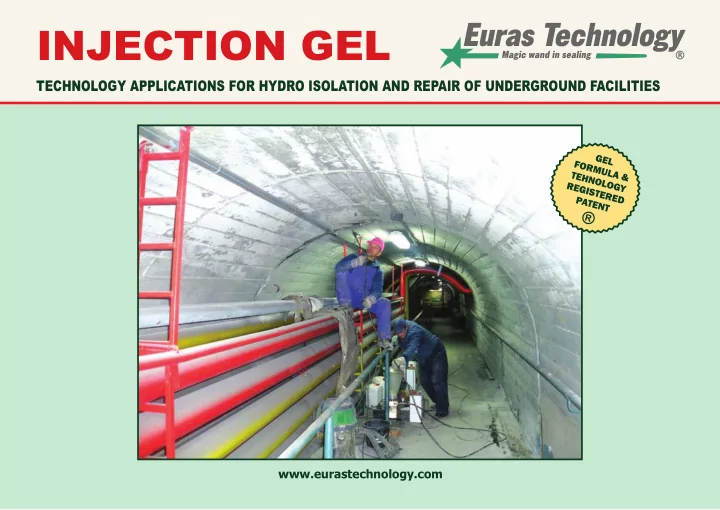

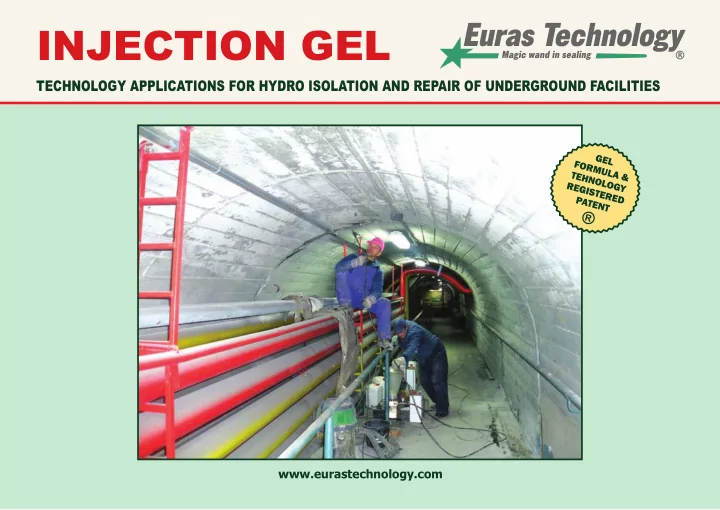

TECHNOLOGY APPLICATIONS FOR HYDRO ISOLATION AND REPAIR OF UNDERGROUND FACILITIES INJECTION GEL www.eurastechnology.com

WHAT IS INJECTION GEL? An injectable gel is a flexible mass of mineral origin, for both dry and wet surfaces solvent-free, durable soft-flexible. It is resistant to weather influences and UV radiation. It is resistant to frost and temperatures up to +100 C. It has a binding capacity of water, and squeezes out the remaining water from its environment. As a gel, the substance is water resis- tant and has high resistance to diffu- sion, to salt water and cold tempera- tures. It is not corrosive and is not affected by operations in bituminous surfaces.

An injectable gel is a particularly convenient and irreplaceable in the prevention of water penetration into the interior of underground (basement) rooms, or for recovery of inaccessible parts of underground or partially underground facilities, tunnels, hydroelectric power plants, swimming pools, fountains, and the like. The material is suitable for sealing surfaces and joints in materials such as concrete, brick, glass, ceramic, aluminum, iron and all kinds of steel, copper and various synthetic materials. WHERE TO APPLY INJECTION GEL?

Repair, in most cases, is achieved by drilling injection holes in the damaged area of a preventing remaining potential impacts of groundwater under pressure to occur. HOW TO APPLY penetration. and therefore the successful remedial and preventive actions to possible further water water, what finally results in a successful elimination of water from the damaged zone squeezed out. The mass remains permanently in the gel state, blocks the passage of The amount of gel that is injected, in principle, corresponds to the volume of water that water is permanently removed from an affected zone, and gel takes its place thus structure and placing injection packs (operating and control) into them. The number and Injection is performed until on control packs, instead of water, gel appears. This ensures gel is injected in the direction from which water under pressure enters into the interior. Through operating packs working under high pressure (50-200 bars) the right amount of which the element is made of. water inflow, dimensions of the elements that are drilled and quality of the material from arrangement is determined separately for each case and depends on the quantity of INJECTION GEL?

TECHNICAL DATA « DESCRIPTION: Single component gel « BASIS: Mineral, alkaline « COLOR : Mint turquoise « SPEC. GRAVITY: 1,1 « TOXICITY : None « CORROSIVENESS: None

Euras gel type -20 concerning the conditions of application of gels in As a result of testing and development of new technology for gel injection , there is a remarkable result in anti-corrosive properties of the material, so that it is increased above pH 10 (passivation of reinforcement steel). Thus a requirement by Deutsche Bahn AG is satisfied the repair of reinforced concrete structures of its placing. (tunnel). The system is in the process of certification at the Institute in Germany, what will open a possibility for applications in a seamless system of expansion joints rehabilitation in tunnels . According to our knowledge it is currently the only system that meets the latest technical requirements. Euras gel type 10+ a waterproofing function from the first moment A new type of gel injection, offering all the usual We have developed a new type mortar injection features, manages to maintain resistance to 0 freezing to -20 C. Applications include the areas exposed to severe frosts, near the surface (the tunnel's entrance, flat roofs, ...etc). Euras injection mortar (with or without use of cement) that is used for except for contact constructive functions, also contact and injecting underground structures, which, unlike other materials of the group dur- ing injection, remains homogeneous , without changing water-cement ratio and without 3 decomposition, specific gravity of 2.10 t/m . This procedure enables mortar to achieve, OUR RECOGNIZED PRODUCTS

GROUNDWATER CONCRETE STRUCTURES inflow into segregated or otherwise dam- « Injection gel for sealing off large water concrete structures dry and wet cracks as well as pre-stressed « Epoxy resin (EP) for fast static closure of water inflow cracks, segregated concrete and similar « PUR foam resin for instant sealing off of dilatation injection hoses for sealing off operational « Polyurethane resin (PUR) infused into closure of wet and water ridden cracks « Polyurethane resin (PUR) for sealing and Injection: moist walls made of mixed material STRUCTURE REPAIR ground and as silicon material support in insulation of area of contact with moist « Injection gel for filling in cavities in walls, of capillary moisture in walls « Silicon material for additional insulation stone walls tion of capillary moisture in brick and « PUR resin for additional horizontal insula- masonry structures « Cement grout for sealing cavities in dry and wet cracks « Micro-cements for sealing and closure of Injection: BRICK AND STONE STRUCTURES aged concrete

GROUND WATER associated corrosion of armature tal and vertical dilatations with high « Flexi-plastic material for filling horizon- Infusion: through damaged dilatation areas tioning, preventing any water inflow enables undisturbed dilatation func- an permanently flexi-plastic compound tion permanently replaces water and as « Injection gel infused in area of dilata- Injection: DILATATION aged areas of concrete structures and STRUCTURE REPAIR « Polymer Concrete for repairing dam- water tank protection « Flexible polymer multi-layer coating for from underground water for the protection of underground walls « Flexible bituminous multilayer coatings installation of concrete constructions protection of surfaces which follows the « Geo textile membrane for groundwater Injection: DAMAGED AREAS chemical resistance

DESIGN AND CONSULTING RELATED TO GROUNDWATER PROBLEMS DURING THE CONSTRUCTION OF NEW BUILDING STRUCTURES « Designing of execution details regarding ground water problems « Supply and installation of the designed systems to protect new structures against ground water « Expert supervision in the execution of o the designed details

Recommend

More recommend