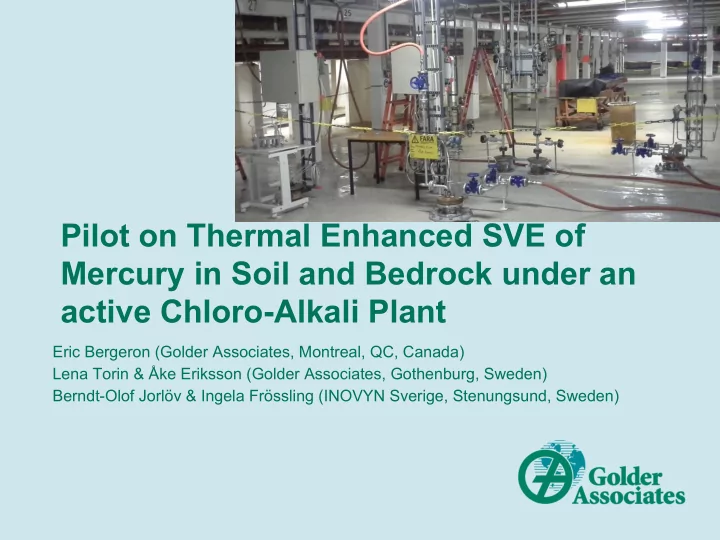

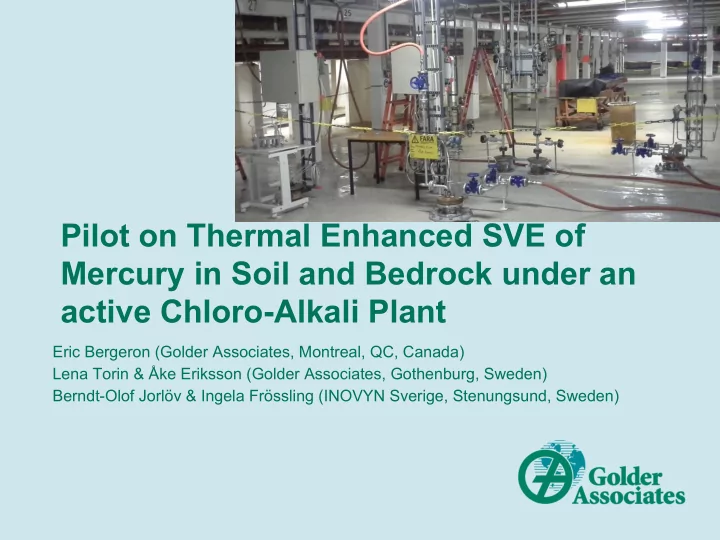

Pilot on Thermal Enhanced SVE of Mercury in Soil and Bedrock under an active Chloro-Alkali Plant Eric Bergeron (Golder Associates, Montreal, QC, Canada) Lena Torin & Åke Eriksson (Golder Associates, Gothenburg, Sweden) Berndt-Olof Jorlöv & Ingela Frössling (INOVYN Sverige, Stenungsund, Sweden)

Background Mercury based Chlor-Alkali plant ■ started in 1969 in Stenungsund Decision from the Sweden ■ government: ■ Plant must be closed down by December 2017 ■ The mercury contamin-ation needs to be remediated Investigations show almost no ■ contamination outside the plant building Up to 1,5 ton of primarily ■ elemental Hg could be present directly under the plant March 14, 2016 2

Cross-Section of the Site Approx. 1 500 kg Hg Excavation of the thin fill will probably remediate less than approx. 25 % of the Hg. Low temperature heating of soil/ bedrock coupled with SVE was determined as the Approx. 500 kg Hg are thought to be preferential, sustainable remediation present in deep fractures technique for the site. March 14, 2016 3

Pilot design Collaboration between INOVYN (process ■ engineering) and Golder Associates 3 heating wells (HW), triangular pattern ■ ■ Indirect heating of stainless steel casing by 140 O C steam from plant ■ 2.5 m down, into the bedrock 2 extraction wells (EW) ■ ■ EW-S: 1 m deep (sand and top highly fractured ”bad” bedrock) ■ EW-D: 2.6 m deep (”good” bedrock) 2 monitoring wells (MW), ~5 m deep, 4 ■ sampling levels (0.3 m, 1.75, 3, 5 m) SVE started May 7th (baseline), heating ■ started May 21th March 14, 2016 4

The pilot inside the Chloro-Alkali plant EW-S &D MW-1 MW-2 HW-1 to 3 March 14, 2016 5

Results from drilling for the pilot Water encountered 1.3 mbgs inside, but ■ ~ 5 mbgs or more outside the plant Shallow wells will be drilled next week to EW-S ■ Sand try to dewater the pilot zone Top bedrock Deep bedrock → very low permeability ■ Mass balance shows within the pilot: 20 m boring ■ Bedrock ■ Approx. 5 kg Hg in vadose zone ■ A few mg in water in the bedrock MW:s 10 m Hg in matrix (mg/ Max Mean kg) Sand 4 900 850 ”Bad” top bedrock 7.2 3.0 Bedrock 2.3 0.6 March 14, 2016 6

Results from the pilot ~20% of Hg extracted after Temperature 8 months Virtually no gas extracted from ”good” bedrock Hg in gas March 14, 2016 7

Hg-speciation results for soil and bedrock Speciation by Braunschweig University of ■ Sand: 4900 mg/kg Technology ■ Pyrolysis speciation for soil and bedrock ■ University developed speciation method for water and gas (bubbled through water) Not only elemental Hg in soil and bedrock ■ Almost 50% elemental Hg in sand that had Hg ■ droplets Elemental Hg has probably diffused into the ■ ”bad” top bedrock No elemental Hg in ”good” bedrock ■ Several other Hg-species present (HgCl 2 , HgS ■ and/or HgO) ”Bad” top bedrock: 7,2 mg/kg March 14, 2016 8

Hg-Speciation of Gas Hg part : Particle bound Hg; Hg IIb : Dissolved organic Hg (bound to BrCl-oxidable organic compounds); Hg IIa : Dissolved inorganic, reactive Hg; Hg 0 : Elemental Hg During = 3 months after heating started March 14, 2016 9

Extraction Rate Over Time March 14, 2016 10

Energy Requirements Sandy layer ( ̴ 0,5 m): 178 kW.h/m 3 ■ Bad bedrock layer ( ̴ 0,4 m): 157 kW.h/m 3 ■ Gneissic Bedrock ( ̴ 3,1 m): 60 kW.h/m 3 ■ Adapted from TerraTherm and Weston 1997 March 14, 2016 11

Results Observations: Extraction rate needs to be increased significantly ■ Temperature increase of 22°C → a seven-fold increase in vapor pressure ■ → 2.6 fold increase in extraction rate Estimated treatment time : 12 years ■ Bedrock dewatering is necessary ■ Solution: ↑ soil temperature up to 100 o C ■ Soil temperature ↑ 50 to 100 o C → 26 fold increase of the vapor pressure ■ 7.2 fold increase of the extraction rate expected ■ Estimated treatment time : 21 months ■ March 14, 2016 12

Full-Scale March 14, 2016 13

Full-Scale March 14, 2016 14

Next steps … Full scale detail design ■ Get a decision from the regulators on necessary ■ remediation The plant will close down during autumn 2017 ■ After that process equipment (cells etc.) will be taken ■ down and remediated Control room Drilling for full scale remediation will probably not ■ start before the cells are away March 14, 2016 15

Skall försöka The good collaboration with INOVYN has been key for the success of this pilot! hitta mer foton på Thanks: to INOYN! to the team! oss som varit for the good teamwork! inblandade, har ni några på er?

Recommend

More recommend