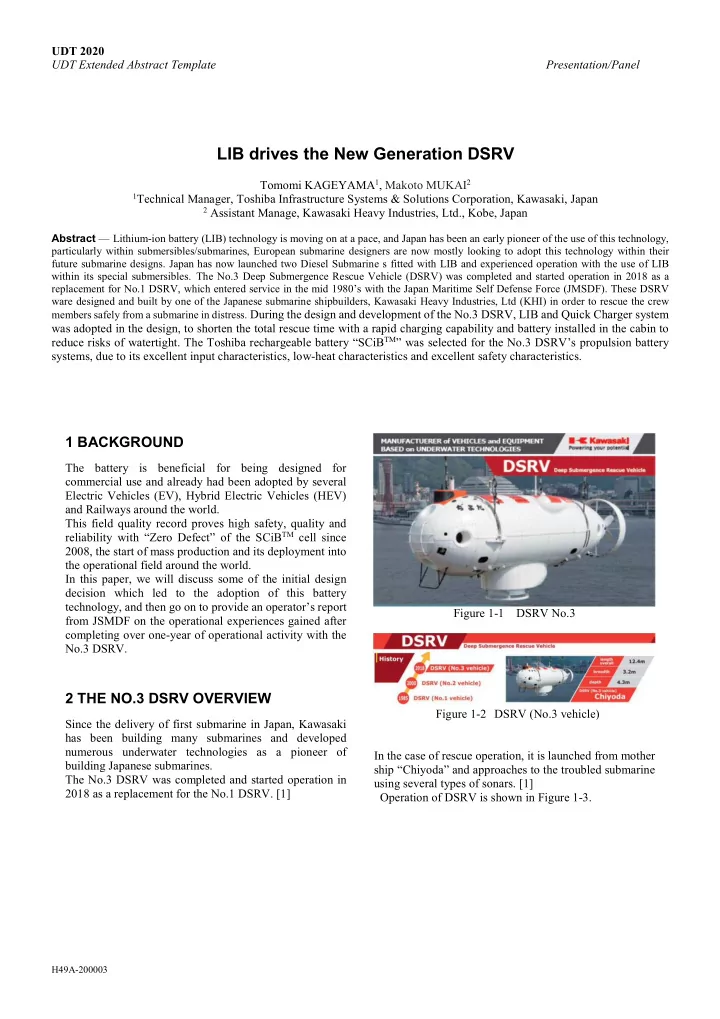

UDT 2020 UDT Extended Abstract Template Presentation/Panel LIB drives the New Generation DSRV Tomomi KAGEYAMA 1 , Makoto MUKAI 2 1 Technical Manager, Toshiba Infrastructure Systems & Solutions Corporation, Kawasaki, Japan 2 Assistant Manage, Kawasaki Heavy Industries, Ltd., Kobe, Japan Abstract — Lithium-ion battery (LIB) technology is moving on at a pace, and Japan has been an early pioneer of the use of this technology, particularly within submersibles/submarines, European submarine designers are now mostly looking to adopt this technology within their future submarine designs. Japan has now launched two Diesel Submarine s fitted with LIB and experienced operation with the use of LIB within its special submersibles. The No.3 Deep Submergence Rescue Vehicle (DSRV) was completed and started operation in 2018 as a replacement for No.1 DSRV, which entered service in the mid 1980’s with the Japan Maritime Self Defense Force (JMSDF). These DSRV ware designed and built by one of the Japanese submarine shipbuilders, Kawasaki Heavy Industries, Ltd (KHI) in order to rescue the crew members safely from a submarine in distress. During the design and development of the No.3 DSRV, LIB and Quick Charger system was adopted in the design, to shorten the total rescue time with a rapid charging capability and battery installed in the cabin to reduce risks of watertight. The Toshiba rechargeable battery “SCiB TM ” was selected for the No.3 DSRV’s propulsion battery systems, due to its excellent input characteristics, low-heat characteristics and excellent safety characteristics. 1 BACKGROUND The battery is beneficial for being designed for commercial use and already had been adopted by several Electric Vehicles (EV), Hybrid Electric Vehicles (HEV) and Railways around the world. This field quality record proves high safety, quality and reliability with “Zero Defect” of the SCiB TM cell since 2008, the start of mass production and its deployment into the operational field around the world. In this paper, we will discuss some of the initial design decision which led to the adoption of this battery technology, and then go on to provide an operator’s report Figure 1-1 DSRV No.3 from JSMDF on the operational experiences gained after completing over one-year of operational activity with the No.3 DSRV. 2 THE NO.3 DSRV OVERVIEW Figure 1-2 DSRV (No.3 vehicle) Since the delivery of first submarine in Japan, Kawasaki has been building many submarines and developed numerous underwater technologies as a pioneer of In the case of rescue operation, it is launched from mother building Japanese submarines. ship “Chiyoda” and approaches to the troubled submarine The No.3 DSRV was completed and started operation in using several types of sonars. [1] 2018 as a replacement for the No.1 DSRV. [1] Operation of DSRV is shown in Figure 1-3. H49A-200003

UDT 2020 UDT Extended Abstract Template Presentation/Panel 3 SCIB™ OVERVIEW In the commercial field, the expectation for EV is not to * Specifications shown herein are not guaranteed values and are subject to change without notice. Performance depends on usage conditions. * The package design presented here and on the web is for catalogue purpose, so the design of the actual battery will be different. * 23Ah cell uses part of technology achievement made by Japan's New Energy and Industrial Technology Development Organization (NEDO) subsidized projects. emit exhaust gas such as carbon dioxide (CO2) from consideration of environment. As a battery for EV, loading of Lithium ion battery (hereinafter referred to as “LIB”) in which small size and weight saving are possible has been started. Moreover, LIB has been adopted for the BESS (Battery Energy Storage System) for electric power compensation of commercial power transmission and Figure 1-3 DSRV Operation distribution networks which carries out the rapid charge and discharge of the high electric power. Toshiba has The No.3 DSRV was designed and built in order to rescue started production of LIB named “SCiB TM “having six the crew members safely from troubled submarine. Layout advantageous points differential from other conventional of the No.3 DSRV is shown in Figure 1-4. LIB. SCiB TM is excellent in Low-temperature operation, High input/output, Rapid charging, Wide effective SOC range, long life and safety. It is deployed such as several EV/HEV, railways, and World’s largest BESS. [2], [3] The feature of SCiB TM is shown in Figure 2-1 and the basic specification of a cell is shown in Table 2-1. Figure 1-4 No.3 DSRV Layout The sophisticated design of Kawasaki Heavy Industries shortened the No.3 DSRV construction period by minimize battery development phase, and realized TRL (Technical Readiness Level) 9. Project schedule of the No.3 DSRV is shown in Figure 1-5 Safety: Uses highly safe lithium titanium oxide (LTO) Long life: Over 20,000 cycles* Low-temperature operation: Can be used at temperatures as low as -30 °C Rapid charging: Rechargeable in 6 minutes* High input/output: Chargeable at large current and provides large current output Wide effective SOC range**: Provides a large available capacity * Measured with a particular single cell under specific conditions ** SOC: State of Charge Figure 1-5 Schedule of No.3 DSRV Figure 2-1 SCiB™ features

UDT 2020 UDT Extended Abstract Template Presentation/Panel 2.1 Concept of the SCiB TM Main Storage Battery Table 2-1 SCiB™ Cell Specification (23Ah) System (MSBS) for the No.3 DSRV Nominal capacity 23 Ah The concept of the SCiB TM Main Storage Battery System (MSBS) for the No.3 DSRV is using for SCiB TM cells and Energy density 202 Wh/L modules. It is a general-purpose commercial product which carries out packaging according to the environmental condition of the Rescue room of the No.3 Dimensions W116 × D22 × H106 mm DSRV. The configuration image of the SCiB TM MSBS is shown in Figure 2-2. Weight Approx. 550 g The features, such as high safety, high rapid charge characteristic, and a longer operating life, SCiB™ with LTO anode provides with a long life of over 20,000 charge and discharge cycles (with 3C rate equal to 300% of rated current and full depth of discharge), rapid charging, high Input/output power performance and excellent low-temperature operation, all while maintaining a high level of safety. SCiB™ has been applied to following platforms Vehicles (Passenger cars) [4] Figure 2-2. Components image of the SCiB TM MSBS - SUZUKI MOTOR CORPORATION - NISSAN MOTOR CO., LTD - Mitsubishi Motors Corporation 2.1.1 SCiB™ MSBS for No.3 DSRV - Mazda Motor Corporation SCiB™ MSBS was adopted as the MSBS of the No.3 DSRV which is operated by the Japan Maritime Self Vehicles (Commercial vehicles) [4] Defense Force. This concept was the same as the SCiB TM - Hino Motors, Ltd MSBS. It is the example of the features of SCiB TM suited - Solaris Bus & Coach S.A. to customer demand. - Val Hool - Proterra Conform to Customer Requirement; - Kawasaki Tsurumi Rinko Bus Co., Ltd - Safety; - Northern Iwate Transportation Inc. Highly safe Lithium titanium oxide (LTO) for - SCiB™ wireless charging for EV Bus Anode of SCiB TM - NEDO project in Malaysia Repeated Rapid Recharging (R3) - Low heat - Uzushio Electric Co., Ltd. generation during charge for SCiB™ Railways [5] - Long life; - West Japan railway Company (Hybrid propulsion Battery chemistry was changed from a Zinc - Silver system) Oxide Secondary Battery to SCiB TM - Tokyo Metro Co., Ltd (Emergency-Running Development cost reduction - The use of standard Battery System) commercial products (The SCiB TM Cell and - Tobu Railway Co., Ltd. (Traction energy storage Module) system (TESS)) - Actio Corporation (Battery-driven locomotive) - High reliability; - Shin-Tomoe Electric Manufacturing Co., Ltd. To enhance the reliability on the entire batteries by (Battery powered locomotive) optimized packaging Boats [5] - Tokyo University of Marine Science and 2.1.2 Export Control of Japanese Government Technology (Hybrid electric boat) Trade Control of the Japanese government for technology JR central and Toshiba jointly developed the power supply and the product which will export from Japan to the which adopted lithium ion battery for New Shinkansen overseas submersibles/submarines are controlled based on N700S. [6] the Foreign Exchange and Foreign Trade Law of Japan. The cells and modules are consumer products performing energy storage performance of the SCiB TM MSBS. For the

Recommend

More recommend