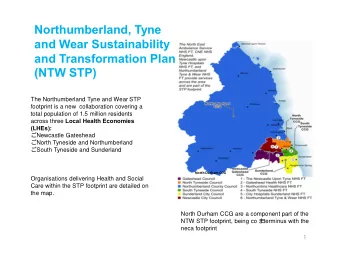

Energy Conservation Standards for Commercial & Industrial Fans - PowerPoint PPT Presentation

Energy Conservation Standards for Commercial & Industrial Fans and Blowers: Framework Public Meeting http://fileresource.sit epro.com/filemanage http://old.greenheck. r/207/imagecollection com/images/product s/1939/8948FC2F-

Authority & Definitions Authority and Background • Currently no energy conservation standards for commercial and industrial fans • Title III Part C of the Energy Policy and Conservation Act of 1975 (EPCA), as amended, sets forth various provisions designed to improve energy efficiency of commercial and industrial equipment. (42 U.S.C. 6311 – 6317) – Section 6311 includes a list of industrial equipment which the Secretary may classify as covered equipment • This list includes fans and blowers (42 U.S.C. 6311(2)(B)(ii) and (iii)) » Notice of Proposed Coverage Determination published June 28, 2011 (76 FR 37678) • Manufacturers must use a DOE prescribed test procedure to establish compliance with any standards set for commercial and industrial fans – In addition to energy conservation standards, DOE will undertake a test procedure rulemaking for commercial and industrial fans 20

Authority & Definitions Definitions • Currently there are no statutory definitions for fans and blowers – Framework Document discusses the considered definitions • DOE Proposed Definitions – • Commercial/Industrial Fan: A device used in commercial or industrial systems to provide a continuous flow of a gas, typically air, by an impeller fit to a shaft and bearing(s). A fan may be manufactured with or without a housing component. • Fan Manufacturer: An entity responsible for assembling a fan into a testable configuration such that the fan impeller is fit to a shaft, bearings, and in some cases installed within a housing component, • Axial Fan : A fan in which airflow enters and exits the impeller parallel to the shaft axis. The axial fan may or may not be equipped with a cylindrical housing, orifice panel/ring, inlet or outlet guide vanes 21

Authority & Definitions Definitions (cont.) • DOE Proposed Definitions (cont.) – • Centrifugal Fan : A fan in which airflow enters the impeller parallel to the shaft axis but changes direction and exits perpendicular to the shaft in a radial direction at the impeller discharge. The impeller may have one or two inlets and may or may not have a housing component. • Cross Flow Fan: A type of centrifugal fan in which the fluid path though the impeller is in a direction that is substantially at right angles to its axis with air both entering and leaving radially at its periphery • Mixed Flow Fan: A fan in which the direction of airflow through the impeller takes on characteristics that are intermediate between centrifugal and axial fans in that the air exits the fan in a direction which is neither parallel nor perpendicular to the shaft 22

Authority & Definitions Definitions (cont.) • DOE Proposed Definitions (cont.) – • Blower: An axial or centrifugal fan with a specific ratio between 1.11 and 1.20 were the specific ratio is the total pressure at the fan outlet divided by the total pressure at the fan inlet, measured at peak fan total efficiency (European Union 2011 Non-domestic fans legislation): – The term “blower” is used in many contexts by the industry, however, generally used to describe high pressure fans. DOE considers specific ratio a way to quantify “high pressure”. – AMCA 99 definition of blower emphasizes the application and not the specific technological features of the equipment • Safety Fan: An axial or centrifugal fan designed for use in applications requiring extra safety measures, such as: – Those designed to operate in potentially explosive atmospheres – Those designed for emergency use only, short-time duty, fire safety requirements – Those designed specifically to operate where gases temperature exceed 500ºF – Those designed in toxic, highly corrosive, or flammable environments. 23

Authority & Definitions Considered Fan Coverage • Fan Types – Inclusion of all fan types (axial, centrifugal, mixed flow, blowers) • Physical and Performance Criteria for Standards – Impeller Diameter: inclusion of fans up to 98 inches – Transmission Type: all – Rotational Speed: speeds up to 8,000 RPM 24

Authority & Definitions Request for Comment Item 2-1: DOE requests data on how fans are sold. Item 2-2: DOE requests comment on the suggested cross flow fan definition. Item 2-3: DOE requests comment on the suggested blower definition. Item 2-4: DOE requests comment on the suggested safety fans definition. Item 2-7: DOE requests comment on fan coverage as fans are defined in the Framework Document. 25

Public Meeting Agenda 1 1 Introduction Introduction 2 Rulemaking Process Overview 3 Authority & Definitions 4 Regulatory Regimes 5 Test Procedure & Efficiency Metrics 6 Rulemaking Analyses 7 Closing Remarks 26

Regulatory Regime Combined Fan, Motor, & Control Equipment • DOE is considering defining commercial and industrial fans as: – "a device used in commercial or industrial systems to provide a continuous flow of a gas, typically air, by an impeller for ventilation, circulation, or industrial process needs. A fan may be manufactured with a housing component, motor, drive, and/or a VSD". • Addressing losses besides the bare shaft fan – Example is in the EU Commission where they regulate non-domestic fans inclusive of motor & controls 27

Regulatory Regime Combined Fan Equipment (cont.) • VSDs are control devices – Enables the fan rotational speed to match process requirements • Benefits variable load applications and depends on time spent at various operating conditions • VSDs may not be appropriate for all applications and may degrade efficiency under constant load operation – Same fans can be used in constant and variable load applications • DOE is not aware of any specific fan type that is always used in an application that would benefit from a VSD • Manufacturers cannot control if or how a VSD is used – DOE will conduct analyses across the full spectrum of fan applications and baseline conditions to determine VSDs impact on the field energy use 28

Regulatory Regime Fans For Which DOE is Considering Standards • Bare Shaft Fans: Fans without drives, attachments, or accessories – Regulatory Regime #1: single set of equipment classes • Bare shaft fan regulatory approach for all fan types regardless of how they are sold • Combined Fan Equipment: Fan+Motor or Fan+Motor+VSD – Regulatory Regime #2: two sets of equipment classes • Fans without VSD (sold with or without motor) • Fans with VSD – Regulatory Regime #3 : two sets of equipment classes • Fans without motor • Fans with motor (sold with or without VSD), VSD is a design option to increase efficiency 29

Regulatory Regime Request for Comment Item 2-9: DOE requests comment on whether establishing standards for fans defined inclusive of the motor, transmission, and controls could increase the benefits of using VSDs in the field. Item 2-10: DOE requests data and comment on whether fans are more often combined with motors, VSDs, or both by the fan manufacturer or by distributors/contractors. Item 2-11: DOE requests information on how often and in what circumstances the intended application is known when the fan is sold. Item 2-12: DOE seeks comment on whether to consider establishing standards only for fans with diameters below a certain maximum and/or above a certain minimum. 30

Regulatory Regime Request for Comment Item 2-14: DOE requests comment on covering fans+motors with motor power requirements between 125 W and 500 kW for this rulemaking. Item 2-16: DOE requests comment on what percentage of fan motors are covered by the small and medium electric motor standards. Item 2-17: DOE seeks comment on the market share (by fan type) and applications of fans that are driven by equipment other than electric motors. Item 2-18: DOE requests comment on fan transmission types. Item 2-19: DOE requests comment on the VSDs sold with fans and whether there is efficiency variability (and if so, to what extent) among VSDs. 31

Public Meeting Agenda 1 1 Introduction Introduction 2 Rulemaking Process Overview 3 Authority & Definitions 4 Regulatory Regimes 5 Test Procedure & Efficiency Metrics 6 Rulemaking Analyses 7 Closing Remarks 32

Test Procedure & Efficiency Metrics Test Procedures • DOE is developing a test procedure for commercial and industrial fans. • When establishing test procedures, DOE reviews existing industry test procedures to measure the energy use or efficiency of the covered equipment as a starting point in the process. • Manufacturers must use DOE test procedures to ensure compliance with the standards and to make representations of the energy use of the covered equipment. 33

Test Procedure & Efficiency Metrics Current Industry Test Procedures • ANSI/AMCA 210-07 / ANSI/ASHRAE 51- 07: “Laboratory Methods of Testing Fans for Aerodynamic Performance Rating” • Applicable to all fan types • Widely recognized and utilized in U.S. • AMCA Standard 220 “Laboratory Methods of Testing Air Curtain Units for Aerodynamic Performance Rating” • Includes modifications for AMCA 210 for air curtain testing. • ISO 5801- 07 “Industrial fans - Performance testing using standardized airways” • International standard developed based on standards: AMCA 210, BS 848 Part 1:1980 (U.K.) and DIN 24163-2: 1985 (Germany) 34

Test Procedure & Efficiency Metrics Potential Test Configurations Considered • Defines the use and geometry of connections to a fan outlet and/or inlet. • There are four test configurations (also referred to as installation categories) specified in ISO 5801 and AMCA 210-07: Installation Category/ Location of Ducting for Testing Test Configuration A Free inlet, free outlet B Free inlet, ducted outlet C Ducted inlet, free outlet D Ducted inlet, ducted outlet • DOE is considering specifying a single test configuration per equipment class for consistency of results since ducting impacts fan performance. 35

Test Procedure & Efficiency Metrics Request for Comment Item 3-1: DOE requests comment on the use of the AMCA 210-07 test procedure as a base for the development of a DOE test procedure. Item 3-3: DOE requests comment on AMCA Standard 220-05 for measuring performance of cross flow fans. Item 3-6: DOE requests comment on using a clean air only test procedure for dust air or material handling fans. 36

Test Procedure & Efficiency Metrics Request for Comment Item 3-7: DOE requests comment on which test configuration should be considered for each of the considered equipment classes (axial housed, axial un-housed, centrifugal clean air housed, centrifugal clean air unhoused, centrifugal dust air, centrifugal material handling, centrifugal cross flow, mixed flow, blowers, safety fans). Item 3-8: DOE requests comment on requiring an air straightener to reduce air swirl at the outlet for axial fans tested in configuration B (free inlet, ducted outlet) or D (ducted inlet, ducted outlet). 37

Test Procedure & Efficiency Metrics Currently Available Fan Efficiency Data & Definitions • Sources – Information from manufacturer websites and catalogs . • Efficiency Definitions – Peak Total Efficiency (AMCA 99) • Ratio of fan air power output to fan shaft power input for the operating condition for which this value is highest. – Overall Efficiency (ISO 12759) • Fan peak total efficiency multiplied by drive components efficiency (includes efficiency of motor and any components between the motor and the power supply and any mechanical devices between motor and fan). • Each fan and motor combination has a unique efficiency value. 38

Test Procedure & Efficiency Metrics Potential Efficiency Metric Considered for Bare Shaft Fans • Fan Efficiency Grades (FEG) per AMCA 205-10 (Rev. 2012) – Numerical rating that represents fan efficiency – Each FEG represents a relationship of peak total efficiency as a function of a fan's impeller diameter – DOE plans to evaluate an FEG metric by developing fan efficiency grades unique to each equipment class 39

Test Procedure & Efficiency Metrics Potential Efficiency Metric Considered for Bare Shaft Fans (cont.) • DOE is interested in expanding the FEG approach to incorporate operational conditions of a fan – DOE would evaluate efficiency against combinations of size and operational parameters, for example, diameter and specific speed * *Specific speed is a function of a fan’s airflow, rotational speed, and pressure . 40

Test Procedure & Efficiency Metrics Expanded FEG - Example 100 30 40 90 50 60 70 80 80 Total Efficiency (%) 100 70 60 50 40 30 60000 50000 Specific Speed Ns 40000 80 30000 60 20000 40 10000 20 Impeller Diameter (inch) 41

Test Procedure & Efficiency Metrics Expanded FEG Efficiency Metric - Example Specific Speed 90% 10000 11833 80% 13667 15500 17333 70% 19167 Total Efficiency (%) 21000 22833 24667 60% 26500 28333 30167 50% 32000 33833 35667 40% 37500 39333 41167 30% 0 10 20 30 40 50 60 70 80 90 100 43000 Impeller Diameter (inches) 42

Test Procedure & Efficiency Metrics Efficiency Metric for Fans Inclusive of Motor & Controls • Efficiency may need to include motor power to reflect energy-efficiency changes for fan-motor systems. • DOE would consider a metric that can be used to account for the use of more efficient VSDs. • DOE would consider a metric that can capture the energy impacts from using a VSD in comparison to a fan with a motor but without a VSD. • Example: European Union’s Fan -Motor Efficiency Grade (FMEG) – Uses overall efficiency with a VSD compensation factor. 43

Test Procedure & Efficiency Metrics Efficiency Metric for Fans Inclusive of Motor & Controls (cont.) • If DOE pursues an regulatory regime for fans inclusive of the motor & controls, then two sets of equipment classes will be developed - may require different efficiency metrics for each set • Separate metrics: – DOE would use different metrics for the two equipment class sets – Would not allow direct comparison of fan efficiency when comparing bare shaft fans vs. fans with additional components • Same metrics: – DOE would use the same efficiency metric for both equipment class sets – Would allow direct comparison of fan efficiency across the equipment class sets 44

Test Procedure & Efficiency Metrics Regulatory Regimes and Efficiency Metric Options for Equipment Class Sets Summary Table Metric Alignment Options Regulatory Regime Equipment Class Set Separate Same Multiple Only one set of 1 Bare Shaft fans N/A N/A N/A equipment classes Overall Efficiency Fans Without VSD Fan Peak Total (with or without (standardized N/A Efficiency motor) motor and VSD) Fans inclusive of the 2 motor and VSD Fan Peak Total Overall Fans With VSD Overall Efficiency Efficiency and Overall Efficiency Efficiency Motor Input Power Fan Peak Total Based Bare Shaft Fans N/A Efficiency (standardized motor) 3 Fans inclusive of motor Fan Peak Total Fans With Motor Electric Input Electric Input Efficiency and Electric (with or without VSD) Power Based Power Based Input Power Based Metric 45

Test Procedure & Efficiency Metrics Request for Comment Item 3-9: DOE requests comment on the appropriateness of using publicly available performance data in lieu of original test data Item 3-10: DOE requests original fan performance data generated from AMCA 210 tests Item 3-11a: DOE requests comment on the considered efficiency metric approaches for bare shaft fans Item 3-11b: DOE requests comment on the EU’s FMEG efficiency metric for fans sold with motors 46

Test Procedure & Efficiency Metrics Request for Comment Item 3-11c: DOE requests comment on the use of overall efficiency for fans sold with both motors and VSDs Item 3-18: DOE requests comment on the use of input power based efficiency for fans sold with motors Item 3-19: DOE requests comment on whether fans that perform under variable load conditions should be required to meet multiple standards Item 3-20: DOE seeks comment on setting standards based on different efficiency metrics for fans sold alone and fans sold with motors & VSDs 47

Public Meeting Agenda 1 Introduction 2 Rulemaking Process Overview 3 Authority & Definitions 4 Regulatory Regimes 5 Test Procedure & Efficiency Metrics 6 Rulemaking Analyses 7 Closing Remarks 48

Preliminary Analysis Framework Final Preliminary Effective NOPR Document Rule Analysis Date Market & Markups for Technology Product Engineering Price Analysis Screening Determination Analysis Life-Cycle Cost and Payback Period Analysis National Energy Use Impact Analysis Analysis Preliminary Shipments Manufacturer Impact Analysis Analysis 49

Market and Technology Assessment • Purpose: – Characterize the commercial and industrial fan markets and the measures to improve efficiency. • Method: – Identify and characterize manufacturers of commercial and industrial fans – Estimate shipments and trends in the market – Identify technologies that could improve efficiency – Identify regulatory and non-regulatory initiatives intended to improve the efficiency of the equipment covered under this rulemaking 50

Market and Technology Assessment Considered Commercial and Industrial Fan Equipment Classes, Bare Shaft* Fan Type Equipment Class Housed Axial Unhoused Safety Fans Clean Air Housed Clean Air Unhoused Dust Air Housed Centrifugal Material Handling Housed Cross Flow Housed Safety Fans Mixed Flow All Axial Blowers Centrifugal *Note: If DOE uses regulatory option #2 or #3, a second set of equipment classes could be developed that mirror the set shown for bare shaft fans. 51

Market and Technology Assessment Technology Options to Improve Efficiency Bare Shaft Fans • Improving aerodynamic design • Blade shape • Material selection • Guide vanes • Optimization of housing design Fans Sold with Motors/VSD • Improved motor efficiency • Variable speed drive • Improved variable speed design 52

Market and Technology Assessment Request for Comment Item 5-1: DOE requests information that would contribute to the market assessment for fans. Examples of information sought include current equipment features, efficiencies and efficiency trends, historical shipments and prices by equipment class. Item 5-2: DOE requests comment on the estimates of the number of U.S. fan manufacturers that could be considered small businesses. 53

Market and Technology Assessment Request for Comment Item 5-3: DOE welcomes comments on performance-related features DOE should consider when defining fan equipment classes. Item 5-5: DOE requests comment on whether transmission type should be considered when determining equipment classes. Item 5-6: DOE requests comment on whether the development of separate equipment classes is necessary to accommodate different performance characteristics of fans sold bare shaft versus fans sold with the motor, transmission, and/or controls. Item 5-7: DOE requests comment on splitting axial fan types into housed and unhoused equipment classes or whether a single equipment class would sufficiently represent axial fan applications. Item 5-8: DOE requests comment on what types of axial fan designs or characteristics are unique to axial-type safety fans. Item 5-9: DOE requests comment on whether there are any other commercial or industrial applications (beyond clean air, dust air and material handling) that should be considered while defining equipment classes for centrifugal fans. 54

Market and Technology Assessment Request for Comment Item 5-10: DOE requests comment on the considered groupings of housed centrifugal fans. Specifically, DOE requests comment on the use of air quality (Clean Air, Dust Air, Material Handling) and housing characteristics for classification purposes. Item 5-11: DOE requests comment on setting cross flow fans as a separate equipment class within the centrifugal fans category. Item 5-13: DOE requests comment on what types of centrifugal fan designs or characteristics are unique to centrifugal-type safety fans. Item 5-14: DOE requests comment on setting a separate equipment class for blowers. Item 5-15: DOE requests comment on whether there is a need of more than one blower equipment class to account for the differences between centrifugal and axial blowers. Item 5-16: DOE requests comment on setting a separate equipment class for mixed flow fans. Item 5-17: DOE requests comment on whether there are differences among mixed flow fans that might warrant more than one equipment class for this fan type. 55

Market and Technology Assessment Request for Comment Item 5-18: DOE requests comment and/or information on the effect of different blade materials on efficiency. Item 5-20: DOE requests comment on whether there are compatibility issues with certain fans and VSDs that DOE should be aware of when considering a VSD as a means to improve fan efficiency. Item 5-21: DOE welcomes comments on the preliminary technology options identified in the Framework and whether there are other technology options it should consider. 56

Preliminary Analysis Framework Final Effective Preliminary NOPR Document Rule Analysis Date Market & Markups for Technology Product Engineering Price Analysis Screening Determination Analysis Life-Cycle Cost and Payback Period Analysis National Energy Use Impact Analysis Analysis Preliminary Shipments Manufacturer Analysis Impact Analysis 57

Screening Analysis • Purpose: – Screen out technology options that DOE will not consider in the engineering analysis for commercial and industrial fans • Method: – DOE will evaluate each technology option based on the following criteria: • Technological feasibility • Practicability to manufacture, install and service – Note: practicability is on a commercial scale at the compliance date of any final standards • Impacts on product utility or available to consumers • Impact on health and safety 58

Screening Analysis Request for Comment Item 6-1: Are there any technologies that DOE should not consider because of any of the four screening criteria? If so, which screening criteria apply to the cited technology or technologies? 59

Preliminary Analysis Framework Final Effective Preliminary NOPR Document Rule Analysis Date Market & Markups for Technology Product Engineering Price Analysis Screening Determination Analysis Life-Cycle Cost and Payback Period Analysis National Energy Use Impact Analysis Analysis Preliminary Shipments Manufacturer Analysis Impact Analysis 60

Engineering Analysis Engineering Analysis – Purpose • Develop the cost-efficiency curve, which characterizes the relationship between manufacturer selling price (MSP) and energy efficiency. • The cost-efficiency curves for the examined equipment classes are key inputs for the downstream rulemaking analyses. Manufacturer Selling Price – Rulemaking Analyses Efficiency Relationship • Life-Cycle Cost and Payback Selling Price (MSP) Manufacturer Period Analysis • Manufacturer Impact Analysis • Employment Impact Analysis Efficiency Level 61

Engineering Analysis Representative Equipment Classes and Representative Units • The equipment classes identified by DOE cover a range of fan designs and allow for a wide range of fan sizes. • DOE may focus its analysis on a subset of representative equipment classes and a representative group of units within these classes. 62

Engineering Analysis Requests for Comment Item 7-1 Once DOE establishes any representative equipment classes and representative units, it selects a baseline model as a reference point for each representative unit from which to measure changes resulting from the design options. DOE develops separate engineering analyses for each baseline model analyzed. DOE intends to use fan teardowns and fan efficiency (determined from fan performance tests) to develop cost-efficiency relationships for the fans analyzed. DOE intends to develop the necessary test procedures through a test procedure rulemaking. Item 7-2 DOE seeks input on the methods and approaches used by manufacturers to improve the efficiency of fans. Item 7-3 DOE welcomes comment from interested parties on the best methodology for scaling the representative units to other fan sized within the equipment class. 63

Engineering Analysis Data Sources • DOE may use publicly available data from manufacturer websites and catalogs, but such information may be limited. Request for Comment Item 7-4 DOE seeks fan test data to improve DOE’s understanding of fan performance to select appropriate representative units for the respective equipment classes. 64

Engineering Analysis Engineering Analysis Methodology Define Baseline • Determine characteristics of common or typical models which will serve as reference points to assess changes due to energy Models conservation standards. • Conduct tests to verify efficiency ratings. • Perform equipment disassembly to identify design options and Reverse-Engineering provide input to manufacturing cost models to determine designs and costs associated with each efficiency level. Data Collection, & • Collect manufacturer cost data on efficient fan designs. • Conduct interviews with manufacturers to enhance understanding of Interviews efficiency improvements and associated costs. Develop Engineering • Develop cost-efficiency curves based on reverse-engineering and cost data from available sources including manufacturer interviews. Analysis Curves 65

Engineering Analysis Reverse-Engineering Methodology Selection of Units Physical Teardown Bill of Materials Fabricated Purchased Parts Parts Assembly Process Manufacturer Costs 66

Engineering Analysis Requests for Comment Item 7-5 For each equipment class, DOE welcomes stakeholder comments on methods and approaches that DOE intends to employ to determine potential fan efficiency improvements. Detailed information on fan performance and the incremental manufacturing costs (e.g., material costs, labor costs, overhead costs , building conversion capital expenditures, tooling/equipment conversion capital expenditures associated with more efficient designs, research and development (R&D) expenses, and marketing expenses) would be useful. 67

Engineering Analysis Manufacturing Selling Price (MSP) • MSP includes manufacturer production costs (MPC) as well as non- production costs, such as maintenance, depreciation, and taxes. • Markups will be used to represent non-production costs and convert the MPC to the MSP. • DOE intends to estimate manufacturer markups based on publicly available financial information and manufacturer interviews. Requests for Comment Item 7-6 DOE welcomes comment on the markup approach proposed for developing estimates of manufacturer selling prices. Item 7-7 DOE welcomes comment on the proposed approach to determine the relationship between manufacturer selling prices and fan efficiency. 68

Engineering Analysis Conversion Costs • Includes the difference in investments required to build production facilities required for higher-efficiency designs as compared with investments for production facilities used for current designs. • DOE typically does not include conversion costs in the engineering analysis. • One option to improve fan efficiency is re-design. The non-recurring R&D costs required to develop such new designs also would not be part of the MSP calculated in the engineering analysis. It will be addressed in the Manufacturer Impact Analysis. Requests for Comment Item 7-8 DOE welcomes comment on the conversion costs required to improve the efficiency of the fans to various levels, as well as what portion of these costs would be passed on to the consumer. 69

Engineering Analysis Selecting Representative Units and Scaling Results • Within each representative equipment class, DOE would select representative unit fans in size ranges and of specific speed values that represent a large number of models. • DOE would also plan to evaluate fans of small and large sizes for at least one fan series to characterize a size-efficiency relationship. • DOE would use this relationship to scale results for representative units to smaller and larger units. 70

Engineering Analysis Request for Comment Item 7-9: DOE requests comment on limiting representative unit selection to fan size(s) that include the most available units. Item 7-10: DOE requests comment on the selection of additional fans at both larger and smaller sizes to determine a fan size-efficiency scaling relationship. DOE requests comment on the number of additional fans to test to develop the size-efficiency scaling relationship. 71

Engineering Analysis Baseline Models • DOE typically selects models that just meet current energy conservation standards to represent the baseline. • Energy conservation standards for fans do not currently exist. Hence, for this rulemaking, DOE will select baseline models at the bottom-of-market efficiency representing substantial shipments. 72

Engineering Analysis Request for Comment Item 7-12: DOE seeks comment on the selection, appropriate features, and performance characteristics of baseline models for each equipment class. Specifically, DOE requests comment on choosing the least efficient fan design as the baseline model for the equipment class. DOE will define the characteristics of the proposed baseline models based on comments from interested parties in addition to DOE's analysis. 73

Engineering Analysis Efficiency Levels • Within a given size selected for analysis, the fan models for which performance data is available will be assessed to determine efficiency levels for analysis. Requests for Comment Item 7-1 DOE requests comment on the method of using fan unit efficiencies as the basis for determining efficiency levels. 74

Engineering Analysis Efficiency Levels (cont.) • Once DOE establishes a baseline for each representative unit, it establishes efficiency levels based on measured improvements in efficiency resulting from implementation of technology options. DOE will develop separate engineering analyses for each baseline model analyzed. • • DOE intends to determine fan efficiency from fan performance tests performed using the proposed DOE test procedure. 75

Engineering Analysis Request for Comment Item 7-14: DOE seeks input from interested parties regarding the range of efficiency levels that should be examined as part of its analysis. Item 7-15: DOE requests comment on whether manufacturers generally do not offer fans of varying efficiencies that meet the same duty requirement. 76

Engineering Analysis Max Tech • DOE is required to analyze maximum technologically feasible (“max tech”) efficiency levels. • DOE will seek interested party input on the appropriate max tech levels. Requests for Comment Item 7-1A DOE welcomes inputs from interested parties on a methodology that would be appropriate for determining the max-tech models for each fan analyzed. 77

Engineering Analysis Outside Regulatory Changes • DOE will consider the effects of other DOE energy conservation standards and regulatory changes outside DOE’s rulemaking process that can impact manufacturers of covered equipment. • Some regulatory changes can also affect the efficiency or energy consumption of the fans covered under this rulemaking. • DOE will attempt to identify any outside engineering issues that could impact the engineering analysis. Request for Comment Item 7-16: DOE welcomes comment on whether there are outside regulatory changes that DOE should consider in its engineering analysis of fans. 78

Preliminary Analysis Framework Final Effective Preliminary NOPR Document Rule Analysis Date Market & Markups for Technology Product Engineering Price Analysis Screening Determination Analysis Life-Cycle Cost and Payback Period Analysis National Energy Use Impact Analysis Analysis Preliminary Shipments Manufacturer Analysis Impact Analysis 79

Markups Analysis • Purpose: – Estimate actual user prices from manufacturer selling prices of baseline and higher efficiency designs of equipment • Method: – Identify distribution channels and estimate share of each channel in the aggregate sales volume – Estimate how equipment is marked up along each level of the distribution chain 80

Markups Analysis Proposed Distribution Channels Manufacturer OEM OEM Product Distributor User (OEM Channel-A) Manufacturer D istributor Contractor User (Distributor Channel -B) Manufacturer D istributor User (Distributor Channel-C) Manufacturer User (Direct End-User Channel-D) Manufacturer Representatives Manufacturer Other User (Channel-E) Figure 1. Commercial and Industrial Fan Distribution Channels 81

Markups Analysis Types of Markups in Distribution Chain • Baseline Markups: - Markups relate end-user price to manufacturers selling price (MSP) averaged over all distribution channels. - Baseline markups relate price to MSP for all currently sold equipment. - Baseline markups indicate a consumer price that covers all of a distributor’s or contractor’s current expenses plus profit. • Incremental Markups: - Incremental markups relate the incremental change in end-user price to the incremental change in MSP due to higher efficiency designs. - Some of the distributor’s costs, such as direct labor costs (salaries, payroll, rental and occupancy), do not vary with efficiency induced changes and are excluded from the calculation of incremental markups. - Incremental markups cover only expenses that are expected to vary with higher cost of equipment sold e.g., business promotion, interest and insurance etc. 82

Markups Analysis Mark-Ups Analysis Request for Comment Item 8-1: DOE requests information regarding the functioning of the manufacturer representatives/distributors for different equipment classes and market segments. Item 8-2: DOE requests information on OEM market segments, and the downstream distributor channels, if any. Item 8-3: DOE requests comments on the applications and market segments identified by interested parties and information on other market segments, including their corresponding distributor channel(s) and the trade association(s) representing the distributors. 83

Markups Analysis Mark-Ups Analysis Request for Comment Item 8-4: DOE requests information on the proposed distribution channels and the share of industry shipments expected for each distribution channel for the commercial and industrial fans in terms of either each specific equipment class or the broader equipment categories described above. Item 8-5: DOE seeks comment on other sources of relevant data that could be used to characterize markups for commercial and industrial fans. Item 8-6: DOE requests feedback on its proposal to use incremental distribution channel markups for the LCC analysis. 84

Preliminary Analysis Framework Final Preliminary Effective NOPR Document Rule Analysis Date Market & Markups for Technology Product Engineering Price Analysis Screening Determination Analysis Life-Cycle Cost and Payback Period Analysis National Energy Use Impact Analysis Analysis Preliminary Shipments Manufacturer Impact Analysis Analysis 85

Energy Use Analysis • Purpose: – Identify how fans are actually operated by users and to determine the energy savings potential of more efficient designs in the field – Estimate annual energy consumption (AEC) for baseline and higher-efficiency designs • Issues: – End-use load profiles are expected to be highly variable across equipment classes and applications – In practice many, if not all, fans typically operate at points other than their peak efficiency – Useful work done by any fan will vary widely across a range of possible applications 86

Energy Use Analysis Approach • Estimate annual energy consumption (AEC) for baseline and higher- efficiency designs using use the load profiles developed for each All _ operating _ po int s kW application: All _ operating _ po int s AEC 0 kW . 746 ( H / ) N fan overall i i AEC 0 . 746 ( H / ) N HP fan overall i 1 i i HP i 1 Where: Where: AEC = annual energy consumption (kWh) H fan AEC = annual energy consumption (kWh) 𝐼 𝑔𝑏𝑜 = air horsepower at the operating point i 𝐼 𝑔𝑏𝑜 = air horsepower at the operating point i N i = operating hours at the operating point i η Overall =η F × η T × η M × η C at the operating point i N i = operating hours at the operating point i η F = fan efficiency η Overall =η F × η T × η M × η C at the operating point i η T = transmission efficiency η F = fan efficiency η M = motor efficiency η T = transmission efficiency η C = control system efficiency η M = motor efficiency • Develop statistical models describing the expected range of duty profiles η C = control system efficiency for fans in different applications 87

Energy Use Analysis Request for Comment Item 9-1: DOE requests input and recommendations for identifying high sales volume and large installed base market segments corresponding to specific industries and specific applications for which the fan equipment may have similar load profiles. Item 9-2: DOE welcomes recommendations on sources of data or analysis methods that would provide end-use load profiles for each of the commercial and industrial fans in the different market segments. Item 9-3: DOE requests input on ways to characterize fan sizing and selection practices for different equipment classes and applications and to help define the design or peak fan load for the purpose of generating normalized load profiles Item 9-4: DOE welcomes comment on methods for determining generic (non-market segment specific) load profiles for fan equipment classes considered in this rulemaking. 88

Energy Use Analysis Request for Comment Item 9-5: DOE welcomes comment on the current penetration level of variable-speed drives in the installed base of products or applications for each of the equipment classes considered in this rulemaking. Item 9-7: DOE requests comment and recommendations on the range of and number of fan rotation speeds over which the analysis should be carried out for different equipment classes. Item 9-8: DOE requests information on current industry practices and recommendations on the selection of representative operating points for a given rotational speed. DOE welcomes comment on whether the analysis should be extended to a range of operating points away from the peak efficiency. Item 9-9: DOE requests comment and estimates to establish the mean value and the ranges of likely values for motor, transmission, and motor control efficiencies. 89

Preliminary Analysis Framework Final Effective Preliminary NOPR Document Rule Analysis Date Market & Markups for Technology Product Engineering Price Analysis Screening Determination Analysis Life-Cycle Cost and Payback Period Analysis National Energy Use Impact Analysis Analysis Preliminary Shipments Manufacturer Analysis Impact Analysis 90

Life-Cycle Cost and Payback Period Analysis • Purpose: – Assess life-cycle cost (LCC) impacts of different efficiency levels on the consumer • Method: – LCC equals consumer price plus the sum of annual operating costs (including repair and maintenance costs) discounted to a particular base year – Economic evaluation from the consumer perspective – Results are expressed as LCC difference (base case minus higher efficiency level) – Payback Period (PBP) is also calculated and reported in this analysis 91

Life-Cycle Cost and Payback Period Analysis Approach • For each of the representative units in each equipment class: – Develop fan selection process to reflect product choices by customers – Develop distribution of equipment efficiencies expected for the compliance year – Aggregate the annual energy consumption over a fan’s lifetime – Model uncertainty and variability in the inputs using a Monte Carlo simulation method and probability distributions – Perform an analysis to determine whether the three-year rebuttable presumption of economic justification applies 92

Life-Cycle Cost and Payback Period Analysis Approach • Installation Costs – Consists of labor and any miscellaneous materials and parts. • Energy Prices – DOE will collect information about commercial and industrial electricity tariffs as a means of establishing marginal electricity prices. – DOE will use EIA’s Annual Energy Outlook to estimate future energy prices. • Maintenance & Repair Costs – DOE plans to consider maintenance and repair costs and plans to determine whether it changes with increased efficiency. 93

Life-Cycle Cost and Payback Period Analysis Approach • Equipment Lifetime – The operational lifetime of a fan can be determined from the number of revolutions until failure. – Revolutions until failure are usually limited by the fan’s bearing. – Basic bearing lifetime for medium-sized light duty fans is approximately 40,000 hours; for heavy duty fans is approximately 100,000 hours*. • A fan operating full-time is estimated to run 4,000 hours per year, translating into a fan lifetime of 10-25 years. • The RSMeans method uses an average fan lifetime of 15 years. *Source: Cory, W.T.W., Fans and Ventilation: A practical guide . 94

Life-Cycle Cost and Payback Period Analysis Approach • Discount Rates – DOE will derive the discount rates for the commercial and industrial users by estimating the capital costs for companies that purchase fans • Base Case Efficiency – Used to characterize the commercial and industrial fan market in the compliance year in the absence of DOE standards – If market share efficiency data are not available, DOE may develop efficiency distributions based on available models and information from fan manufacturers and experts 95

Life-Cycle Cost and Payback Period Analysis Request for Comment Item 10-1: DOE welcomes comment on the factors that impact the installation costs for fans and on whether installation cost increases with higher-efficiency equipment. Item 10-2: DOE welcomes input on the proposed methodology for estimating current and future electricity prices. Item 10-3: DOE invites comment on how repair costs may change for more efficient fans. DOE also invites comment on repair practices, and how usage patterns may impact equipment repair and maintenance. Item 10-4: DOE welcomes information that will assist in determining an appropriate distribution of fan lifetimes for the equipment classes covered in this rulemaking. Item 10-5: DOE welcomes input on the proposed approaches for estimating discount rates for fan users. Item 10-6: DOE requests data on the efficiency distribution and welcomes comment on the likelihood and degree of improvement in efficiency of commercial and industrial fans in the next 5 to 10 years as a result of market forces or industry trends. 96

Preliminary Analysis Framework Final Preliminary Effective NOPR Document Rule Analysis Date Market & Markups for Technology Product Engineering Price Analysis Screening Determination Analysis Life-Cycle Cost and Payback Period Analysis National Energy Use Impact Analysis Analysis Preliminary Shipments Manufacturer Impact Analysis Analysis 97

Shipments Analysis • Purpose: – Project future shipments by equipment class • Approach: – DOE typically projects shipments for a 30-year period beginning in the expected compliance date of the standard – Characterize the production of fans by using • Gross Domestic Product (GDP) as an indicator of the performance of industrial and commercial sectors where fans are used • Private fixed investment data for equipment incorporating fans from the U.S. Department of Commerce’s Bureau of Economic Analysis – DOE may use different shipments projection in the standards case as compared to the base case 98

Shipments Analysis Shipments Analysis Request for Comment Item 11-1: DOE welcomes comment on the shipments projection methodology. DOE invites comments regarding the selection of appropriate economic drivers and sources of data for historical shipments and shipment breakdowns by equipment class. Item 11-2: DOE requests historical shipments data for each of the considered equipment classes. Item 11-3: DOE welcomes comment on how an energy conservation standard for fans might impact shipments of the equipment covered in this rulemaking. 99

Preliminary Analysis Framework Final Preliminary Effective NOPR Document Rule Analysis Date Market & Markups for Technology Product Engineering Price Analysis Screening Determination Analysis Life-Cycle Cost and Payback Period Analysis National Energy Use Impact Analysis Analysis Preliminary Shipments Manufacturer Impact Analysis Analysis 100

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.