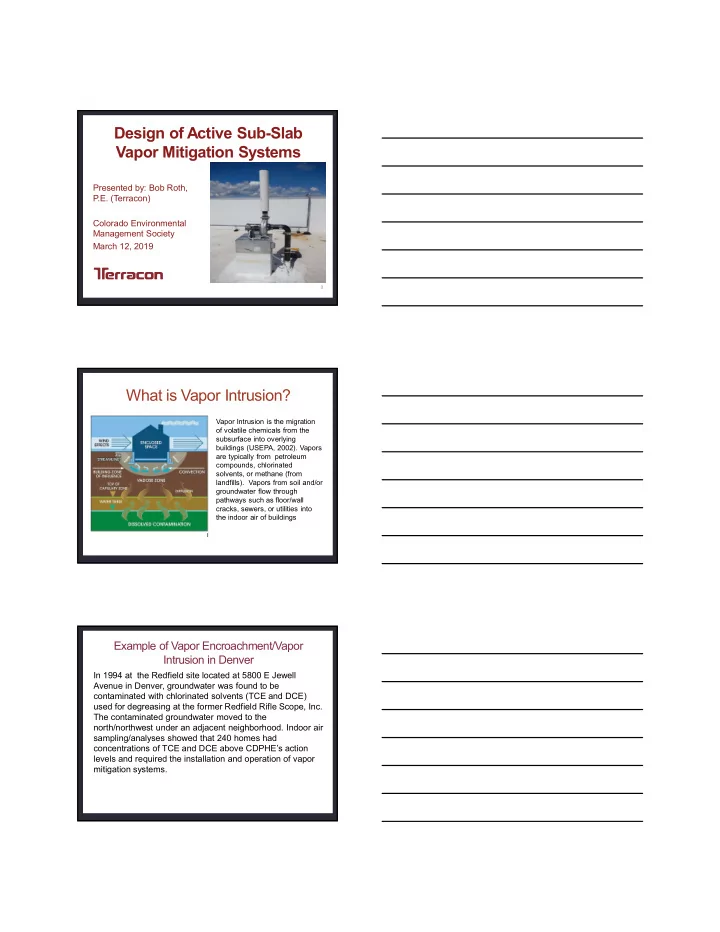

Design of Active Sub-Slab Vapor Mitigation Systems Presented by: Bob Roth, P.E. (Terracon) Colorado Environmental Management Society March 12, 2019 1 What is Vapor Intrusion? Vapor Intrusion is the migration of volatile chemicals from the subsurface into overlying Simply, it is the migration of buildings (USEPA, 2002). Vapors contaminant vapors from are typically from petroleum soil, groundwater, or compounds, chlorinated solvents, or methane (from preferential conduit onto landfills). Vapors from soil and/or the subject property groundwater flow through (typically seen as pathways such as floor/wall petroleum compounds or cracks, sewers, or utilities into chlorinated solvents). the indoor air of buildings Example of Vapor Encroachment/Vapor Intrusion in Denver In 1994 at the Redfield site located at 5800 E Jewell Avenue in Denver, groundwater was found to be contaminated with chlorinated solvents (TCE and DCE) used for degreasing at the former Redfield Rifle Scope, Inc. The contaminated groundwater moved to the north/northwest under an adjacent neighborhood. Indoor air sampling/analyses showed that 240 homes had concentrations of TCE and DCE above CDPHE’s action levels and required the installation and operation of vapor mitigation systems. 1

Why be concerned with vapor intrusion? Primary Reason Protect the health and welfare of building occupants Secondary Reasons Compliance with federal and state regulations. Avoid complaints of odors from building occupants. Avoid questions from occupants: Is the air safe for us to breathe? Is the air safe for my children to breathe? Will this affect our property value? Avoid relocating occupants (cost and lost revenue). Avoid occupants retaining third party to conduct vapor investigations. Avoid legal action. More cost effective to engineer and install a vapor mitigation system in new construction than in an existing building. 4 Vapor Intrusion Health Risks Acute and Chronic Effects Petroleum vapors (typically benzene, toluene, ethyl benzene, xylenes, and other gasoline constituents): Cancer, nervous system, liver, and explosive conditions. Chlorinated solvent vapors: Cancer, birth defects, nerve damage, adverse effects on immune system. Methane: Explosive, headaches, weakness, nausea. 5 Vapor Intrusion Regulations CERCLA - authorizes enforcement and cleanup of substances that present danger to public health and welfare. OSWER Directive 9200.2-84 - mandates remedial action to prevent risks associated with vapor intrusion. Subsurface intrusion component added to Hazard Ranking System – EPA Rule Addition February 8, 2017 RCRA - authorizes litigation to force cleanup of contamination that could endanger health or environment CDPHE’s Indoor Air Guidance is used to evaluate indoor air exposure pathway, calculating risk-based air concentrations, indoor air sampling/analysis, and collection of sub-slab vapor samples. Department of Labor and Employment, Division of Oil and Public Safety UST Program. 6 Who is liable? Building owner, operator, and real estate 2

7 Passive vs. Active Vapor Mitigation Systems Passive VMSs rely on natural venting due to changes in atmospheric pressure or use a mechanical ventilator powered by the wind which induces a low level vacuum to extract the vapors beneath the floor slab and discharge to the atmosphere. Active VMSs use a vacuum blower to extract the vapors beneath the floor slab and discharge the vapors to the atmosphere. 8 Required Components of Passive VMS Sub-slab soil gas collectors (slotted or perforated pipe) installed in gravel Soil gas collector headers (solid pipe) to convey vapors to exhaust piping 4-inch minimum layer of sub-slab gravel over soil gas collectors Vapor retarder membrane over sub-slab gravel Vertical exhaust piping to convey vapors to discharge point over roof 9 3

10 11 12 4

VMS Membranes VMS membranes typically made of HDPE Usually 40 to 60 mil thickness VMS membranes less than 30 mil are not durable enough to prevent significant damage during placement of reinforcing steel and concrete, and are not recommended in sub-slab applications (EPA, Engineering Issue: Indoor Air Vapor Intrusion Mitigation Approaches ). 13 Sheet Membrane 14 VMS Composite Membrane 15 5

16 17 18 6

19 Soil Gas Collector Layout 20 VMS Risers VMS vertical risers convey collected vapors to roof and discharge the vapors to the exterior of the building. 21 7

Use of Mechanical Ventilators for Passive VMSs A wind-powered mechanical ventilator is installed at the outlet of vertical risers to induce a low-level vacuum below the floor slab, extract vapors from beneath the slab, and convey them to the outlet of the vertical riser 22 Flow Monitoring – Passive VMS with Mechanical Ventilator 23 Location of Vertical Risers Relative to Fresh Air Intakes Building openings (windows, doors, other), fresh air intakes, and HVAC intakes should be outside a 15 ft radius of the outlets of VMS vertical risers (ASHRAE Standard 62.1-2004) 24 8

Location of Outlets of Vertical Risers Relative to Electrical Equipment When Vapors are Explosive If area around riser outlet is rated as Class 1, Division 1 per NEC, electrical equipment within 5 feet of outlet shall be rated same. If area around riser outlet is classified as Class 1, Division 2, electrical equipment within 10 feet of outlet shall be rated same. 25 Passive VMS Coffee Shop – 2,000 sf 26 Passive VMS for 5-Story Mid Rise Office – 34,000 sf 27 9

Passive VMS for 5-Story Mid Rise Commercial/Residential – 68,000 sf 28 Questions often asked by Active VMS designers What to do for new and existing buildings with sub-slab soils with soil gas VOC concentrations exceeding VISLs? What guidance documents do I use? What vacuum is needed under the slab to capture vapors in order to protect building occupants? What flow rate do I select to extract the soil vapor? How do I size a vacuum blower? ANSWERS? 29 Primary Design Criterion for Active Sub-Slab VMS Maintain sub-slab vacuum to achieve depressurization of approximately 4 – 10 Pascals (0.016 – 0.040 inches water) over the building footprint. (EPA, 2008. Indoor Air Vapor Intrusion Mitigation Approaches, EPA/600/R-08-115, October 2008) 30 10

State Requirements for Sub-Slab Vacuum Web search showed 10 states with VI Guidance Documents Only four states cite requirement for minimum sub-slab vacuum: Minnesota: 3 to 5 Pa (0.012 – 0.02“ H2O) New Jersey: 1 Pa (0.004” H2O) North Carolina: 4 Pa (0.016” H2O) Massachusetts: no less than 0.5 Pa (0.002” H2O) (recommendation only) 31 Flow Rate Design Criterion for Active Sub- Slab Methane Mitigation Systems Capable of ventilating the sub-slab gravel voids at a rate of three (3) vapor changes per hour. (Methane Seepage Regulations – Division 71, Los Angeles Building Code) 32 Sub-slab vapor flow paths induced by vacuum applied to sub-slab gravel. Case 1: Flow from vadose zone with negligible flow from sides. 33 11

Q = kiA/u = k dP/(dx) A/u Where: Q = flow rate of a fluid through a medium A = the area of the medium k = permeability of the medium u = dynamic viscosity of the fluid dP = applied pressure to the fluid dx = thickness of the medium 34 Sub-slab vapor flow rate vs. sub-slab vacuum for different soil types. Case 1: Flow from vadose zone with negligible flow from sides. Flow per 1000 sf area 35 Case 2 – Flow from Surface with Negligible Flow from Vadose Zone 36 12

Sub-slab vapor flow rate vs. applied vacuum for different soil types. Case 2: Flow from soil surface with negligible flow from vadose zone. Flow per 1000 sf 37 Case 3 – Flow from Soil Surface and Vadose Zone 38 Sub-slab vapor flow rate vs. applied vacuum for different soil types. Case 3: Flow from soil surface and vadose zone. Flow per 1000 sf 39 13

Case Studies – Flow/Area vs. Sub-Slab Vacuum 40 Flow/Area vs. Sub-Slab Vacuum 41 F/A Ratio to Achieve Sub-Slab Vacuum of 4 Pa Using data base, find F/A required to achieve sub- slab vacuum of 4 Pa (0.016 inch water) F/A = 22.9 x 0.016 F/A = 0.37 cfm/1000 sf Assume FS of 2 F/A = 0.8 cfm/1000 sf (say 1 cfm/1000 sf) 42 14

Fan Sizing (ANSI/AARST) 43 F/A Ratios based on ANSI/AARST Fans 44 Flow/Area Ratio Based on Sub-Slab Gravel Void Volume Changeouts/Hour 45 15

Single Horizontal Soil Gas Collector Layout (ROI = 20 feet, Area = 2,400 sf) 46 A2FAC1A3.pdf Manifolded Soil Gas Collectors (ROI = 30 feet, Area = 105, 000 sf 47 What do I need to consider when designing a VMS that uses long (> 75 feet) horizontal soil gas collectors? 48 16

Common Design Approach: If I use equal spacing between the slots or perforations in my sub-slab vapor collection piping, the vapor flow will be equal along the axis of the piping. IDEALIZED SUB-SLAB VACUUM ISOPLETHS AROUND VAPOR COLLECTION LA TERAL Sub-slab vacuum isopleths and vapor streamlines for a vapor collection lateral 17

Recommend

More recommend