselenide: CIGS Se Single junction vapor-deposited Cu CIGS cells have reached >20% PCE; highly tolerant to grain boundaries & composition In fluctuations “Conventional” CIGS are made by vapor deposition of Cu,In,Ga layers followed by high temperature (>500 o C) Chalcopyrite phase: annealing under Se vapor Isostructural with zinc blende with ordering of Cu and In atoms in the Se sublattice Metal n-type semiconductor CIGS layer Metal Glass or plastic support 5

8/26/2014 Metal ZnO n-type CdS semiconductor Nanocrystal CuInSe 2 nanocrystals ink Metal Mo Glass or plastic support Glass Synthesis Question in 2006: Is it even possible to combine three or four elements in a flask and obtain the desired composition and phase? 6

8/26/2014 Approach to CIGS synthesis • In Sept. 2006, there was no known way to synthesize CIGS nanocrystals. • There were methods for CuInS 2 nanocrystals reported, but these gave very low yields of material. • We knew how to make copper sulfide nanocrystals, so we started there [Ghezelbash, Korgel, Langmuir , 2005] • We first synthesized CuInS 2 nanocrystals, then extended that to CuInSe 2 nanocrystals CuS nanodisks o-dichlorobenzene, 180 o C Cu(acac) 2 + S CuS nanodisks oleylamine/octenoic acid Made by Andrew Heitsch A. Ghezelbash, B. A. Korgel, “Nickel Sulfide and Copper Sulfide Nanocrystal Synthesis and Polymorphism,” Langmuir , 21 (2005) 9451-9456. 7

8/26/2014 CuInS 2 nanocrystals o-dichlorobenzene, 180 o C Cu(acac) 2 + In(acac) 3 + 2S CuInS 2 nanocrystals oleylamine CuInS 2 nanocrystals (112) EDS: Cu(L): 29% Intensity (arb. units) In(L): 25% Se(L): 46% (204) (220) (312) (200) (316) (322) (211) (400) 20 25 30 35 40 45 50 55 60 65 70 75 80 2 XRD pattern matches tetragonal (chalcopyrite) CuInS 2 8

8/26/2014 ~15 nm CuInSe 2 nanocrystals CISe oleylamine, 240 o C CuCl + InCl 3 + 2Se CuInSe 2 nanocrystals Oleylamine ligands 100 nm CIGS Nanocrystal Synthesis N 2 N 2 Tributylphosphine selenide OR Oleylamine, CuCl, Oleylamine, CuCl, InCl 3 /GaCl 3 , Se InCl 3 Heat to 180°C Heat to 260°C for 30 min Inject TBP:Se React at 240°C for 15 min Panthani, M.G.; Akhavan, V.; Goodfellow, B.; Schmidtke, J.P.; Dunn, L.; 18 Dodabalapur, A.; Barbara, P.F.; Korgel, B.A., JACS 2008 130(49), 16770 ‐ 16777. 9

8/26/2014 15 – 20 nm crystalline CuInSe 2 nanocrystals 19 A nanocrystal ink: N 2 Chemical synthesis of CIGS nanocrystals TC ~15 nm CISe Organic capping ligands oleylamine, 240 o C CuInSe 2 nanocrystals CuCl + InCl 3 + 2Se M. G. Panthani, V. Akhavan, B. Goodfellow, J. P. Schmidtke, L. Dunn, A. Dodabalapur, P. F. Barbara, B. A. Korgel, “Synthesis of CuInS 2 , CuInSe 2 and Cu(In x Ga 1-x )Se 2 (CIGS) Nanocrystal ‘Inks’ for Printable Photovoltaics,” J. Am. Chem. Soc. 130 (2008) 16770-16777. 10

8/26/2014 oleylamine, 240 o C CuCl + InCl 3 + 2Se CuInSe 2 nanocrystals Chemical synthesis of CIGS nanocrystals ~15 nm CISe oleylamine, 240 o C CuInSe 2 nanocrystals CuCl + InCl 3 + 2Se Organic capping ligands Dariya Reid (undergraduate chemical engineer) 11

8/26/2014 Nanocrystal PV Device Fabrication 2. Solution-deposit 3. Deposit heterojunction 1. Deposit metal nanocrystals partner layers (CdS/ZnO) foil onto a flexible substrate 4. Pattern metal collection grid Nanocrystal Film Formation For the solar cell, need uniform films of nanocrystals. 12

8/26/2014 • Standard Cell Efficiency 0.341% V oc 329 mV J sc 3.26 mA/cm 2 Fill Factor 0.318 ZnO CdS CuInSe 2 nanocrystals Mo Glass • Standard Cell Efficiency 0.341% V oc 329 mV J sc 3.26 mA/cm 2 Fill Factor 0.318 ZnO CdS CuInSe 2 nanocrystals Mo work function is ~4.2 eV, resulting in a Schottky barrier at Mo the Mo/CIS interface Glass 13

8/26/2014 Korgel group milestone chart for CIGS Nanocrystal PVs 3.1% Project conception (Sept., 2006) Nanocrystal Film Formation For the solar cell, need uniform films of nanocrystals. 14

8/26/2014 CIS Nanocrystal PV device 160 2 Jsc: -16.287 mA/cm 140 Current Density (mA/cm 2 ) Voc: 0.412 V 120 FF: 0.456 PCE: 3.063 % 100 80 60 Efficiency 40 of 3.1% 20 0 DARK -20 LIGHT -40 -1.5 -1 -0.5 0 0.5 1 1.5 Voltage (V) V. A. Akhavan, M. G. Panthani, B. W. Goodfellow, D. K. Reid, B. A. Korgel, “Thickness- limited performance of CuInSe2 nanocrystal photovoltaic devices,” Optics Express, 18 (2010) A411-A420. Flexible CIGS PVs 15

8/26/2014 Efficiency of 2% on plastic CIGS Nanocrystal Solar Cell Fabricated on Ultra-Light Ni-coated PET Estimated Weight 31.4”x 61.4” Panel Standard Si: 33 lbs (15 kg) CIGS on PET/Ni: 0.5 lbs (.25 kg) 16

8/26/2014 Reduce grain boundaries by synthesizing nanowires? 17

8/26/2014 Bi-seeded CuInSe 2 Nanowires by SLS NW Characterization XRD HRTEM Intensity (arb. units) Perpendicular to (112) planes Chalcopyrite CuInSe 2 10 nm 20 40 60 80 2 EDS analysis: Cu 1.0 In 0.6 Se 2.0 18

8/26/2014 Wurtzite Phase CuInSe 2 Nanowires twinning Proof of concept 2 ) 1.0 Current Density (mA/cm 0.9 Absorbance V OC = 186 mV 0.8 0.7 Band Edge J SC = 0.248 mA/cm 2 ~1 eV 0.5 0.6 FF = 0.295 0.3 = 0.014% 0.4 0.1 500 750 1000 1250 0.2 Wavelength (nm) Dark 0.0 -0.2 Light -0.4 -0.6 -0.3 -0.2 -0.1 0.0 0.1 0.2 0.3 Potential (V) Current voltage characteristics of a CuInSe 2 nanowire PV device. Inset: UV-vis-NIR absorbance spectrum of CuInSe 2 nanowires dispersed in toluene. 19

8/26/2014 CIS Nanowires PV Device Absorber Film With CdS An idealized Device device composed of structure a nanowire mat Accomplished to date: •Solar inks can be chemically synthesized •Solar cells can be fabricated with solar inks •Solar cells can be fabricated with solar inks on light-weight flexible substrates How to achieve power conversion efficiencies of 10-20%? 20

8/26/2014 Extracting the photogenerated electrons and holes efficiently is currently the biggest challenge Photons (Light) e- h + The highest efficiency devices have very thin nanocrystal layers that do not absorb all of the light ~200 nm thick layer of nanocrystals on glass disc 21

8/26/2014 Thicker nanocrystal layers absorb more light, but lead to less efficient devices 120 nm 250 nm 400 nm V. A. Akhavan, M. G. Panthani, B. W. Goodfellow, D. K. Reid, B. A. Korgel, “Thickness-limited performance of CuInSe2 nanocrystal photovoltaic devices,” Optics Express, 18 (2010) A411-A420. Thicker nanocrystal layers absorb more light, but are less efficient ~15 nm CISe 120 nm Organic capping ligands 250 nm Oleylamine 400 nm ligands V. A. Akhavan, M. G. Panthani, B. W. Goodfellow, D. K. Reid, B. A. Korgel, “Thickness-limited performance of CuInSe2 nanocrystal photovoltaic devices,” Optics Express, 18 (2010) A411-A420. 22

8/26/2014 15 nm CIS oleylamine • Nanocrystals are coated with oleylamine • Long chain hydrocarbon impedes carriertransport • Improve charge transport by replacing oleylamine 45 What to do with oleylamine? • Anneal? – Leaves surface unpassivated CIS CIS • Ligand exchange – Several attempts, but none have been successful • Larger particles – Less boundaries for carriers • Synthesize with shorter ligand – Shorter ligands are volatile, particles unstable 46 23

8/26/2014 Improving transport? Selenization of CIGS Nanocrystals for High Efficiency PV’s CIGS CIGS MoSe 2 Mo Mo CIGS Film 1 μ m 1 μ m As Deposited Selenized Boat with Se Pellets Pg 48 24

8/26/2014 CuInSe 2 nanocrystal film without annealing 200 nm CuInSe 2 nanocrystal film heated to 550 o C under nitrogen (no Se vapor)—no sintering observed 10 μ m 200 nm 25

Recommend

More recommend