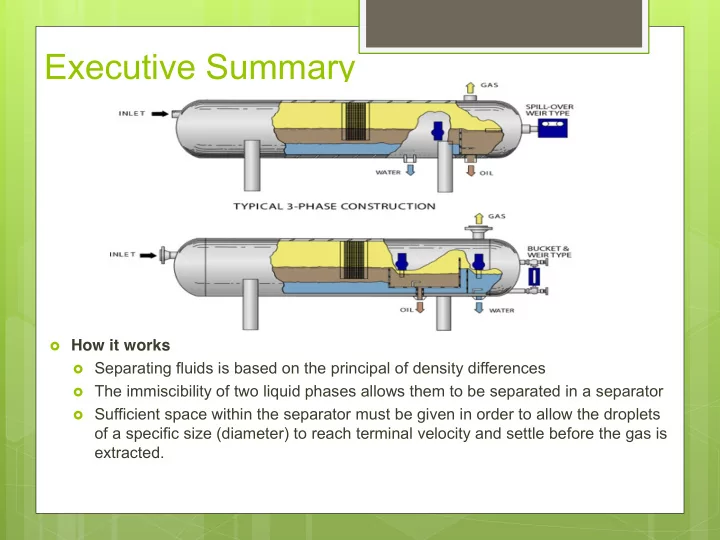

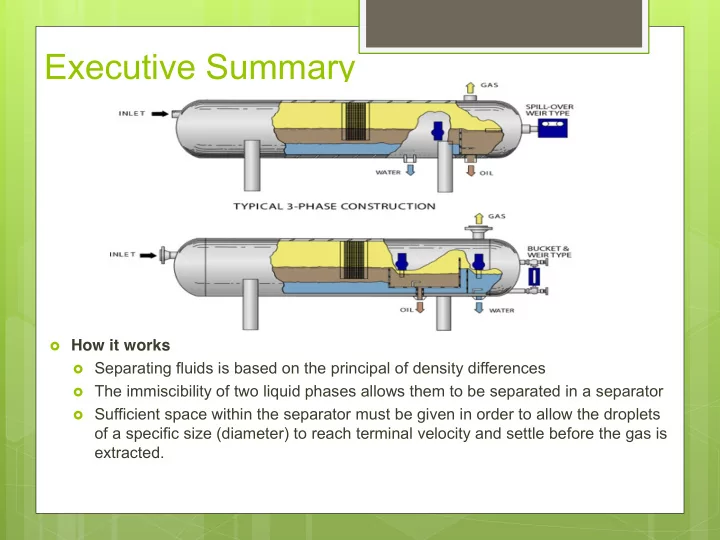

Executive Summary How it works Separating fluids is based on the principal of density differences The immiscibility of two liquid phases allows them to be separated in a separator Sufficient space within the separator must be given in order to allow the droplets of a specific size (diameter) to reach terminal velocity and settle before the gas is extracted.

Advantages (vertical) Advantages (horizontal) Does not need significant They are less expensive liquid retention volume than vertical separators, though they are used for liquids with less sludge and sediments. Vertical separators are Horizontal separators are capable of handling large ideally suited for streams slugs of liquid and are having high gas-oil ratios, therefore most often used constant flow, and small on low to intermediate liquid surge characteristics gas-oil ratio well streams They are well suited for Better at handling larger handling liquids that feed flow rate contain sands and other sediments The separator occupies a Due to its large interfacial small amount of plot areas, it has better phase space separation capability

Sizing Cost Estimation – Capital cost) Cost (2011) Lower Bound ($) Upper Bound($) $ 41374.74 $24824.84 $57924.63 References Abdel-Aal, H. A. (2003). Petroleum and Gas Field Processing. Marcel Dekker Inc. James H. Taylor, A. F. (n.d.). Modeling and Control of Three-Phase Gravity Separators in Oil Production Facilities . Retrieved November 10, 2012, from http://www.ece.unb.ca/jtaylor/Publications/acc07_pilot.pdf

Carbon Capture Sequestration Ultrafiltration for CCS Hollow Fibers

Overview of annual operating cost Membrane Replacement Membrane lifetime Rate of replacement Energy Power and efficiency of pumps Total flow rate Reference ◦ Wilcox.Jennifer “Carbon Capture”, New York: Springer, 2012 ◦ Sandeep . S, “ Transient permeate flux analysis, cost estimation, and design optimization in cross-flow membrane filtration ” Department of Danny Luu Environmental Science and Engineering, Rice University,1997 Jessica Tang

GLYCOL DEHYDRATION by Dan Gariepy and Kristen Kolynchuk Absorption Column: Purpose: removes water vapour from wet natural gas ● water content decreases process efficiency ● and can damage process equipment companies have specifications on the water ● content of gas they will purchase (approx. 0.000112 kg H2O /m 3 gas) ○ Triethylene Glycol (TEG) Molecular Structure: Separation Mechanism: an absorption column can remove water ● vapour from natural gas, using TEG as the Bubble-Cap Tray: absorbent TEG has high affinity for water, facilitated ● by it's hydroxyl & ether groups water vapour in the gas will be absorbed by ● TEG as the streams are contacted bubble-cap trays contact the wet natural gas ● with TEG

COST ESTIMATION Mass Balance: Column Properties amount of H 2 O in inlet gas was ● # of Trays 8 determined using Raoult's law: Spacing 3.625 ft First Year Costs [2012 dollars] (Vapour pressures from Antoine's Equation) Diameter 5.0 ft Unit Cost $136,436 mass of H2O removed determined ● Height 29.0 ft using the company specifications Installation $272,872 Volume 569.4 ft 3 circulation determined amount of ● Maintenance $10,593/year TEG required to remove H2O Temperature 100 o F Labour $200,000/year Pressure 1200 psig TEG Flow $53,896/year Capacity 169.93 m 3 /h Total Cost: $673,797 Circulation 25 L TEG /kg H2O TEG Price $0.09/kg TEG Duration 3840 h/year References: 1. Manning. Francis. S, Thompson, Richard. E. “Oilfield Processing: Natural Gas” PennWell Publishing Company, South Sheridan, Tulsa, Oklahoma. 1991. 2. Guo. Boyun, Lyons. William. C, Ghalambo. Ali, “Petroleum Production Engineering: A Computer Assisted Approach” Linacre House, Jordan Hill, Oxford. 2007.

Biodiesel ¡Produc-on ¡from ¡Vegetable ¡Oil ¡ Triglyceride ¡ Methanol ¡ Glycerol ¡ Methyl ¡Esters ¡ (Biodiesel) ¡ Tubular ¡Centrifuge ¡ Light ¡Liquid = ¡Glycerol-‑ ¡ Methanol ¡mixture ¡ Heavy ¡Liquid = ¡Biodiesel ¡

Cos-ng ¡ ¡ BIODIESEL ¡PRODUCTION ¡ ¡ 70,000,000 ¡L/year ¡ PRODUCTION ¡PERIOD ¡ 52 ¡weeks ¡a ¡year, ¡24/7 ¡ ¡ ANTICIPATED ¡SALES ¡ $49,421,000/year ¡ CAPITAL ¡COST ¡(MOTOR+CENTRIFUGE) ¡ $2,455,000 ¡ UTILITY ¡COSTS ¡(ONLY ¡ASSOCIATED ¡WITH ¡ $2,428/year ¡ MOTOR) ¡ INLET ¡FEED ¡COMPOSITION ¡ 60.2% ¡Biodiesel, ¡39.1% ¡Methanol, ¡0.7% ¡ Glycerol ¡ EXTRA ¡READING ¡OPPORTUNITIES: ¡ • Oh, ¡P., ¡Lik, ¡H., ¡Lau, ¡J.C., ¡Junghui, ¡C., ¡Chong, ¡M.F., ¡Choo, ¡Y.M. ¡ A ¡review ¡on ¡convenSonal ¡ technologies ¡and ¡emerging ¡process ¡intensificaSon ¡(PI) ¡methods ¡for ¡biodiesel ¡ producSon. ¡Renewable ¡and ¡Sustainable ¡Energy ¡Reviews ¡16(2012) ¡5131-‑5145 ¡ • Coulson, ¡J.M., ¡Harker, ¡J.H., ¡Backhurst, ¡J.R., ¡Richardson. ¡(2002). ¡ Coulson’s ¡and ¡ Richardson’s ¡Chemical ¡Engineering: ¡Par6cle ¡technology ¡and ¡separa6on ¡processes . ¡ Buberworth-‑Heinemann ¡

HF Alkylation – Process Overview

HF Alkylation – Costs Item Cost (C$) Column Total CapEx 5,381,000 Condenser Separator Inlet Operators 44,000 Steam 645,000 Side draw Light Oil HF Maintenance 161,000 Kettle Reboiler Electricity 93,000 Steam Total OpEx 943,000 Alkylate Condensate [1] G. Towler & R. Sinnot (2009), Chemical Engineering Design, 5 th Ed., Elsevier [2] R. Meyers (2004), Handbook of Petroleum Refining Processes, 3 rd Ed., McGraw-Hill

Production of Benzene from Hydrodealkylation of Toluene (Alaa Salam and Saeed Mobayed) Process Flow Diagram Reaction: Toluene + H 2 → Benzene + CH 4 (Irreversible reaction) 2 Benzene ⇌ Diphenyl + H 2 (By-product of the reaction) Separation Units: Flash drum, Three Distillation Columns ( Stabilizer, Benzene, Toluene) Physical Principle: Exploiting the boiling point of component

Estimated Costs of the Separation Process in HDA Production Rate of benzene : 265 mol/hr Value of benzene is : $ 9.04/mol Value of the produced Benzene in one year: $ 17,410,500 Cost Benzene Distillation Column 120,000 $ Benzene column Installation 20,000 $ Separation of (benzene) & (Toluene and 81,000 $/year (product) Cost diphenyl) Cooling Water 12,900 $/year Condenser 26,700 $/year Heat 20,800 $/ year Steam 102,600 $/year Total 384,000 $ /year Cost Toluene Distillation Column 85,000 $ Installation 15,000 $ Toluene Column Separation of Toluene & Diphenyl 26,300 $/year Cooling Water 2,600 $/year (recycling) Cost Condenser 6,500 $/year Heat 8,600 $/ year Steam 49,600 $/year Total 193,600 $/year The Grand Total of the Separation Process is: $ 672,800 / year References: [1]Richard Turton: Analysis, Synthesis and Design of Chemical Processes , Third Edition, (2008), Chapters 1-4. [2]Robert Perry; Don Green: Perry’s Chemical Engineers’ Handbook , Eighth Edition, McGraw-Hill, (2008), Chapter 13 Distillation

Disk Stack Centrifuge for Insulin Production By: Ushna Ikram Allen Winata Manufacturing Process of insulin Inside of a Disk Stack Centrifuge

Design and Cost Analysis Design parameters Design Equation N 120 r1 (m) 0.13 r2 (m) 0.08 (rpm) 6000 Angle 35 Sigma 35944.94 Equipment Cost - $155,000+/- 40% Operational Cost - $14,256/yr References: Leung, Wallace Woon-Fong. (2007). Centrifugal Separations in Biotechnology . Elsevier Science & Technology. Retrieved 14 November 2012 (Disk Stack Centrifuge) Petrides D. Bioprocess Design . 2000 (Insulin Process)

Uranium Recovery using Counter Current Solvent Exchange Stokes Law: 2 𝜍 𝑞 −𝜍 𝑔 𝑆 2 𝑤 𝑡 = 9𝜈

Operating Costs and Installation Element Cost Bare Module $543,000-$1,627,000 Agitator Costs $1247/yr Solvent Costs ($4.5/gal) $121,000/yr Total Operating Costs $122,000/yr Useful References: IAEA (1980). Technical Report Series No. 196. Significance of Mineralogy in the Development of Flowsheets for Processing Uranium Ore [Online]. Available: http://www-pub.iaea.org/MTCD/publications/PDF/trs196_web.pdf D. C. Seidel (1981). Vol . 32 No. 2. Extracting Uranium From its Ores [Online]. Available: http://www.iaea.org/Publications/Magazines/Bulletin/Bull232/23204882428.pdf

Decanter Centrifuge Thomas Oszustowicz Jordon Perry Unit Overview Capable of handling feed with significant solids concentration Ideal for solid-liquid separation processes Capable of three phase separation Solid cylindrical bowl, conical shaped Screw Conveyer, operated at differential speed Mass Balance on Solids: F – Feed S – Solids stream C – Clarified liquids stream

Annual Operating Costs Perry’s Chemical Engineering Handbook was used to obtain the purchase cost and energy usage for a typical decanter centrifuge, which are $160,000 and 30 hp respectively. The following table summarizes annual operating costs: *Using salvage value = $10,000 and an average life of 20 years **Assuming it runs 24 hours/day every day of the year with an energy cost of 8 cents. References: 1. Perry’s Chemical Engineering Handbook (Don Green and Robert Perry) 2. Decanter Centrifuge Handbook (Alan Records and Ken Sutherland)

Recommend

More recommend