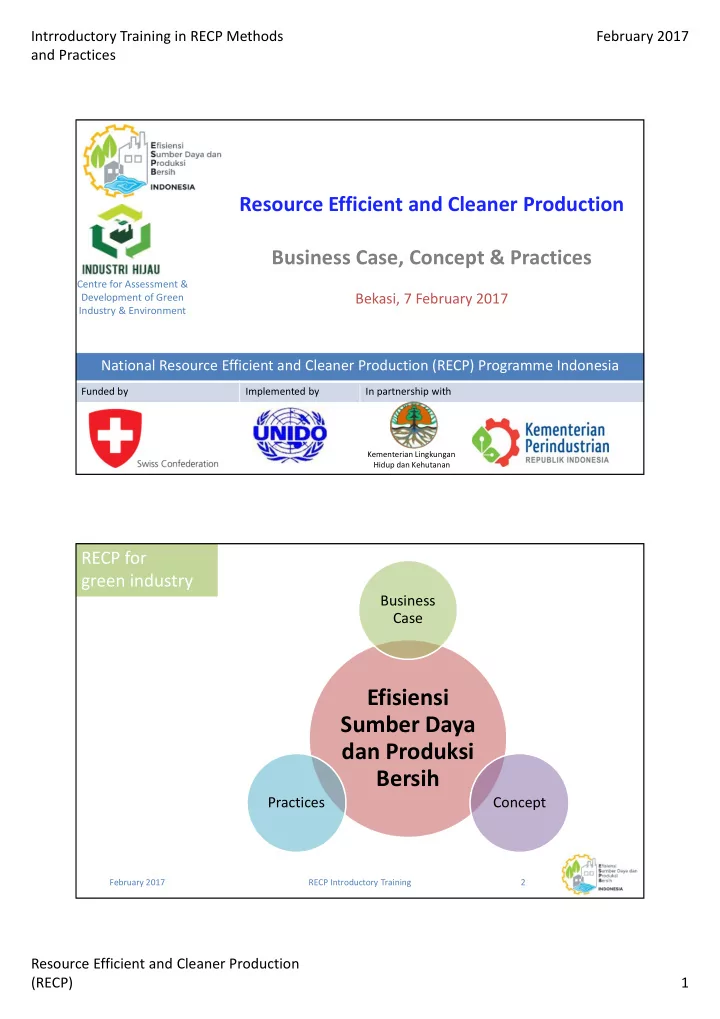

Intrroductory Training in RECP Methods February 2017 and Practices Resource Efficient and Cleaner Production Business Case, Concept & Practices Centre for Assessment & Development of Green Bekasi, 7 February 2017 Industry & Environment National Resource Efficient and Cleaner Production (RECP) Programme Indonesia Funded by Implemented by In partnership with Kementerian Lingkungan February 2017 RECP Introductory Training 1 Hidup dan Kehutanan RECP for green industry Business Case Efisiensi Sumber Daya dan Produksi Bersih Practices Concept February 2017 RECP Introductory Training 2 Resource Efficient and Cleaner Production (RECP) 1

Intrroductory Training in RECP Methods February 2017 and Practices Resource Efficient and Cleaner Production can in multiple ways improve productivity and competitiveness of enterprises in manufacturing and related productive sectors February 2017 RECP Introductory Training 3 Rathkerewwa Desiccated Coconut Industry National Cleaner Production Centre Sri Lanka February 2017 RECP Introductory Training 4 Resource Efficient and Cleaner Production (RECP) 2

Intrroductory Training in RECP Methods February 2017 and Practices RECP@ Chea Hap Rice Mill February 2017 RECP Introductory Training 5 Small Scale Rice Mills • Typical energy saving options – Individual drive system – Efficient separator – Efficient paddy cleaner – Plastic buckets in elevators – Voltage stabilizers – Energy efficient motors • Low cost options with pay back of 18 – 24 months Bureau of Energy Efficiency (n.d.), Manual on Energy Conservation Measures in Rice Mills cluster of Ganjam, Delhi, India February 2017 RECP Introductory Training 6 Resource Efficient and Cleaner Production (RECP) 3

Intrroductory Training in RECP Methods February 2017 and Practices Bradken Engineering • RECP measures taken: • Use of less toxic sand binders • Use of better refractory materials (tripled lifespan) • Improved dry mechanical sand recovery (to 75%) • Strengthened scrap acceptance criteria • Changed melting regime • Power factor improvement » Energy savings exceeding A$ 570,000 achieved with one year pay back on investment Van Berkel (2007), Cleaner Production and Eco-Efficiency , Int Hdbk on Ent Techn Man February 2017 RECP Introductory Training 7 Metal Finishing Shops • Insulation of heated baths with polypropylene balls • Invested USD120, saving annually USD15,000 • Installation of water cascading system • Invested USD150, saving annually USD15,000 • Replacement of wires with jigs in electroplating • Invested USD15,000, saving annually USD12,600 February 2017 RECP Introductory Training 8 Resource Efficient and Cleaner Production (RECP) 4

Intrroductory Training in RECP Methods February 2017 and Practices Tarasima Apparels • Key measures – Installation of thermal oil heaters to cut down steam consumption – Installation of a 2-ton incineration boilers resulting in savings in natural gas consumption – Using skylights in the cutting, washing and finishing units – Installation of Electro Catalytic Reactor in Effluent Treatment Plant – Establishment of biogas plant, producing 56m 3 biogas from canteen waste www.textilepact.net February 2017 RECP Introductory Training 9 Sky High Knitwear • Key options • Economics – Installed wood based – Invested USD109,100 boiler – Annual savings – Replacing 400 lux T8 ~USD395,000 fluorescent lights (40W) • Environment with 500 lux LED tubes – 36% increase in specific (18W) energy consumption – 31% decrease in specific GHG emissions February 2017 RECP Introductory Training 10 Resource Efficient and Cleaner Production (RECP) 5

Intrroductory Training in RECP Methods February 2017 and Practices De La Paix Hotel, Luang Prabang 52% reduction of energy and water use per guest night (2012-2014) February 2017 RECP Introductory Training 11 Business Case Cost savings Productivity enhancements Quality improvements Organizational efficiency License-to-operate February 2017 RECP Introductory Training 12 Resource Efficient and Cleaner Production (RECP) 6

Intrroductory Training in RECP Methods February 2017 and Practices Resource Efficient and Cleaner Production emerged as a business response to worsening (industrial) pollution and escalating use of natural resources February 2017 RECP Introductory Training 13 replace scarcity protect resources natural recover Resource Resource reduce Efficient and Cleaner environment prevent Production Production recycle control pollution Efisiensi Sumber Daya dan Produksi Bersih disperse February 2017 RECP Introductory Training 14 Resource Efficient and Cleaner Production (RECP) 7

Intrroductory Training in RECP Methods February 2017 and Practices Efisiensi Sumber Daya dan Produksi Bersih • Finding and implementing ways to – Improve productive use of materials, water and energy; • Thereby – Reduce the generation of waste, effluent and emissions; • Thereby – Improve well being of employees, consumers and community; • Thereby • ……. • …….. February 2017 RECP Introductory Training 15 Productive output per unit of resource consumption Pollution intensity per unit of productive output February 2017 RECP Introductory Training 16 Resource Efficient and Cleaner Production (RECP) 8

Intrroductory Training in RECP Methods February 2017 and Practices RECP Issues February 2017 RECP Introductory Training 17 Resource Efficient and Cleaner Production can be implemented through – combinations of – different prevention practices February 2017 RECP Introductory Training 18 Resource Efficient and Cleaner Production (RECP) 9

Intrroductory Training in RECP Methods February 2017 and Practices Peningkatan Peningkatan Substitusi Pengenda- Bahan lian Proses Tata Kelola Modifikasi Area Kerja Peralatan Modifikasi Penggan- Penggan- Produk tian Teknologi Teknologi Guna Ulang Guna Ulang Pemanfaatan Pemanfaatan Dan Daur Produk Ulang di Samping Lokasi Sendiri Lokasi Sendiri February 2017 RECP Introductory Training 19 • Typical solutions – Switch off what is not in use – Repair what needs reparation • Maintain a clean, organized and – Keep workplace organized and productive workplace to eliminate clean avoidable ‘ wastage’ – Minimize and manage inventory – Confirm right way for all tasks – Keep staff motivated February 2017 RECP Introductory Training 20 Resource Efficient and Cleaner Production (RECP) 10

Intrroductory Training in RECP Methods February 2017 and Practices • Typical solutions – Use renewable energy • Choose inputs that are efficient, – Use sustainably-sourced effective and/or pose minimum renewable materials harm to the environment and – Use of recycled materials, health water and energy – Use fit for purpose materials – Use less harmful substances – Source locally February 2017 RECP Introductory Training 21 • Typical solutions • – Standard operating Monitor and control processes and equipment so that they always run at procedures and process highest efficiency and with lowest monitoring wastage – Sub-metering water, energy and materials – Preventive maintenance February 2017 RECP Introductory Training 22 Resource Efficient and Cleaner Production (RECP) 11

Intrroductory Training in RECP Methods February 2017 and Practices • Typical solutions – Insulation • Make existing equipment more – Proper alignment of efficient and less wasteful production line – Improve process temperature, pressure, speed, mixing – Automatic switch off & level controls – Combine process steps in same equipment February 2017 RECP Introductory Training 23 • Typical solutions – Efficient boilers, motors, fans, • Change over to new technology compressors etc. that is more efficient or produces – Change of core process, e.g. less waste chemical to mechanical cleaning – Equipment with integrated recovery loops – Advanced separation processes – Solar dryers, heaters and lighting February 2017 RECP Introductory Training 24 Resource Efficient and Cleaner Production (RECP) 12

Intrroductory Training in RECP Methods February 2017 and Practices Practices Typical solutions • Use previously ‘wasted’ material, • Countercurrent or cascaded energy and/or water for similar or use of water and energy alternative purpose in company • Condensate and heat recovery • Reuse of incoming packaging for outgoing products February 2017 RECP Introductory Training 25 Typical solutions • Provision of used cooling • Convert a previous ’ waste ’ for a water for external heating or useful use elsewhere cooling purposes • Segregate recyclables for external recycling and resource recovery, such as composting • Symbiosis - use waste material for new product development February 2017 RECP Introductory Training 26 Resource Efficient and Cleaner Production (RECP) 13

Recommend

More recommend