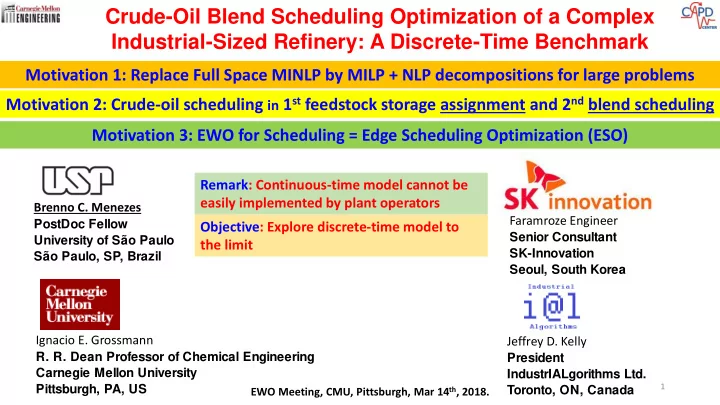

Crude-Oil Blend Scheduling Optimization of a Complex Industrial-Sized Refinery: A Discrete-Time Benchmark Motivation 1: Replace Full Space MINLP by MILP + NLP decompositions for large problems Motivation 2: Crude-oil scheduling in 1 st feedstock storage assignment and 2 nd blend scheduling Motivation 3: EWO for Scheduling = Edge Scheduling Optimization (ESO) Remark: Continuous-time model cannot be easily implemented by plant operators Brenno C. Menezes Faramroze Engineer PostDoc Fellow Objective: Explore discrete-time model to Senior Consultant University of São Paulo the limit SK-Innovation São Paulo, SP, Brazil Seoul, South Korea Ignacio E. Grossmann Jeffrey D. Kelly R. R. Dean Professor of Chemical Engineering President Carnegie Mellon University IndustrIALgorithms Ltd. 1 Pittsburgh, PA, US Toronto, ON, Canada EWO Meeting, CMU, Pittsburgh, Mar 14 th , 2018.

Whole Scheduling: from Crude-Oils to Fuels 1996: Lee, Pinto, Grossmann and Park (MILP), discrete-time Crude-Oil Scheduling Problem 2004: Randy, Karimi and Srinivasan (MILP), continuous-time Fuel gas 2009: Mouret, Grossmann and Pestiaux: MILP+NLP continuous-time LPG 2014: Castro and Grossmann: MINLP ; MILP+NLP, continuous-time NHT 2015: Cerda, Pautasso and Cafaro: MILP+NLP, continuous-time Naphtha Charging or REF Transferring or (336h: 14 days; binary ≈ 4,000; continuous ≈ 6,000; constraints ≈ 100K; CPU(s) ≈ 500) B Feed Tanks Gasoline Feedstock Tanks Goal: solve a 1 week refinery scheduling for the 3 rd biggest KHT L Kerosene E refinery among 635 in operatiojn DHT Diesel N Receiving or Diluent S RFCC Storage Tanks Current Benchmark Fuel oil Relax y [0,1] FCC MINLP as (0,1) in NLP VDU Asphalt DC DICOPT (5,000 binary variables) Crude-to-Fuel Transformation Crude-Oil Management Blend-Shop Crude Crude Fuel MINLP -> MILP + NLP Hydrocarbon Flow Transferring Dieting Blending Refinery Units Crude Fuel Receiving Deliveries 2 EWO Meeting, Sep 20 th , 2017.

Whole Scheduling: from Crude-Oils to Fuels 1996: Lee, Pinto, Grossmann and Park (MILP), discrete-time Crude-Oil Blend Scheduling Problem CBSO 2004: Randy, Karimi and Srinivasan (MILP), continuous-time Fuel gas FSA FSA 2009: Mouret, Grossmann and Pestiaux: MILP+NLP continuous-time LPG 2014: Castro and Grossmann: MINLP ; MILP+NLP, continuous-time NHT 2015: Cerda, Pautasso and Cafaro: MILP+NLP, continuous-time Naphtha Charging or REF Transferring or (336h: 14 days; binary ≈ 4,000; continuous ≈ 6,000; constraints ≈ 100K; CPU(s) ≈ 500) B Feed Tanks Gasoline Feedstock Tanks KHT L Goal: solve the refinery scheduling for a week (38 crude, 2 Kerosene E pipelines, 23 storage tanks, 11 feed tanks, 5 CDUs) DHT Diesel N Receiving or Diluent S 1 st Feedstock Storage RFCC Storage Tanks (MILP) MINLP -> MILP + NLP Fuel oil FCC Assignment (FSA) VDU Asphalt DC Minimize the Quality Variation Feedstocks -> Storage Tanks Reduces optimization search space for further scheduling Crude-to-Fuel Transformation Crude-Oil Management Blend-Shop 2 nd Crude Blend Scheduling Crude Crude Fuel (MILP+NLP) Optimization (CSBO) Hydrocarbon Flow Transferring Dieting Blending (Menezes, Kelly & Grossmann, 2015) Yields Includes logistics details Rates (crude diet, fuel recipes, conversion) Refinery Units Crude Fuel PDH Decomposition (logistics + quality problems) Receiving Deliveries 1. JD Kelly, BC Menezes, IE Grossmann, F Engineer, 2017, FOCAPO. 3 EWO Meeting, Sep 20 th , 2017. 2. JD Kelly, BC Menezes, F Engineer, IE Grossmann, 2017, FOCAPO.

Automated in Python/IMPL: FSA + Root + CBSO with Factors FSA root y jit : Current assignments 1 st : Feed tanks to CDU; 2 nd : Storage to Feed tanks; 3 rd : Feedstock Storage Assignment x m : CDU Throughputs (varying for the remaining amount in the feed tanks and CBSO with performance term to smooth throughput) Multi-period NLP for near past, current and near future assignments Quality Logistics Quality Logistics Quality (MILP) Setups “Score” Setups Yields Qualogistics Factors Quality Sub-Solver (NLP) Yields (for CDU) Factors (for Storage to Feed tanks) Logistics Sub-Solver (MILP) 4 EWO Meeting, Sep 20 th , 2017.

STEPS 2016 (real crude-oil topology + simplified towers) 2018 (Full crude-oil topology and Full Refinery) 2017 (simple crude-oil topology + towers in cascade) EWO Meeting, Sep 20 th , 2017.

2017 (simple crude-oil topology + towers in cascade) Blender updated as [0,1] from the NLP PDH converges to 3% after 4 iterations 6

2017 (simple crude-oil topology + towers in cascade) Blender recipes updated from the NLP PDH converges to 3% after 3 iterations 7

Reproduce an Industrial-Sized Problem using Factors Units: 5 CDUs without modes + 4 Blenders + VDU + 2 RHDS + 2 RFCC Tanks: 20 storage and 10 feed; 2 intermediate for each unit 5 days: 120-hours discretized into 1-hour time-period duration The logistics problem (MILP): 45,753 continuous + 28,543 binary variables 8,612 equality and 72,368 inequality constraints Non-Zeros: 628,795; Degrees-of-freedom: 63,427 CPU(s): 170 seconds (2.83 min) in 8 threads CPLEX 12.6. The quality problem (NLP): 121,394 continuous variables 99,099 equality and 516 inequality constraint Non-Zeros: 125,462; Degrees-of-freedom: 22,295 CPU(s): 933 seconds (15.55 min) in the IMPL’ SLP engine linked to CPLEX 12.6. MILP-NLP gap: 3% after 5 PDH iterations. IMPL (Industrial Modeling and Programming Language) using Intel Core i7 machine at 2.7 Hz with 16GB of RAM 8 EWO Meeting, Sep 20 th , 2017.

EWO for Scheduling as Edge Scheduling Optimization 2018 (Full crude-oil topology and Full Refinery) Franzoi R.E.; Menezes B.C.; Kelly J.D.; Gut J.W., Effective Scheduling of Complex Process-shops using Online Parameter Feedback in Crude-oil Refineries, 1-5 July, PSE 2018, San Diego, 2018. (In Press) Menezes, B.C.; Kelly, J.D.; Grossmann, I.E., Logistics Optimization for Dispositions and Depooling of Oil-refinery Distillates: closing the production scheduling and distribution gap, 10-13 June, ESCAPE 2018, Graz, 2018. (In Press) EWO Meeting, Sep 20 th , 2017.

Conclusion Novelty: • Segregates crude management in storage assignment 1 and crude blend scheduling. 2 • Phenomenological decomposition in logistics (MILP) and quality (NLP) problems applied in a scheduling problem updating crude-oil recipes and distillate yields. Impact for industrial applications: • UOPSS modeling, pre-solving, and parallel processing, reverse polish notation, complex number for derivatives, among others, solved for the 1 st time a highly complex refinery scheduling. (MILP 50K binary variables and NLP 120K continuous with 60% NLP) 1. JD Kelly, BC Menezes, IE Grossmann, F Engineer, 2017, FOCAPO. 2. JD Kelly, BC Menezes, F Engineer, IE Grossmann, 2017, FOCAPO. 10 EWO Meeting, Sep 20 th , 2017.

Thank You Q?&A! www.openIMPL.com 11

Recommend

More recommend