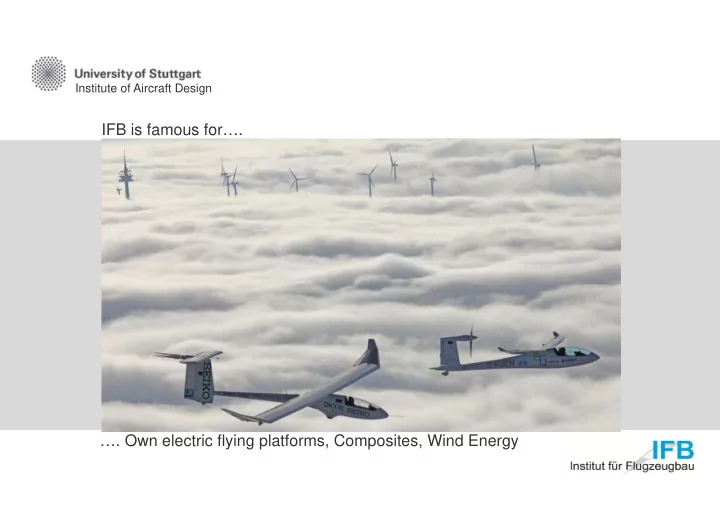

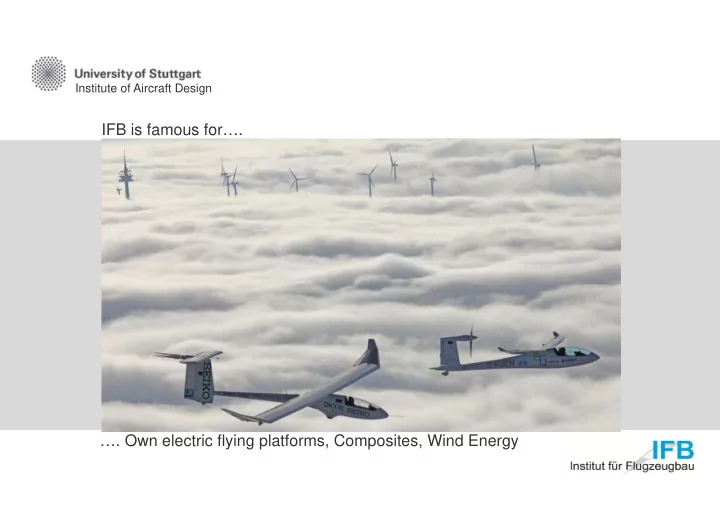

Institute of Aircraft Design IFB is famous for…. …. Own electric flying platforms, Composites, Wind Energy

Institute of Aircraft Design Research Areas Aircraft Design Prof. Strohmayer Manufacturing Lightweight Design Technologies Prof. Middendorf Prof. Middendorf Wind Energy Prof. Cheng staff: 3 professors - 60 academics - 11 accommodation: 2 buildings - 1000m 2 office - 250m 2 seminar rooms - 300m 2 engineers - 5 administrators - ~80 laboratories - 1300m 2 workspace - 300m 2 students - 4 trainees sales: 25% basic funding - 75% third- storage party-funds University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 2

Institute of Aircraft Design Composites 30 scientific engineers are dealing with composites Resin Infusion and Injection Testing and Material Structure Simulation Optimization Characterization COMPOSITES COMPOSITES SIMULATION MANUFACTURING Preform Draping and Handling Automated Multiscale Material with Integrated QA-System Preforming and Process Simulation Modelling Fibre Placement University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 3

Institute of Aircraft Design More than Lectures Industry Cooperation Public Funded Projects University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 4

Institute of Aircraft Design Experience in Preform Technologies Since 2005 University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 5

Braided Manipulator (ZASCHE handling) Development of a Carbon Manipulator using Braiding Technology • Low-weight carbon manipulator (70% less weight compared to steel) • Radial braiding technology for efficient manufacturing • High bending and torsional stiffness for easy manipulation University of Stuttgart 26.11.2017 6

4. Braiding technology Example: R.A.C.E. Plate Holder University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 7

Tailored Fibre Placement • Load path optimized lay-up • Low cut-off (Near-Net-Shape) • High volume production possible • Multimaterial process • High Design freedom IFB University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 8

Tailored Fibre Placement - Introduction University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 9

ZIM: Innovative design and process chain for multifunctional parts made of continuous glass or carbon reinforced thermoplastics • Machining of thermoplastic hybrid yarns by using the TFP technology • Development of a pressing/grouting process for the TFP preforms • Integration of functions of the consolidated preforms by • Materials: Carbon fiber/PA6 und glass fiber/PA66 • Analysis of characteristic material values • Part design using the example of a torque support In Cooperation with: 26.11.2017 10

Production Steps of a TFP Process TFP Preform Die-cutting Consolidation Machining Final Part Overmolding 26.11.2017 11

Designchain of a TFP Process Demonstrator part FEM analysis Design of Preform topography Torque support AOPS TFP pattern analysis EDOPath Topography extraction MoldFlow CFD Analysis CAD tool design for EDOPath overmolding paramter grouting/overmolding 26.11.2017 12

Institute of Aircraft Design Resin Infusion Process: Vacuum Assited Infusion VARI - Vacuum Assisted Resin Infusion VAP - Vacuum Assisted Process To get a higher consolidation the Standard set-up in Set-up in oven or in a process can be single sided mould closed mould with done within an with line injection cascade injection autoclave. University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 13

Institute of Aircraft Design Resin Infusion Process: Resin Transfer Moulding (RTM) RTM with press control and injection machine RTM with transparent mould Monitoring und control of temperature and pressure in the mould, at the inlet point,… Teaching application: Visualizing the effects of vacuum, injection Field of application: pressure, temperature, flow front speed, heating Basic research and development, prototyping, and cooling rates on the mould filling behaviour process optimization and small series and laminate quality production University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 14

Institute of Aircraft Design Out of Autoclave Processes, Wet Pressing Wet pressing with press control Wet pressing with local 3D application reinforcement and one shot sandwich structures Monitoring und control of temperature and pressure in the mould, Field of application: Process figures: Basic research and development, prototyping, 30 sec.- 1 min. curing, part to part < 2min., process optimization and small series 58%-60% FV, < 1% void content production University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 15

Institute of Aircraft Design New APP Concept wit OoA Curing material @IFB • Novel out of autoclave manufacturing process • 3D placement technology for plies and tapes • Wrinkle free placement of double curved surfaces www.lowflip.eu • Energy efficient and fast heating tools University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 16

Institute of Aircraft Design New APP Concept wit OoA Curing @IFB University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 17

3D Stitching: Equipment and Competences • Robot-supported stitching, allowing the stitching of complex 3D-Geometries • Experience with multiple single-sided stitching techniques. • Further understanding of through-the- thickness reinforcement through stitching. Improvement of interlaminar strength Damage tolerance Crack growth arrestment University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 18

Research Focus: Selective Stitching Identification of the most efficient stitching configurations for CFRP stiffened panels in terms of damage tolerance • Establishing a correlation between coupon-level and substructure-level results. • Development of fail-safe structures that control damage growth through stitching. • Isolation of the contribution of stitching to the inter-laminar strength of a laminate. • Determination of the most suitable stitching techniques and positions that provide better stiffener-skin joints. • Reduction of time and material costs, while still obtaining damage tolerant structures. • Determination of the most appropriate method for on-line damage growth monitoring. University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 19

Simulation at IFB Overview Material Characterization Numerical Simulation Manufacturing Process + Validation • Textile Characterization • Different Simulation • Textile Processing (Braiding, Methods (FEM, CFD, Draping, Tailored Fiber • Mechanical Testing analytical) Process, Stitching) • Structural Testing • Process Simulation • Resin Infusion (VARI, VAP, • Non-Destructive Testing RTM) • Structural Simulation • Prepreg University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 20

Simulation at IFB Virtual Process Chain OPTIMIZATION STRUCTURAL SIMULATION Simulation 15 Phd, 2 Teams Manufacturing and Process Simulation at the IFB Braiding simulation, Draping Simulation, Infusion Simulation, CAM Structural Simulation PROCESS MULTISCALE Impact, Crash, Fatigue, Design Optimization, SIMULATION MODELLING Joints Simulation, Sandwich Structures, Effects of Defects Software ESI, Abaqus, LS Dyna, Hyperworks, Matlab, etc. Hardware HPC Cluster, Intel XEON, Quad-, Octa-, 12-Core 4,7TFlops 26.11.2017 21

OPTIMIZATION Multi-Scale-Modeling Overview STRUCTURAL SIMULATION SIMULATION PROCESS Approach • Implementation of the real composite • Unit-Cell Models: architecture into the structural simulation • Stiffness and strength calculation MULTI-SCALE MODELLING • Obtain macroscopic material model for large • Volume fraction influence structural simulation • Preform simulation to determine real fiber orientation University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 22

OPTIMIZATION Process Simulation Overview Application-oriented Modelling Virtual Process Optimization Data Transfer STRUCTURAL SIMULATION SIMULATION PROCESS Background: Application: • Modelling manufacturing process of FRP • Predict real fiber architecture for structural Structures simulation considering influences of manufacturing MULTI-SCALE • Consider physical effects process MODELLING • Different levels of detail depending on application • Neutral data format for data transfer • CAM-Interface • Virtual process optimization University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 23

OPTIMIZATION Process Simulation Braiding Simulation Fiber Angle Change Gaps STRUCTURAL SIMULATION SIMULATION PROCESS Detaching Approach: Advantage: • Mesoscopic, explicit FEM-Simulation with beams or • Modelling of real physical phenomenon MULTI-SCALE shell elements for modelling of fibers • Fiber angle deviation, gaps, detaching of layers, MODELLING compaction effects • Possibility of dynamic and friction effects • Process related part design representation • Process planning and optimization possible • In-house pre-processor University of Stuttgart - Dr.-Ing. Stefan Carosella 26.11.2017 24

Recommend

More recommend