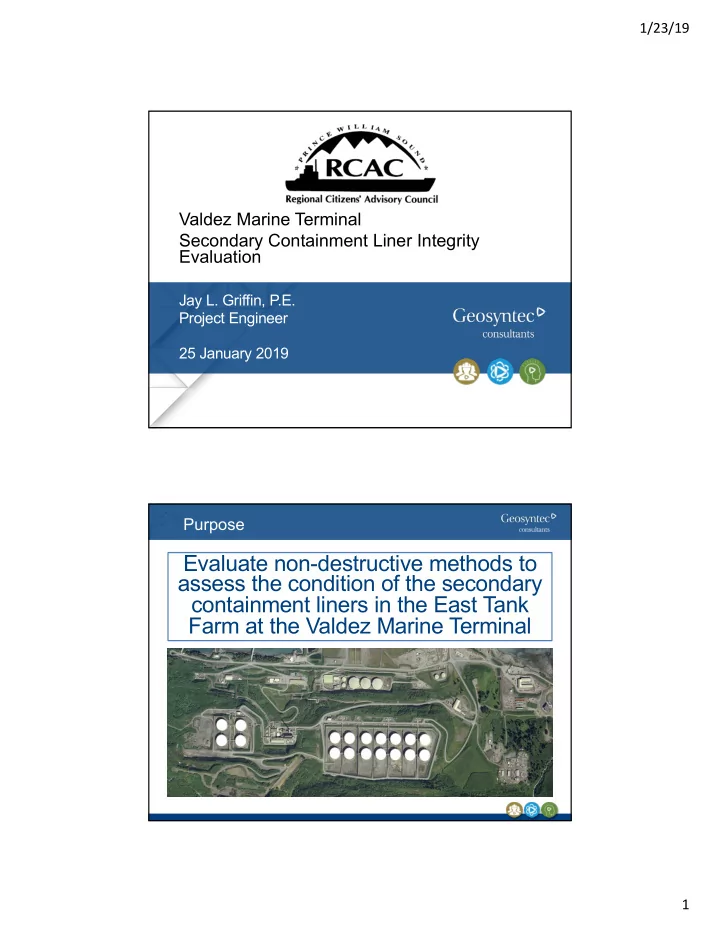

1/23/19 Valdez Marine Terminal Secondary Containment Liner Integrity Evaluation Jay L. Griffin, P .E. Project Engineer 25 January 2019 Purpose Evaluate non-destructive methods to assess the condition of the secondary containment liners in the East Tank Farm at the Valdez Marine Terminal 1

1/23/19 Secondary Containment Liner System 3/8” MINUS SOIL CBA Material Types CBA Hypalon XR-5 CBA Liner Provided by PWSRCAC 2

1/23/19 CBA Liner Golder, 2018 CBA Liner 3

1/23/19 CBA Liner Hypalon and XR-5 Hypalon Good UV resistance Good freeze-thaw flexibility Less compatible with hydrocarbons/fats XR-5 Good UV resistance Good freeze-thaw flexibility Compatible with chemicals and hydrocarbons 4

1/23/19 East Tank Farm Features • Foundations – Tank Ring Walls – Vertical Supports for Piping – Intercell Containment Walls • Draw Sumps • IWWS Manholes and Catch Basins • Piezometers • Environmental Remediation – Borings – Recovery/Vent Wells – Injection Points • Embankment Penetrations/ Concrete Terminations East Tank Farm Features 5

1/23/19 East Tank Farm Features Golder, 2018 East Tank Farm Features Golder, 2018 6

1/23/19 East Tank Farm Features Golder, 2018 East Tank Farm Features 7

1/23/19 Non-Destructive Methods Indirect, Inexact, and site-specific 1. Ground Penetrating Radar 2. Electromagnetics 3. Tracer Gas Testing 4. Electric Leak Location 5. Visual Inspection GPR and EM Ground Penetrating Radar Electromagnetics Source: www.kci.com Source: www.hgiworld.com 8

1/23/19 Tracer Gas Testing & ELL Tracer Gas Testing Utilized in many other industries No record of use for buried liner system Electric Leak Location Typical in waste containment and mining industries ASTM D 7007 – Covered Geomembrane Requires electrical isolation Variable resolution based on cover soil Cannot be performed in excessively wet conditions Tracer Gas Testing Smoke Machine and Blower Smoke 9

1/23/19 Electronic Leak Location Testing (INSULATOR) Source: ASTM D7007 Electronic Leak Location Testing Source: TRI and HGI 10

1/23/19 Costs • ELL = $12k to $15k per acre – Does not include engineering planning, support, and reporting – Does not include earthwork or isolation of subsurface features – Assumes no significant weather or logistical delays – Tracer gas testing likely similar cost Conclusions • Non-destructive leak location methods are inexact and site-specific • GPR/EM not technically feasible • Tracer Gas Testing technically feasible • ELL technically feasible • Recommend site-specific Pilot Study before full- scale implementation – could be performed in West Tank Farm 11

1/23/19 Thank You Questions? Jay L. Griffin, P .E. Project Engineer JLGriffin@geosyntec.com 510-285-2689 12

Recommend

More recommend