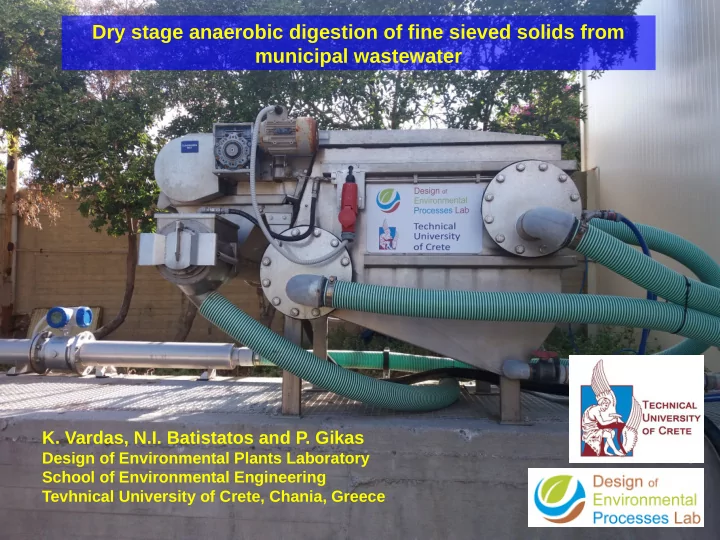

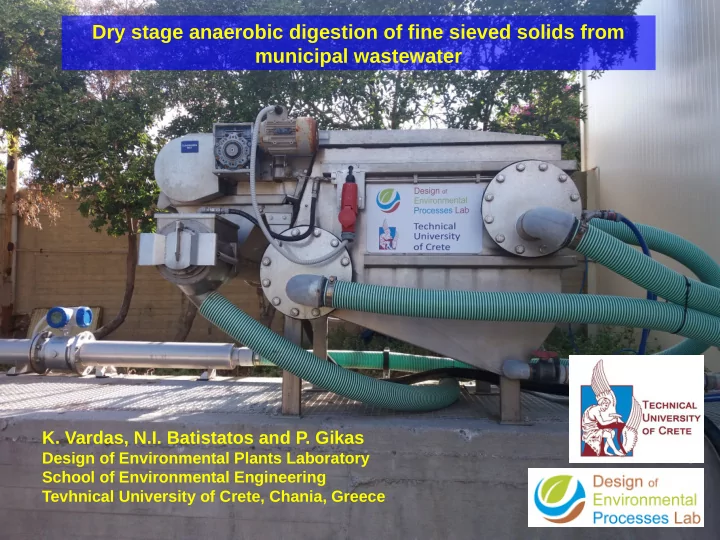

Dry stage anaerobic digestion of fine sieved solids from municipal wastewater K. Vardas, N.I. Batistatos and P. Gikas Design of Environmental Plants Laboratory School of Environmental Engineering Tevhnical University of Crete, Chania, Greece

Topics The microsieving process Fine sieved solids characteristics Dry vs wet stage anaerobic digestion Experimental setup Experimental findings School of Environmental Engineering Technical University of Crete

How It Works Microscreen - Operating principle School of Environmental Engineering T echnical University of Crete

Microscreen a. Microscreen with open housing b. Sludge removal (~45% TS) c. Microscreen cloth (100-350μm openings) a b c

Microscreen (Patra, Greece) School of Environmental Engineering T echnical University of Crete

Microsceen: Operation Solids removal Solids compaction

How It Works Inlet TSS ( ○ ) and TSS at the outlet of microscreen ( □ ) and at the outlet of primary clarifier ( ∆ ) School of Environmental Engineering T echnical University of Crete

How It Works Inlet COD ( ○ ) and COD at the outlet of microscreen ( □ ) and at the outlet of primary clarifjer ( ∆ ) School of Environmental Engineering T echnical University of Crete

Selected removal of large particles through microscreening -50% TSS Final particle concentration after primary clarification - 5 0 % T S S Initial particle concentration Final particle School of Environmental Engineering concentration after T echnical University of Crete microscreening

Particle size distribution in municipal wastewater, prior and after microscrening Inlet Outlet 6 100 weight (%) 5 80 4 60 3 (%) 40 2 20 1 0 0 0,01 0,1 1 10 100 1000 0,01 0,1 1 10 100 1000 particle size (μm) particle size (μm) It is observed selective removal of the larger particles School of Environmental Engineering Increase of wastewater biodegradability T echnical University of Crete

How It Works Footprint requirements Wastewater fmow: 4000m 3 /d: Microscreen footprint: 4 m 2 Clarifjer footprint: 82 m 2 1 ÷ 20 School of Environmental Engineering T echnical University of Crete

Application of microscreening, upstream of various wastewater treatment processes SBR MBR MBBR Microscreen Activated sludge Natural School of Environmental Engineering systems T echnical University of Crete

Fine Sieved Solids (FSS) characteristics Managed as solids Total solids: 40-45% Volatile solids: 85-90%of TS C/N about: 20 High Heating Value: 22-24MJ/kg School of Environmental Engineering Technical University of Crete

Biosolids: Gasification versus anaerobic digestion* Potential for net electrical energy production Gasifjcation Anaerobic digestion 2 : 1 * P . Gikas, 2014, Environmental T echnology, 35(17), 2140-2146 School of Environmental Engineering T echnical University of Crete

Dry stage anaerobic digestion Advantages-Disadvantages (compared to wet stage) - Requires smaller space compared to wet stage - Tolerant to the presence of solid particles (e.g.: sand, fibers) - Less complicated compared with wet stage - Requires less maintenance - Requires less electromechanical equipment (pumps, agitators, feeding equipment) - Lower operational cost - A batch rather than a continuous process - Requires advanced processes for loading-unloading - Insufficient mixing - Requires re-inoculation in every cycle - Lower biogas yield - Requires advanced design School of Environmental Engineering Technical University of Crete

Experimental Set up A. Microsieve (1000 m 3 /d) B. Blower (air knife for solids-screen separation, 5 bar) C. Control Panel-PLC School of Environmental Engineering Technical University of Crete

Experimental Set up a) Digital manometer b) Reaction bottles School of Environmental Engineering c) Portable gas analyzer Technical University of Crete

Experimental Set up Mechanical stirring set-up PSS sample: Sample Ratio Inoculum/sludge TS(%) From Rethymno, Greece, WWTP Solids concentration: 40% 11% 1 1 Volatile Solids: 89% (of TS) 14% 2 1/2 C/N: 20 19% 3 1/4 Inoculum: 28% 4 1/13 From Chania, Greece, WWTP Solids concentration: 40% Volatile Solids: 89% (of TS) School of Environmental Engineering Technical University of Crete

Experimental fjndings 120 1600 Cumulative biogas prouction (ml biogas/gVSdestroyed) 1400 Daily biogas production (ml biogas/gVSdestroyed) 100 1200 14% 19% 80 1000 11% 14% 19% 11% 60 800 600 40 400 20 200 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 Time (days) Optimum biogas production at 11% TS concentration The maximum daily biogas production (for 11%TS) achieved after 11 days At 19% TS concentration biogas yield was 30% of that produced by the 11% TS School of Environmental Engineering Technical University of Crete

Conclusions Microsieving produces biosolids with high solids content (40-45%), high volatile content (85-90% of TS) and C/N of about 20 Dry stage anaerobic digestion at 11% solids content exhibited the highest biogas production yield Maximum biogas production was achieved after 11 days from inoculation Agitation issues are to be resolved School of Environmental Engineering Technical University of Crete

Thank you for your attention petrosgikas@gmail.com / petros.gikas@enveng.tuc.gr

Recommend

More recommend