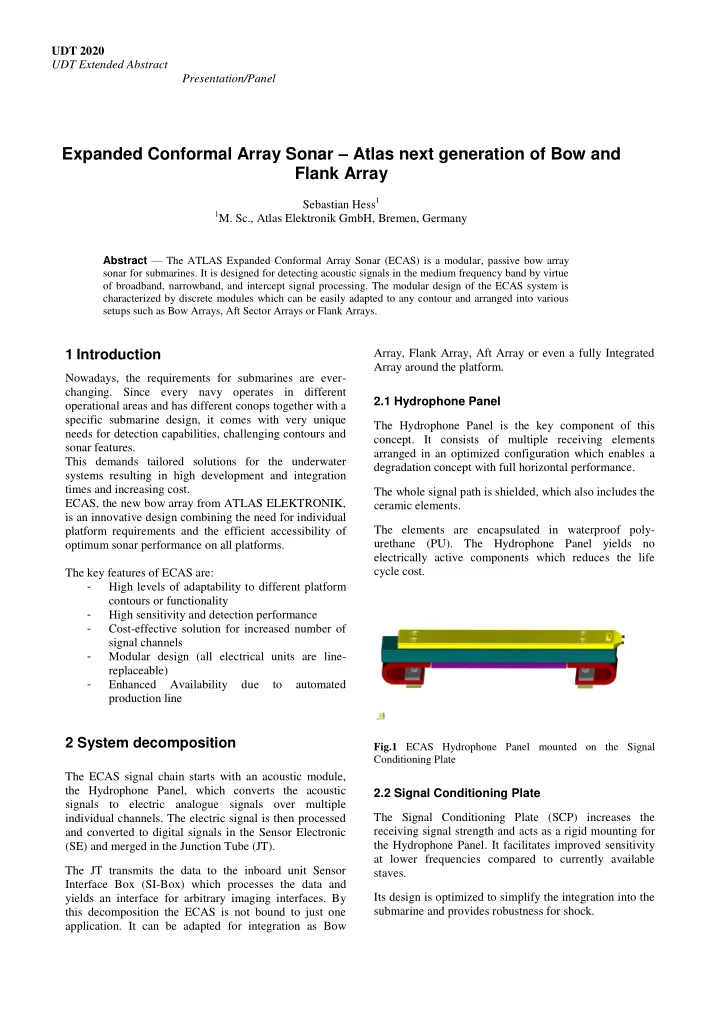

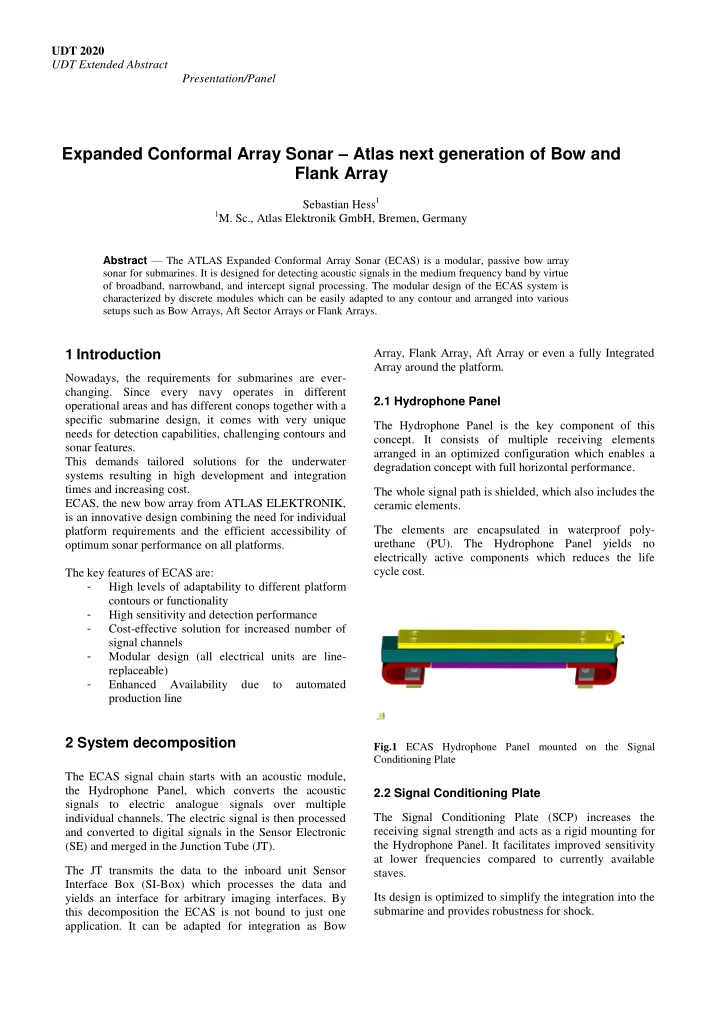

UDT 2020 UDT Extended Abstract Presentation/Panel Expanded Conformal Array Sonar – Atlas next generation of Bow and Flank Array Sebastian Hess 1 1 M. Sc., Atlas Elektronik GmbH, Bremen, Germany Abstract — The ATLAS Expanded Conformal Array Sonar (ECAS) is a modular, passive bow array sonar for submarines. It is designed for detecting acoustic signals in the medium frequency band by virtue of broadband, narrowband, and intercept signal processing. The modular design of the ECAS system is characterized by discrete modules which can be easily adapted to any contour and arranged into various setups such as Bow Arrays, Aft Sector Arrays or Flank Arrays. 1 Introduction Array, Flank Array, Aft Array or even a fully Integrated Array around the platform. Nowadays, the requirements for submarines are ever- changing. Since every navy operates in different 2.1 Hydrophone Panel operational areas and has different conops together with a specific submarine design, it comes with very unique The Hydrophone Panel is the key component of this needs for detection capabilities, challenging contours and concept. It consists of multiple receiving elements sonar features. arranged in an optimized configuration which enables a This demands tailored solutions for the underwater degradation concept with full horizontal performance. systems resulting in high development and integration times and increasing cost. The whole signal path is shielded, which also includes the ECAS, the new bow array from ATLAS ELEKTRONIK, ceramic elements. is an innovative design combining the need for individual The elements are encapsulated in waterproof poly- platform requirements and the efficient accessibility of urethane (PU). The Hydrophone Panel yields no optimum sonar performance on all platforms. electrically active components which reduces the life cycle cost. The key features of ECAS are: High levels of adaptability to different platform - contours or functionality High sensitivity and detection performance - Cost-effective solution for increased number of - signal channels Modular design (all electrical units are line- - replaceable) Enhanced Availability due to automated - production line 2 System decomposition Fig.1 ECAS Hydrophone Panel mounted on the Signal Conditioning Plate The ECAS signal chain starts with an acoustic module, the Hydrophone Panel, which converts the acoustic 2.2 Signal Conditioning Plate signals to electric analogue signals over multiple The Signal Conditioning Plate (SCP) increases the individual channels. The electric signal is then processed receiving signal strength and acts as a rigid mounting for and converted to digital signals in the Sensor Electronic the Hydrophone Panel. It facilitates improved sensitivity (SE) and merged in the Junction Tube (JT). at lower frequencies compared to currently available The JT transmits the data to the inboard unit Sensor staves. Interface Box (SI-Box) which processes the data and Its design is optimized to simplify the integration into the yields an interface for arbitrary imaging interfaces. By submarine and provides robustness for shock. this decomposition the ECAS is not bound to just one application. It can be adapted for integration as Bow

UDT 2020 UDT Extended Abstract Template Presentation/Panel 2.3 Sensor Electronic The Sensor Electronic is situated in pressure resistant housing located in the bow section. It can be placed independently from the Hydrophone Panel. The housing is made of corrosion resistant stainless steel and is tested to be shock proof. The simple design with integrated Fig.4 ECAS SI-Box health monitoring makes it easy to replace any electrical part. The Sensor Electronic is designed to process up to 64 3 Design approach analogue channels. Its low power consumption design ECAS is able to steer the vertical beams sophistically and allows a single channel conversion – to? a large number can reduce the environmental noise which yields of channels. However, the SE brings additional system potential target separation and added detection range. fail safety by being able to process different groups of The vertical beam steering serves also to compensate one Hydrophone Panel separately. Electrical self noise is installation tilt angles and offers the additional advantage reduced beyond Sea State 0 by isolating the SE. of reducing noise influence from the sea surface.Therefore data from every single hydrophone has to be transfered inboard individually as an enabling technology for vertical beam steering. The ECAS Hydrophone Panel yields enough single elements in one stave to fulfil modern needs of vertical beam steering without exceeding form factors or energy consumption. The design of underwater electronics is always a challenge and the latest technology iteration has become even more elaborate. To achieve optimum sonar performance, the number of hydrophones featured by Fig.2 ECAS Sensor Electronic housing these sonar antennas is crucial. It demands sonar antenna 2.4 Junction Tube manufacturing at the highest standards by applying innovative automated production and quality control The Junction Tube collects the data from up to six Sensor technologies. Electronics and streams it to the inboard Sensor Interface An automated manufacturing approach makes it possible Box via optical 1000 Base-TX Ethernet. to adapt to new applications easily while keeping the integration time low. For system fail safety it features redundant power supply By separating the SE from the Hydrophone Panel, the interface, synchronisation input and data transfer output. factor life cycle cost is taken into account. By making every unit line replaceable, a damaged Hydrophone Panel can be exchanged independently and spare parts come with reduced costs. 4 Conclusions At the commencement of the ECAS design, the aim was to develop a system that is easy to adapt to any platform contour. However, this has unravelled into a more Fig.3 ECAS Junction Tube powerful system approach that yields many applications. 2.5 Sensor Interface Box With a set of standardized components with defined interfaces and a sensing element that is slim enough to fit The SI-Box is the inboard main interface for any signal in many positions but also performant enough to adapt to processing and imaging components. It replaces the many applications it was possible to form more than just ATLAS Terminal Adapter (TAD) by merging the data a Bow Array. stream capabilities and data processing. ECAS in its early stage, is proven to be compatible to applications such as Flank Array and Aft Sector Array. Its slim design and different interfaces facilitates easy Its COTS-character puts development and integration inboard integration to arbitrary systems. time for a new platform to a minimum.

UDT 2020 UDT Extended Abstract Template Presentation/Panel With this proven concept, ECAS will be the one-fits-all solution for future submarines that combines the key requirements of today: maximum performance combined with short time availability and minimized life cycle costs.

Recommend

More recommend