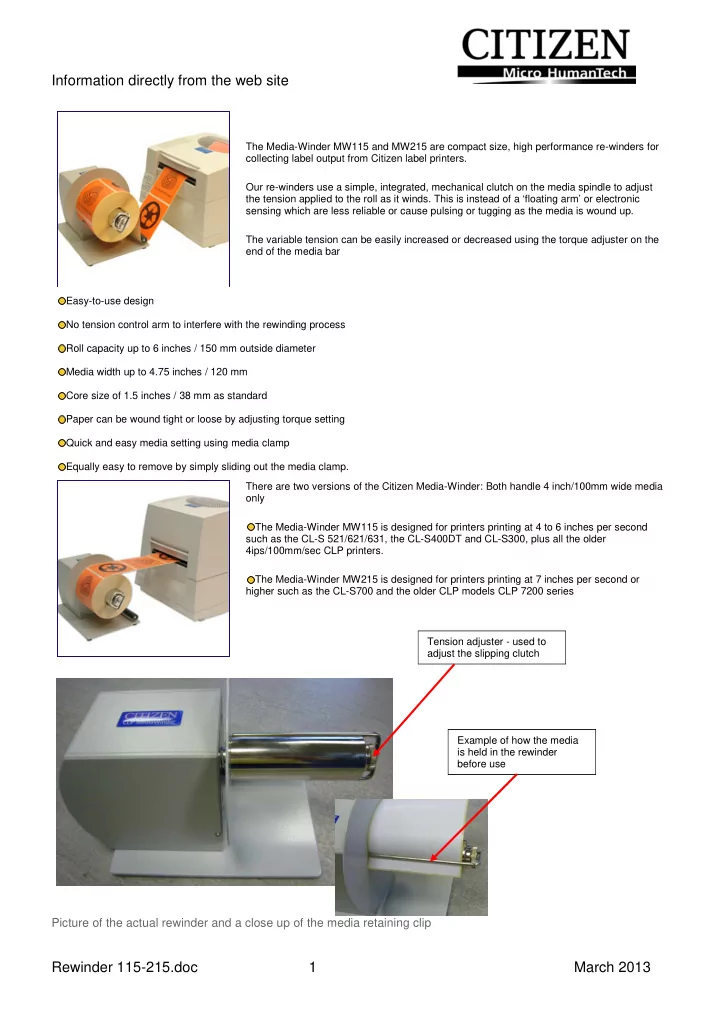

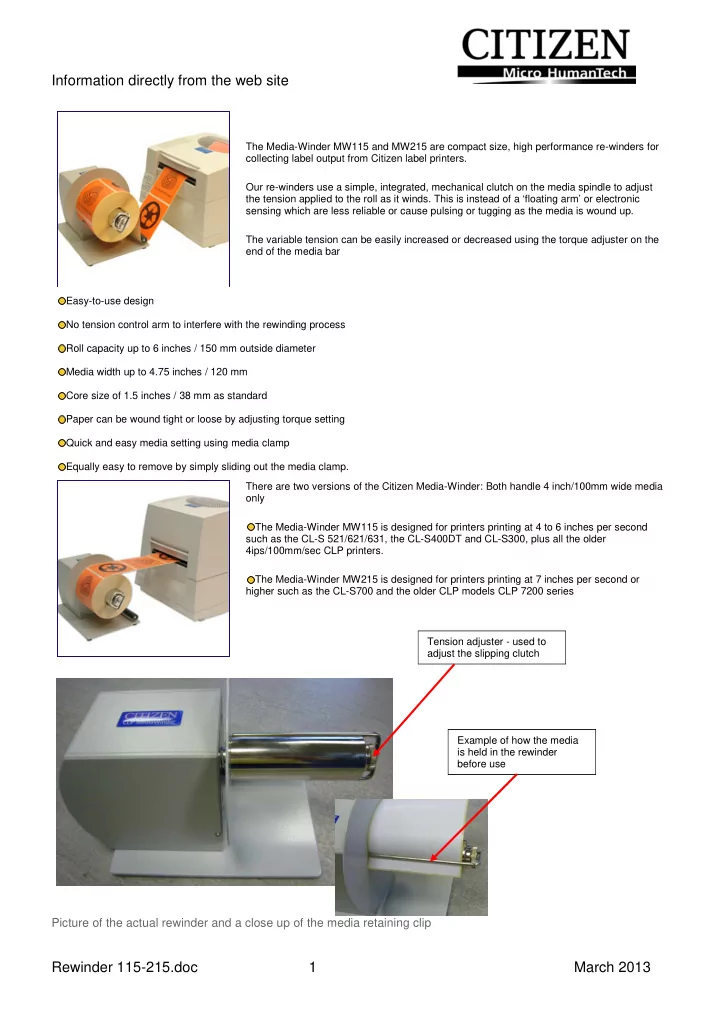

Information directly from the web site The Media-Winder MW115 and MW215 are compact size, high performance re-winders for collecting label output from Citizen label printers. Our re-winders use a simple, integrated, mechanical clutch on the media spindle to adjust the tension applied to the roll as it winds. This is instead of a ‘floating arm’ or electronic sensing which are less reliable or cause pulsing or tugging as the media is wound up. The variable tension can be easily increased or decreased using the torque adjuster on the end of the media bar Easy-to-use design No tension control arm to interfere with the rewinding process Roll capacity up to 6 inches / 150 mm outside diameter Media width up to 4.75 inches / 120 mm Core size of 1.5 inches / 38 mm as standard Paper can be wound tight or loose by adjusting torque setting Quick and easy media setting using media clamp Equally easy to remove by simply sliding out the media clamp. There are two versions of the Citizen Media-Winder: Both handle 4 inch/100mm wide media only The Media-Winder MW115 is designed for printers printing at 4 to 6 inches per second such as the CL-S 521/621/631, the CL-S400DT and CL-S300, plus all the older 4ips/100mm/sec CLP printers. The Media-Winder MW215 is designed for printers printing at 7 inches per second or higher such as the CL-S700 and the older CLP models CLP 7200 series Tension adjuster - used to adjust the slipping clutch Example of how the media is held in the rewinder before use Picture of the actual rewinder and a close up of the media retaining clip Rewinder 115-215.doc 1 March 2013

Citizen Rewinder operation The rewinder shown is the 2000422 but both units we supply look exactly the same. Part number of the other unit 2000423 The arrow points to a media support or guide bar and roller which can be used to help media winding but in our document it is not used. The unit is supplied with a European plug but for units sold in the UK a quick and easy option is to buy an adapter locally. The back of the unit is also shown above right. Loading paper. Ideally, position the re-winder close to the printer which eases the amount of media wasted during set up. The rewinder can be positioned elsewhere but during the winding process it should be in-line with the printer as shown Remove the media retaining bar Do not lose this item as it is used to hold the media on the rewinder during operation. Using the rewinder-V1.doc - 1 - June 2013

The large picture below shows the media loaded and held in position by the retaining bar. It is possible to clip either the backing paper as shown (we have removed several labels to do this) OR just clip the media as shown in the inset. Turn ON the rewinder and the media will tension itself. Because the unit has a slipping clutch once the tension is taken up the winder runs but just holds the media tight. It is possible to reset this tension by tightening OR loosening the knurled wheel at the end of the winding shaft (arrowed). Using the rewinder-V1.doc - 2 - June 2013

Printing and winding As a demo we have printed the printer’s configuration report and self-test. Below you can see the media has been tensioned and the printed labels are being wound on to the roll holder. The rewinder keeps the media tight and as printing takes place the rewinder will wind up the labels at the same pace as the printer prints. Once the required number of labels has been printed, turn off the rewinder and tear off the media from the printer. Take hold of the wound media and slide the retaining clip out as shown. Then take the roll of media off the rewinder. Using a Peeler . If a Peeler is being used we would suggest the rewinder be placed below the printer or even behind it, the backing paper passing under the printer. This way, as the backing paper is coming off the printer with each label removed the backing paper is always held tight and is also out of the way Using the rewinder-V1.doc - 3 - June 2013

Recommend

More recommend