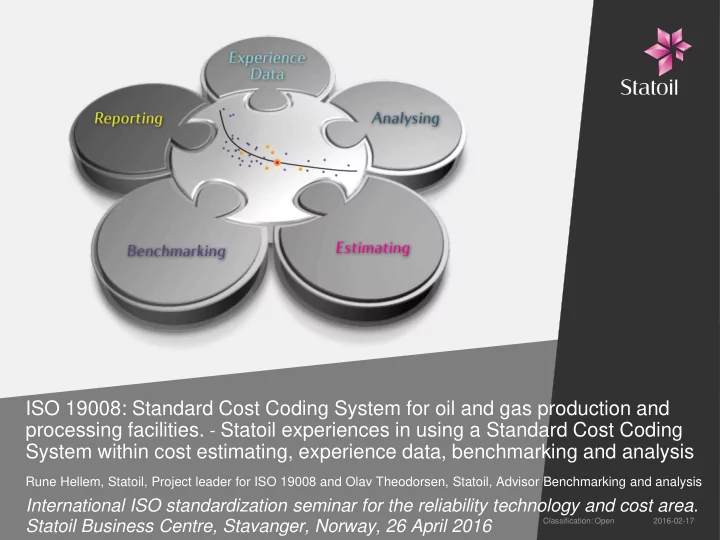

ISO 19008: Standard Cost Coding System for oil and gas production and processing facilities. - Statoil experiences in using a Standard Cost Coding System within cost estimating, experience data, benchmarking and analysis Rune Hellem, Statoil, Project leader for ISO 19008 and Olav Theodorsen, Statoil, Advisor Benchmarking and analysis International ISO standardization seminar for the reliability technology and cost area. Classification: Open 2016-02-17 Statoil Business Centre, Stavanger, Norway, 26 April 2016

Content • Background and status of developing ISO 19008 • ISO 19008 - Standard Cost Coding System (SCCS) − Users − Codes and relationships • Experience database − Collecting data − From SCCS to WBS − Use of Quantitative Experience database • Benchmarking and Analysis − Objectives with Benchmarking − Statoil’s Benchmarking Hierarchy 2 Classification: Open 2016-04-26

3 Classification: Open 2016-04-26

4 Classification: Open 2016-02-17

Users of this International Standard − Operator − Company − Contractor Both contractor and company can be using the SCCS for classifying their cost data. The appropriate codes to be used internally for cost management and controls can differ from the ones presented to the client for the CTR, but will usually be composed/aggregated according to the requirements of the client. 5 Classification: Open 2016-02-17

ISO 19008 - Standard Cost Coding System (SCCS) PBS, SAB and COR • A project independent coding system is necessary to identify cost, quantities, rates and norms across different projects • SCCS is not a project specific coding system opposed to WBS coding which is linked to the contract structure during project execution • Every cost item will be associated with a scope of work and so can be classified by each of the three aspects/facets . Each of the classifications in the facet has a numerical or alphabetical hierarchical code. • The codes are combined to create a complete composite code for the costs. The nominated order for the composite codes is: PBS, SAB, COR . 6 Classification: Open 2016-02-17

PBS - Physical Breakdown Structure Hierarchical breakdown • Defines the physical/functional components of field installations. • Enables an oil and gas production and processing facility configuration scheme to be classified. • System/facilities descriptions in PBS are only intended to provide guidelines for cost coding , as the systems/facilities normally are designed and laid out differently and uniquely for each development project according to technical and functional requirements, construction philosophy and project realisation strategies. • As a system/facility can cross individual PBS boundaries, there is no exact correlation between a system/facility and PBS . PBS code PBS code Level 3 Code name Level 2 Code name AAA Drilling area AA Topsides AAB Wellhead and riser area AB Substructures AABA Wellhead area AABB AC Offshore Wells Riser area AAC Subsea system Process and utilities AD PBS code AAD Living quarter AE Transport systems Level 1 Code name AAE Helideck AW Offshore wind park AAF Flare Offshore installations A AAG Deck appurtenances B Onshore installations AAH Deck structure PBS code Level 2 Code name BA Process, utilities and product handling PBS code BC Civil, Structures, Marine and Buildings Level 3 Code name BD Transport systems BCA Civil BCB Buildings BE Drilling facilities BF Onshore wells BCC Marine (Jetties and shore installations) BCD Structures (piperacks, modules etc.) BG Temporary facilities BH Infrastructure 7 Classification: Open 2016-02-17

SAB – Standard Activity Breakdown Hierarchical breakdown • Classifies the activity component of scope of work . • The alphabetical phase prefix introduces a code for use of SCCS throughout all phases of a project, from exploration through removal of facilities. SAB code SAB code Level 2 Code name Level 3 Code name 21 Engineering 211 Pre-execution engineering SAB code Procurement 212 Detail design engineering 22 Level 1 Code name 213 Construction / fabrication / installation 1 Management engineering 2 Engineering and procurement SAB code 214 Follow on engineering 3 Equipment and Bulk Supply Level 2 Code name 4 Construction 41 Onshore construction 5 Installation, Transport and Atshore construction 42 Logistics 43 Inshore construction Offshore construction 44 6 Other activities General activities 7 SAB – phase prefix Well Operations E Exploration 8 A Appraisal SAB code D Development Level 2 Code name P Production Land based installation 51 S Shutdown and decommissioning 52 Marine operations R Removal Logistics 53 8 Classification: Open 2016-02-17

COR – Code Of Resource Hierarchical breakdown • Classifies all project resources according to the type of contract/resource that is involved in the activity and has an associated set of rates. • Classifies the complete scale of resources involved in developing offshore and onshore facilities . COR code Level 1 Code name COR code Code name COR code COR code A General costs Level 2 Code name Level 3 Code name EA Architectural equipment E Equipment ERC Miscellaneous mechanical equipment ED Drilling equipment ERD Drivers and power transmissions B Bulk materials EE Electrical equipment ERF Heaters, boilers, furnaces and flares K Engineering personnel EG Heating, ventilation and air conditioning ERH Heat transfer equipment R Engineering overheads (HVAC) equipment ERK Compressors, blowers and expanders EJ Instrumentation equipment L Direct labour ERM Material and product handling equipment ER Mechanical equipment ERN Mechanical equipment – solids M Indirect labour ES Safety/escape and firefighting equipment ERP Pumps C Construction overheads ET Telecommunication equipment ERT Storage tanks/containment equipment – EU Subsea equipment H Company personnel atmospheric EV Mooring and marine equipment Q Company personnel overheads ERV Vessels and columns – pressurised EY Transfer and control equipment ERX Miscellaneous package units S Unit work X Marine operations and logistics Y Land based plant and equipment 9 Classification: Open 2016-02-17

Is this much? • Johan Sverdrup P1 platform 18 000 mill. NOK • Hyme subsea project 2 000 mill. NOK • Statpipe Gas Processing Plant (Kårstø) 8 000 mill. NOK 10 Classification: Open 2016-02-17

Quantitative experience data stored in Statoil’s Experience Database Classification: Open 2016-02-17

The Experience data Process “The Statoil brain” Gather Share experience experience Project phase Project phase initiation closing 12 Classification: Open 2016-02-17

Transfer of Experience data Project DG2 DG3 MCE0 CCE1 CCE2 CCEn As-built Estimation Project Control Database Experience Experience group Database 13 Classification: Open 2016-02-17

From SCCS coded Estimate to WBS • Cost estimate established by estimating department • Restructure cost estimate according to work packages for follow up in execution phase Main Contract Packages WBS structure Estimate SCCS Statoil Project X (Example) Platform Heavy PBS SAB COR Description Modifications Lift Pre-DG3 Concept AA 1 H Management Development Contractor 1 Statoil Pre-DG3 AA 211 K Studies Project Management Statoil AA 1 H Management Feed FEED Contractor AA 211 K FEED Preliminary AA Incl. mhr-rate Detail Detail engineering AA 212 K Engineering AA 31 E Equipment Procurement AA 32 B Bulk EPC ( I) Heavy Lift Fabrication AA 4141 L Prefab. Contractor Contractor Installation Installation AA 4442 L work AA 5231 XC Lifting Comm.assist. AA 447 L Commiss. Data Input level N/A Commissioni ng / testing Statoil AA 12 HFB Management 14 Classification: Open 2016-02-17

Storage of experience data by Project and PBS Example: Gjøa development project 15 Classification: Open 2016-02-17

Amount of Experience data (per April 2016) Facility Category No. Topside Modifications 205 Platform 138 Subsea 122 Onshore Facilities 111 Transport Pipeline 90 Wells 72 Offshore Storage and Offtake System 12 Offshore Cable-Umbilical 12 Offshore Bridge 8 Offshore Fibre Optic Cable 8 Onshore Cable-Umbilical 7 Cessation Platform 4 Cessation Subsea 2 16 Classification: Open 2016-02-17

Quantitative data available in Database • Project cost and quantities – at a detailed level • Cost plan (investment profile) • Currency shares from contracts • Design data • Overall quantities (weights, man-hours etc.) • Main Schedules & milestones • Progress curves 17 Classification: Internal 2015-06-04

Benchmarking and Analysis Classification: Open 2016-02-17

Benchmarking Why benchmarking: LEVEL 1 • Capacity vs. reserves • Decision support Business • CAPEX vs. reserves case cost • Estimate calibration - Facilities & wells $/boe efficiency - Facilities only • QC of estimates • Challenge technical LEVEL 2 • Total platform - Jacket/FPSO/Semi/etc. • Communication Concept - Topsides/substructure Metrics by cost • Pipelines facility category efficiency • Subsea • Onshore LEVEL 3 • Norms and rates • Unit cost Key Component cost - Material cost - Engineering on discipline level drivers - Construction • Etc. 19 Classification: Open 2016-02-17

Recommend

More recommend