CFD Simulation of a Six-Strand Continuous Casting Tundish at - PowerPoint PPT Presentation

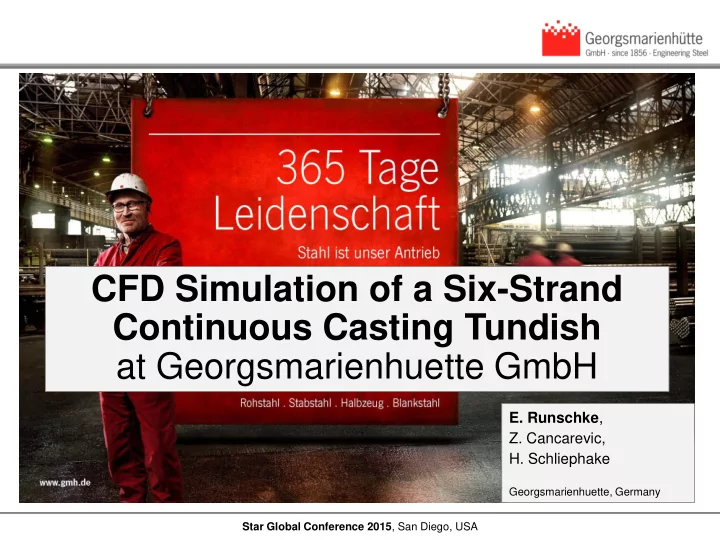

, CFD Simulation of a Six-Strand Continuous Casting Tundish at Georgsmarienhuette GmbH E. Runschke , Z. Cancarevic, H. Schliephake Georgsmarienhuette, Germany 1 Star Global Conference 2015 , San Diego, USA CONTENT , Company GMH

, CFD Simulation of a Six-Strand Continuous Casting Tundish at Georgsmarienhuette GmbH E. Runschke , Z. Cancarevic, H. Schliephake Georgsmarienhuette, Germany 1 Star Global Conference 2015 , San Diego, USA

CONTENT , Company GMH Simulation Landscape CFD Simulation: Objective and Motivation Setup Simulation Results Outlook 2

COMPANY , Manufacturer of quality and engineering steels Market leader in Germany Among Europe‘s top manufacturers Key Data 2013: 632 mil. Euro Turnover 1,316 employees 3

MARKET , Main Applications ENGINE Fracture-split conrod Piston Camshaft Crankshaft Common-Rail Injector Nozzle TRANSMISSION Gear shaft Cardan shaft Steering rack Knuckle BEARINGS Wheel hub Ball bearings 4

MARKET , References 5

SIMULATION INFRASTRUCTURE , 6

SIMULATION INFRASTRUCTURE , SimSto SimWin Windows-Cluster: Windows Server 2008 R2 @ 192 cores, 2.4 GHz, 24GB/Node Windows HPC Cluster Manager SimLin Linux-Cluster: RedHat ELS HPC @ 192 cores, 3.3 GHz, 64GB/Node Fujitsu HPC Cluster Suite 7

TECHNOLOGY , DC electric arc furnace – 130 MW 8

TECHNOLOGY , Tundish 9

OBJECTIVE AND MOTIVATION , Optimize the casting process to achieve a higher level of product quality Develop a methodology for the design and optimization of tundish at GMH Optimization of Tundish: Furniture (Dam, Weir) Tundish Working Space Size (Larger Volume) Shape (T-Shape, Delta, …) Flow Control Devices (FCDs) Tools: CFD Simulation Physical modeling 10

GEOMETRY AND STATUS QUO , Real System 3D Model MESHING SIMULATION 11

GEOMETRY AND STATUS QUO , 6 5 4 3 2 1 Historical Data: • Shape, • Size, • Ultrasonic Immersion Testing Type I (EXP) 12

SIMULATION SETUP , FULL TUNDISH 35 PARTICLES PARTICLES 30 25 Weight [t] 20 LADLE CHANGE 15 “STEADY STATE” 600s 600s 10 5 0 0 500 1000 1500 2000 2500 3000 Time [s] 13

SIMULATION SETUP , • Commercial CFD code: STAR-CCM+ Setup: k- w SST ( Menter’s Shear Stress Transport) • • Mesh: Trimmer, Prism Layer , 3 mio. volume cells • Fluid: VOF (Volume of Fluid), Particle: Lagrangian Multiphase • Particles: 10 to 65µm, density 3900kg/m³ • Strand 1 to 6: identical mass flow • Solution time 0 to 600s : “creation of fluid flow” • Solution time 600 to 600,2s: injection of 2600 particles • Solution time max. 2400s • Particles which left the system are counted • Temperature: 1530°C ( Isothermal simulation ) • The steel slag used in this work is chemically inactive and coalescence of inclusions is not considered • Physical properties: VDEh – Ladle-Benchmark 14

SIMULATION SETUP , VOF-Scene Entrainment of slag during ladle change (during fill-up) TYPE I 15

COMPARISON: TYPE I VS. TYPE II , Type I (top) vs. Type II (bottom) 16

COMPARISON: TYPE I VS. TYPE II , TYPE I 6 5 4 3 2 1 Particles in the strands @ 2400s (before Ladle Change; Normalized) 1 2 3 4 5 6 17

COMPARISON: TYPE I VS. TYPE II , TYPE II 6 5 4 3 2 1 Particles in the strands @ 2400s (before Ladle Change; Normalized) 1 2 3 4 5 6 18

EXPERIMENTS VS. SIMULATION , Relative distributions of non-metallic inclusions in individual blooms Strand 3+4, Strand 2+5, Strand 1+6 Simulation Ultrasonic Immersion Testing 19

CONCLUSION , • The numerical modelling technique was successfully used for simulation of steel flow and behavior of non-metallic inclusions in the tundish • “Small particles” (10µm) FOLLOW THE STREAM-LINES • “Medium size particles” (20µm and 40µm ) MIXED BEHAVIOR • “Coarse particles” (65µm ) FLOTATION • The steel SLAG used in this work is CHEMICALLY INACTIVE and COALESCENCE OF INCLUSIONS IS NOT CONSIDERED • ONLY Aluminum-Oxide Particles “generated” during the LADLE CHANGE PROCESS are considered as non-metallic inclusions (Exogenous inclusions derived from external sources are not considered) • Start Configuration: UNEVEN DISTRIBUTION of particles along strands • After Optimization: BALANCED DISTRIBUTION of particles along strands • TRENDS of simulation results ARE WELL REFLECTED by the experiments 20

OUTLOOK , TO-DO LIST Optimization of Tundish: Furniture (Dam, Weir) Experiments Verification Tundish Working Space Size (Larger Volume) CFD Simulation Calibration Shape (T-Shape, Delta) Physical modeling Validation Flow Control Devices (FCDs) - Ladle Change Process - Emptying Process - Refilling Process Never Ending Story … - Grade Change - Isothermal vs. Non-isothermal - Coalescence of Particles - Slag Entrapment 1. Partikel 2. Partikel 21 Ladle Change

OUTLOOK , Optimization of Tundish: Furniture (Dam, Weir) Tundish Working Space Size (Larger Volume) Shape (T-Shape, Delta) Flow Control Devices (FCDs) Continuous Casting Source: Brian G. Thomas, University of Illinois at Urbana-Champaign 22

CONCLUSION 2.0 , Until we make steel transparent we must use simulation or physical modeling. (Source: Dr. Z. Cancarevic, Georgsmarienhuette) 23

, 24

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.

![AAPICO HITECH PLC [AH] Presentation for FS 2018 financial statements Opportunity Day 28 March](https://c.sambuz.com/147567/aapico-hitech-plc-ah-s.webp)