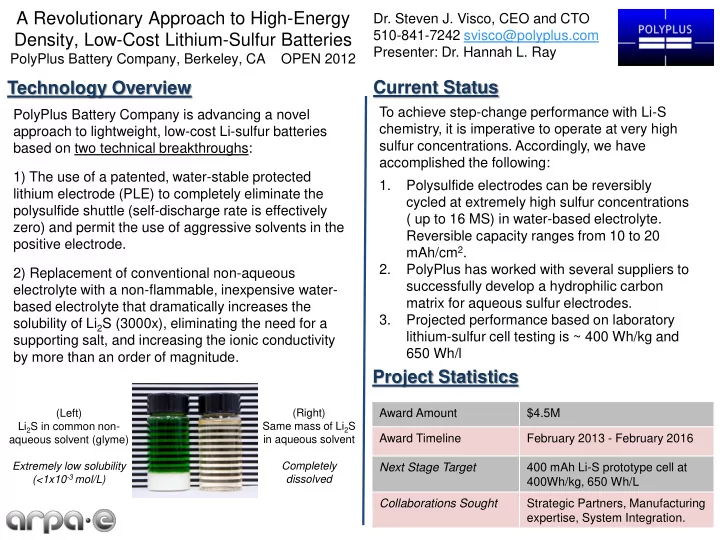

A Revolutionary Approach to High-Energy Dr. Steven J. Visco, CEO and CTO 510-841-7242 svisco@polyplus.com Density, Low-Cost Lithium-Sulfur Batteries Presenter: Dr. Hannah L. Ray PolyPlus Battery Company, Berkeley, CA OPEN 2012 Current Status Technology Overview To achieve step-change performance with Li-S PolyPlus Battery Company is advancing a novel chemistry, it is imperative to operate at very high approach to lightweight, low-cost Li-sulfur batteries sulfur concentrations. Accordingly, we have based on two technical breakthroughs: accomplished the following: 1) The use of a patented, water-stable protected 1. Polysulfide electrodes can be reversibly lithium electrode (PLE) to completely eliminate the cycled at extremely high sulfur concentrations polysulfide shuttle (self-discharge rate is effectively ( up to 16 MS) in water-based electrolyte. zero) and permit the use of aggressive solvents in the Reversible capacity ranges from 10 to 20 positive electrode. mAh/cm 2 . 2. PolyPlus has worked with several suppliers to 2) Replacement of conventional non-aqueous successfully develop a hydrophilic carbon electrolyte with a non-flammable, inexpensive water- matrix for aqueous sulfur electrodes. based electrolyte that dramatically increases the 3. Projected performance based on laboratory solubility of Li 2 S (3000x), eliminating the need for a lithium-sulfur cell testing is ~ 400 Wh/kg and supporting salt, and increasing the ionic conductivity 650 Wh/l by more than an order of magnitude. Project Statistics Award Amount $4.5M (Left) (Right) Li 2 S in common non- Same mass of Li 2 S Award Timeline February 2013 - February 2016 aqueous solvent (glyme) in aqueous solvent Extremely low solubility Completely Next Stage Target 400 mAh Li-S prototype cell at (<1x10 -3 mol/L) dissolved 400Wh/kg, 650 Wh/L Collaborations Sought Strategic Partners, Manufacturing expertise, System Integration.

Major Accomplishments • PolyPlus has developed aqueous polysulfide electrodes that demonstrate reversible cycling at exceptionally high sulfur concentration (up to 16 MS). • PolyPlus has demonstrated long-term stability of the protected electrode (solid electrolyte) against aqueous polysulfides at high pH, and excellent chemical stability of highly concentrated aqueous polysulfides (no evidence of precipitation for several months). • We have successfully identified a number of suppliers for high porosity/high surface area carbon supports that are sufficiently hydrophilic to be used with aqueous polysulfides. 2

Lessons Learned • It’s important to have a well integrated team that communicates often and well (electrochemistry, chemistry, materials, mechanical engineering, etc.) • Prototype engineering for new chemistries in non-trivial (start early) • Pushing the envelope on performance goals helps identify key fundamental and scientific issues limiting performance. • The literature is often wrong. • Having the ability to write patents internally allows you to move quickly towards protecting intellectual property, and should lead to stronger IP. • Build many, many, cells. Reproducibility is critical to moving the needle. • It helps to have big friends: When trying to convince large companies to modify existing products for new applications (like ► Li-S batteries), the ability to call in the big guns to make a phone call helps. 3

Collaborations specifically looking for – technical & T2M • PolyPlus is always interested in strategic partners that can either accelerate the manufacture and scaling of our step-change battery technology, or have an internal strategic need for this advance. • A key component in aqueous Li-S technology is the high porosity carbon support. Although we have identified several companies that make such materials, we are particularly interested in alternative high porosity and high surface area hydrophilic carbons that can be scaled at low cost. • We are still pre-revenue and therefore have an enduring need for funding and/or strategic investment. 4

Value Proposition 5

Recommend

More recommend