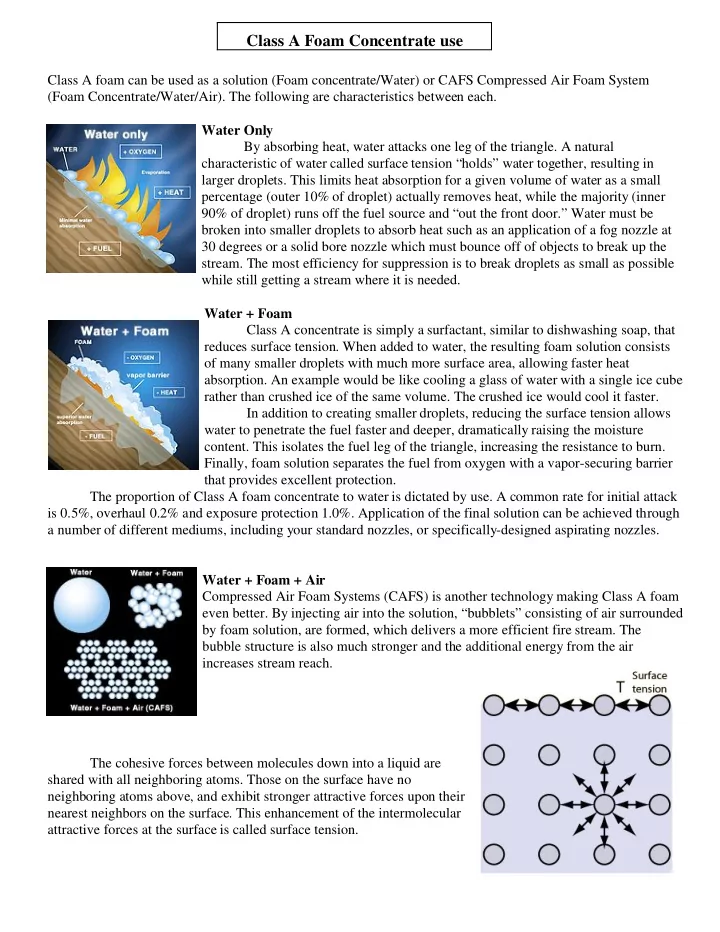

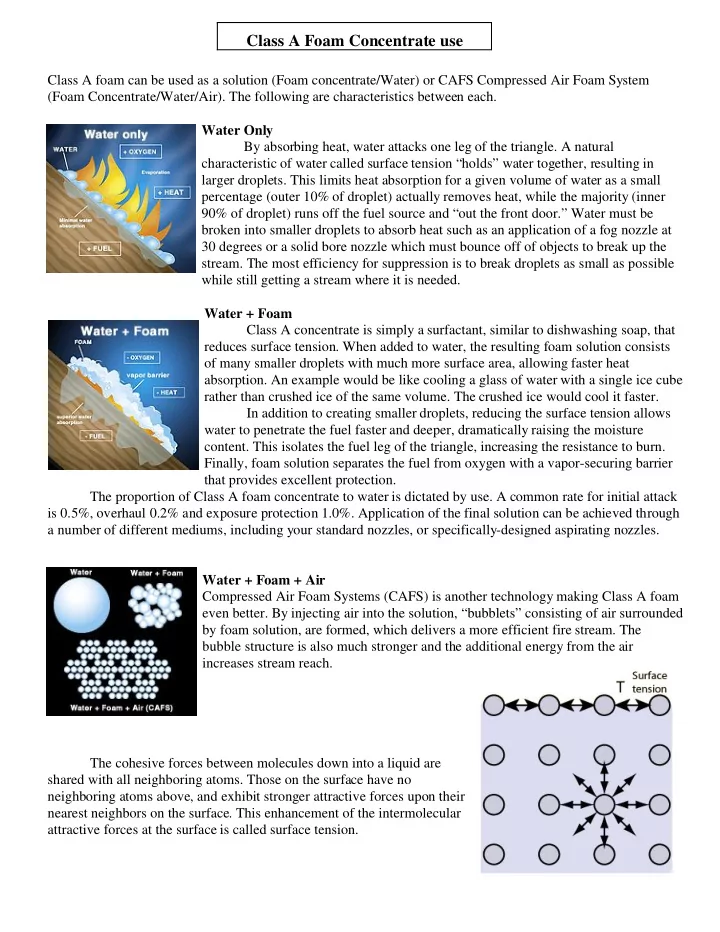

Class A Foam Concentrate use Class A foam can be used as a solution (Foam concentrate/Water) or CAFS Compressed Air Foam System (Foam Concentrate/Water/Air). The following are characteristics between each. Water Only By absorbing heat, water attacks one leg of the triangle. A natural characteristic of water called surface tension “holds” water together, resulting in larger droplets. This limits heat absorption for a given volume of water as a small percentage (outer 10% of droplet) actually removes heat, while the majority (inner 90% of droplet) runs off the fuel source and “out the front door.” Water must be broken into smaller droplets to absorb heat such as an application of a fog nozzle at 30 degrees or a solid bore nozzle which must bounce off of objects to break up the stream. The most efficiency for suppression is to break droplets as small as possible while still getting a stream where it is needed. Water + Foam Class A concentrate is simply a surfactant, similar to dishwashing soap, that reduces surface tension. When added to water, the resulting foam solution consists of many smaller droplets with much more surface area, allowing faster heat absorption. An example would be like cooling a glass of water with a single ice cube rather than crushed ice of the same volume. The crushed ice would cool it faster. In addition to creating smaller droplets, reducing the surface tension allows water to penetrate the fuel faster and deeper, dramatically raising the moisture content. This isolates the fuel leg of the triangle, increasing the resistance to burn. Finally, foam solution separates the fuel from oxygen with a vapor-securing barrier that provides excellent protection. The proportion of Class A foam concentrate to water is dictated by use. A common rate for initial attack is 0.5%, overhaul 0.2% and exposure protection 1.0%. Application of the final solution can be achieved through a number of different mediums, including your standard nozzles, or specifically-designed aspirating nozzles. Water + Foam + Air Compressed Air Foam Systems (CAFS) is another technology making Class A foam even better. By injecting air into the solution, “bubblets” consisting of air surrounded by foam solution, are formed, which delivers a more efficient fire stream. The bubble structure is also much stronger and the additional energy from the air increases stream reach. The cohesive forces between molecules down into a liquid are shared with all neighboring atoms. Those on the surface have no neighboring atoms above, and exhibit stronger attractive forces upon their nearest neighbors on the surface. This enhancement of the intermolecular attractive forces at the surface is called surface tension.

What do you plan to do with the foam solution? Mop-up?.... Direct Attack in a structure fire?....... coat a house during an Urban Interface Fire? Each operation will make different use of foam concentrate amounts, mixtures, and how the finished product performs. First we will look at the range of foam characteristics..... Ratio Foam Description % Drainage Rate FOAM SOLUTION .1 VERY FAST Clear to milky fluid Lacks bubble structure 1:1 Mostly water WET FOAM .2-.3 Watery FAST Large to small bubbles Lacks body/Drains fast FLUID FOAM Similar to watery shaving cream MODERATE Medium to small bubbles .5 Flows easily Moderate draining DRY FOAM Similar to shaving cream Medium to small bubbles 1.0 20:1 SLOW Mostly air Clings to vertical surfaces Slow draining Mop-Up Mop-Up during structure or wildland fires has a basic need.... reduce surface tension of the water so it can penetrate fuels deeper and cool faster. Foam that consists of bubbles is not needed because bubbles are not what is penetrating into the fuel. Providing .1% foam solution will break the surface tension and greatly aid in reducing mop-up time. Providing a higher % rate will only use more foam concentrate than needed as explained below . Once surface tension is broken by a .1% foam solution, it doesn’t change much after that. Doubling the percentage rate to .2% does not double the penetration/cooling effect. .2% only uses twice as much foam concentrate as .1% with a minuscule change to surface tension. Dynes (per cm 2 ) are a unit of surface tension measurement - Mercury/480 Dynes, Plain water/around 72.8 Dynes, Water with Class A foam solution added/24-26 Dynes.

Using CAFS during mop-up may cause more of a problem. Placing a thick shaving cream blanket of foam over deep fuels such as hay, pine straw, wood, smoldering clothing and other materials may serve more to insulate the smoldering material rather than cool it. A foam blanket may serve to inhibit embers from being emitted by wind but the same wind may take the foam blanket away. Turn off the compressor and focus on foam solution at .1% and penetrate the fuels with any type nozzle. Wet Foam to Fluid Foam use for attacks Again it will be important to identify your goal. If you want to reduce surface tension during a structural or vehicle attack to allow better/faster heat absorption, the .1% setting will do just that without requirement for higher foam settings. Foam solution will penetrate fuels and will easily convert to steam/absorb heat. If you want to take the benefits of heat absorption but apply a little more bubble structure to help form a moderate foam layer, use .3%-.5% setting with any type nozzle. Flowing less than .2%-.3% foam concentrate when using compressed air will most likely produce “slug” flow. Dry Foam and exposure protection Dry foam is composed mostly of air, some water and a higher foam content to provide body. Dry foam has the qualities to “stick” or adhere to vertical surfaces and with the increased amount of well structured bubbles, provide insulating capabilities. Trapped air = Insulation. The insulation will provide more protection from embers, fill voids/cracks, and radiant heat from on approaching wildfire or other type hostile fire. This type of foam protection is not limited to the Urban Interface environment, it can be used to protect exposures during structure fires or other incidents. Foam concentrate is increased to a .8% to 1.0% which will help all the qualities mentioned.

The quality of drier, thicker Compressed Air Foam was demonstrated by the test below. Compressed Air Foam and Aspirated Foam applied simultaneously. In the photo at the left, both CAF and aspirated foam are still being applied, yet the aspirated foam is already draining off the right half of the roof. In the photo at the right, two minutes later, just after the application was completed, the aspirated foam is already exposing the structure (right side of house) while the CAF holds its blanket (left side of house). Foam Logix 5.0 System Capacity (flow capabilities from the foam concentrate pump) Use %foam Foam pump Foam pump Limiting factor of Available for capable of flowing E62 water pump non foam use Mopup- 0.1% 5000 GPM 5gpm 1000 GPM 1gpm 0gpm Overhaul 0.2% 2500 GPM 5gpm 1000 GPM 2gpm 0gpm Direct Attack 0.3% 1667 GPM 5gpm 1000 GPM 3gpm 0gpm or CAFS 0.5% 1000 GPM 5gpm 1000 GPM 5gpm 0gpm UI - CAFS 1.0% 500 GPM 5gpm 500 GPM 5gpm 500gpm Class B Fires 3.0% 167 GPM 5gpm 167 GPM 5gpm 833gpm N/A* 6.0% 83 GPM 5gpm 83 GPM 4.98gpm 917gpm *6% setting would be for 3%-6% AR-AFFF which is not used on E62. Foam solution should be started before charging the line. A 50' section of 1¾” holds appx. 6.24 gallons of water so a 200' preconnect holds appx. 25 gallons of water. 50' Length (Gallons) 200' Length (Gallons) 1¾” 6.25 (6.2475) 25 (24.99) Time not flowing solution at 100gpm rate First 15 seconds 2½” 12.75 51 Time not flowing foam solution at 250gpm rate Little over the first 12 seconds Length of Hose in Inches x .7854 x Hose Diameter 2 or Length x Pi (3.14) X Radius 2 231 231 Example for 1¾”: 600 x .7854 (1.75 2 ) = 1443.1725 cubic inches ÷ 231 = 6.2475 gallons (231 cubic inches in 1 gallon) If two 1¾” and one 2½” preconnects (200' each) are pulled and charged, 100 gallons of water is already used

When using Foam solution or Compressed Air Foam for the deck gun, only the red labeled valves controls should be open. The grey valve controls a larger “water only” valve necessary for typical deck gun flows. The booster reel can only provide foam solution, NOT COMPRESSED AIR FOAM! The “Hose Reel Blowout” air valve is only for draining the reel of water for freezing temperatures or other purposes.

During CAF operations, only the “Direct Tank Fill” intake should be used for water supply. Supplying the “Auxiliary Intake” intake (which is directly into the pump) will decrease engine RPMs needed to balance water and air pressures. Foam solution only operations can be supplied by either intake (such as mopup or Class B, 3% solution rates, if using the Class A/B foam ). Water supply during CAFS operation is maintained by opening/closing the “Direct Tank Fill” to prevent overflow. Monitor foam tank level as well as water tank level. Emptying the foam concentrate tank may require “repriming” the foam pump. Monitor Compressor Temperature! Do not operate the compressor when the temperature reaches 250°F. The compressor relies on cooling from E62's tank and recirculation to the tank. Eventually, the tank will overheat without additional or adequate water supply (Such as during “fixed” settings for air compressed tool use). A slight overflow from the tank during compressor operation is normal.

BRUSH 6

Recommend

More recommend